Method for extracting active ingredients from coreopsis tinctoria by subcritical water

A technology of active ingredients and subcritical water, applied in solid solvent extraction and other directions, can solve the problems that active ingredients cannot be fully extracted and utilized, and the extraction rate is low, and achieves the effect of maintaining natural quality, high extraction efficiency and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

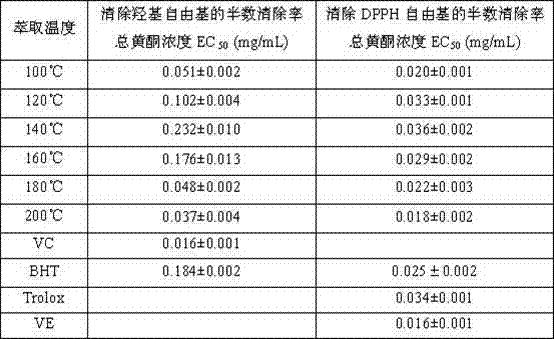

Examples

Embodiment 1

[0027] After pulverizing 2g of Xinjiang snow chrysanthemum, place it in a 100mL extraction kettle of subcritical fluid extraction process, first add 10mL of distilled water to soak for 5min, and stir to make the snow chrysanthemum powder completely wet by water, then add 40mL of distilled water, seal the extraction kettle, and make The extraction temperature was raised to 120°C within 5 minutes, and the extraction was carried out for 15 minutes; the temperature of the extraction kettle was quickly lowered to below 50°C, the extraction kettle was opened, and the filtrate was collected by filtration; The temperature was raised to 150°C within 5 minutes, extracted for 15 minutes, filtered, and the filter residue was washed with a small amount of hot water, the filtrate was combined, and the filtrate was concentrated under reduced pressure to obtain 0.95 g of chrysanthemum extract with a total flavonoid content of 28.7%.

Embodiment 2

[0029] Weigh 5g of pulverized Xinjiang snow chrysanthemum samples and place them in a 100mL subcritical fluid extraction extraction kettle, add 20mL distilled water to soak for 5min, stir to make the snow chrysanthemum powder completely wet by water, then add 30mL distilled water, seal the extraction kettle, and make the extraction The temperature was raised to 100°C within 5 minutes, extracted for 1 hour, and the extraction kettle was quickly cooled to room temperature, filtered, and the filter residue was put into the extraction kettle and 40 mL of distilled water was added, and then extracted for 0.5 hours; cooled and filtered, the filtrates were combined twice, and concentrated to obtain 1.35 g snow chrysanthemum extract, in which the total flavonoid content of snow chrysanthemum is 41.6%.

Embodiment 3

[0031] Weigh 5g of pulverized Xinjiang snow chrysanthemum samples and place them in a 100mL subcritical fluid extraction extraction kettle, add 20mL distilled water to soak for 5min, stir to make the snow chrysanthemum powder completely wet by water, then add 30mL distilled water, seal the extraction kettle, and make the extraction The temperature was raised to 140°C within 5 minutes, extracted for 1 hour, and the extraction kettle was quickly cooled to room temperature, filtered, and the filter residue was put into the extraction kettle and 40 mL of distilled water was added, and the above conditions were repeated for another 0.5 hours; cooled and filtered, the filtrates were combined twice, and concentrated Obtain 1.85g snow chrysanthemum extract afterward, wherein the total flavonoid content of snow chrysanthemum is 32.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com