Chemical mixing and supplying system of coating machine

A coating machine and medicine supply technology, applied in the direction of seed coating/seed dressing, etc., can solve the problems such as equipment can not achieve fully enclosed operation, personal poisoning, environmental pollution, etc., achieve high qualification rate, high automation level, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

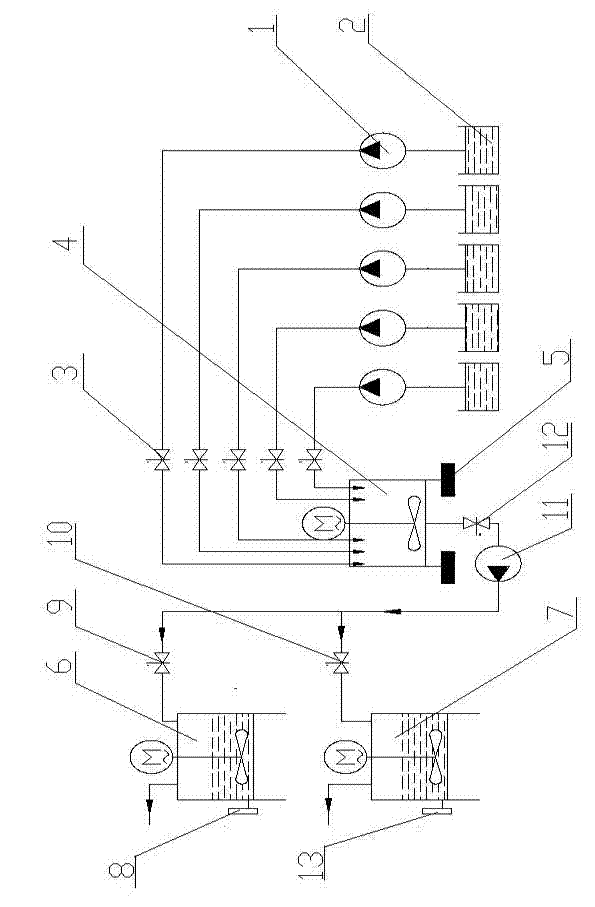

[0015] Such as figure 1 As shown, a drug mixing system for a coating machine includes a first peristaltic pump 1, a raw material cylinder 2, a first electric ball valve 3, a mixing cylinder 4, a load cell 5, a drug supply cylinder 6, and a spare drug supply cylinder 7 , the first membrane pressure sensor 8 , the second electric ball valve 9 , the third electric ball valve 10 , the second peristaltic pump 11 , the fourth electric ball valve 12 , and the second membrane pressure sensor 13 . The number of raw material cylinders 2 is five, and different kinds of coating agents are housed in each raw material cylinder 2 . The five communication pipelines on the five raw material cylinders 2 are respectively communicated with the mixing cylinder 4, and each communication pipeline is provided with a first peristaltic pump 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com