Welding current source

A technology of welding current and AC voltage source, applied in the field of invention, can solve problems such as large cost, and achieve the effect of low-cost manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

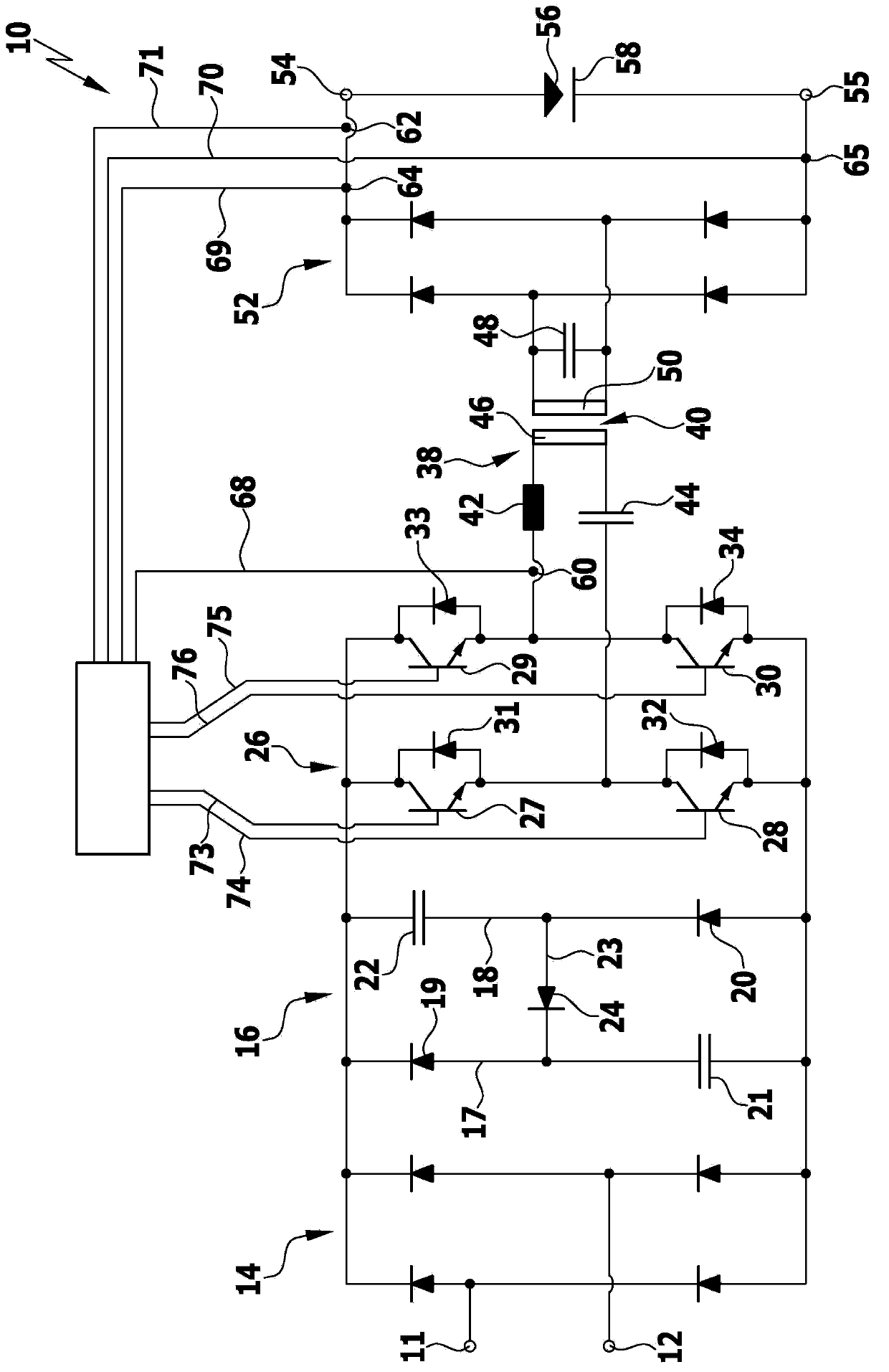

[0024] exist figure 1A simplified block diagram of a welding current source according to the invention is schematically shown in , which is designated as a whole by the reference numeral 10 . It comprises two voltage supply terminals 11 , 12 which can be connected to a single-phase alternating voltage source, in particular to a common voltage supply network. The two voltage supply terminals 11 , 12 form the input of a first rectifier circuit 14 , which in the exemplary embodiment shown is designed as a bridge rectifier. By means of the first rectifier circuit 14 , the single-phase alternating voltage at the supply voltage supply terminals 11 , 12 can be rectified. In order to reduce the ripple of the rectified voltage, a power factor correction circuit 16 is connected to the first rectification circuit 14, which has a first current path 17 and a second current path 18 connected in parallel with the first current path, between the two Connected in each current path is a diode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com