Casting process for square shell of buffer of high-speed railway vehicle

A technology of high-speed railway and casting technology, which is applied in the field of metal casting, and can solve the problems that the quality and technical requirements of the buffer square box parts cannot be met.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

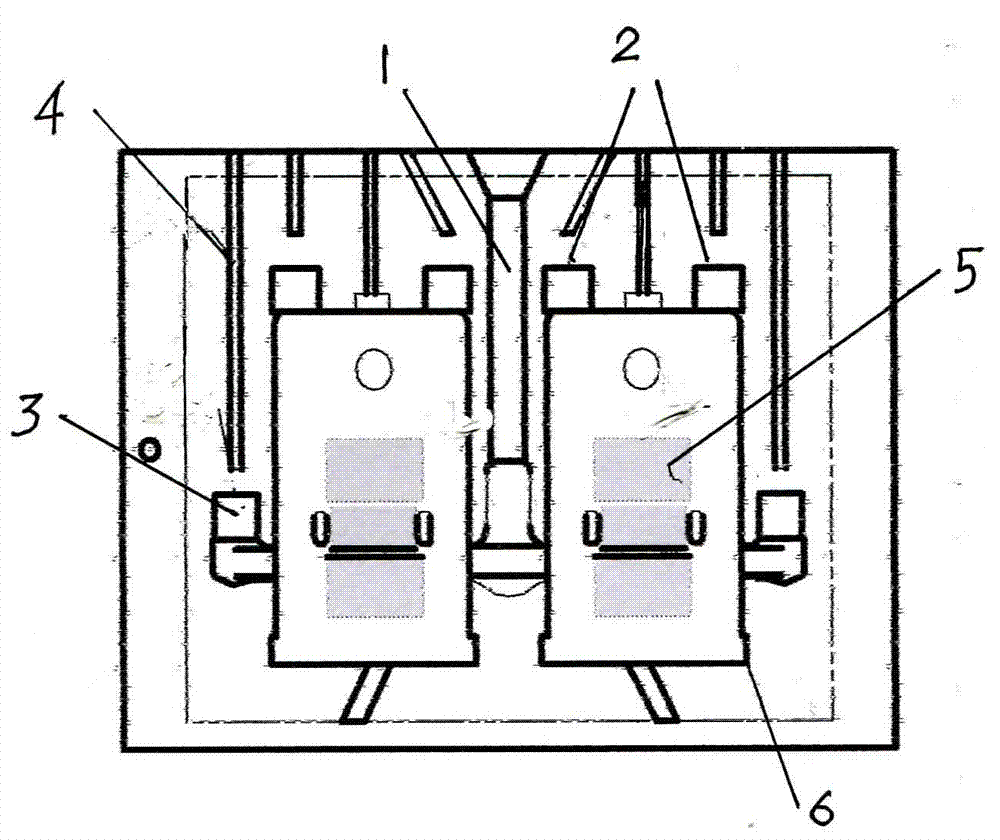

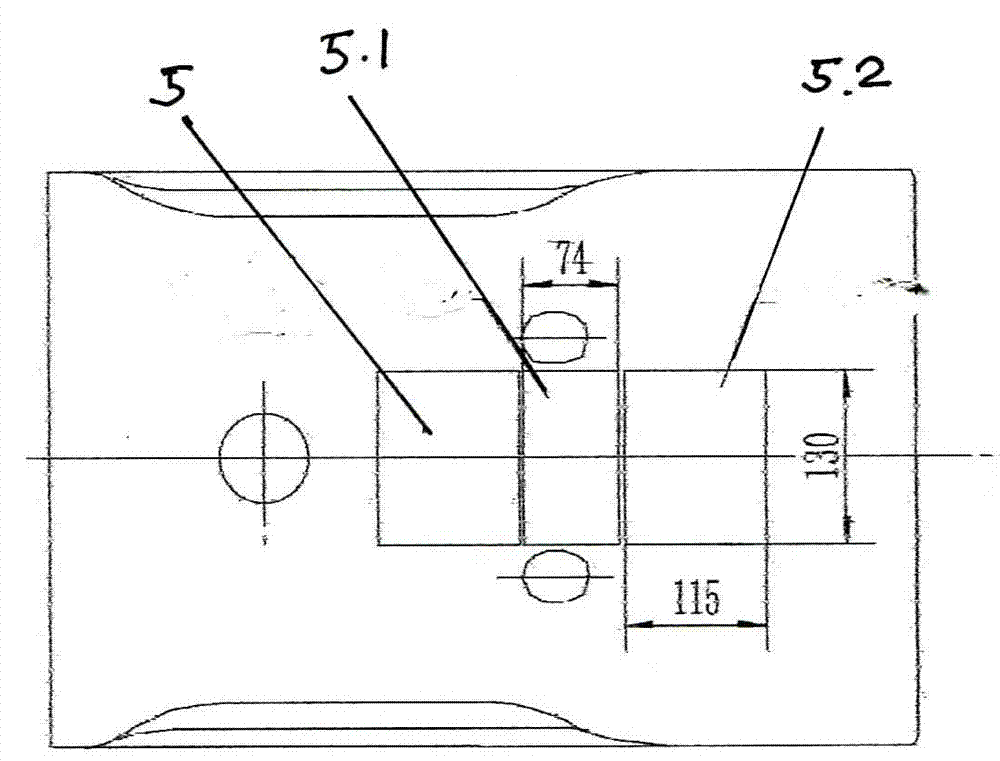

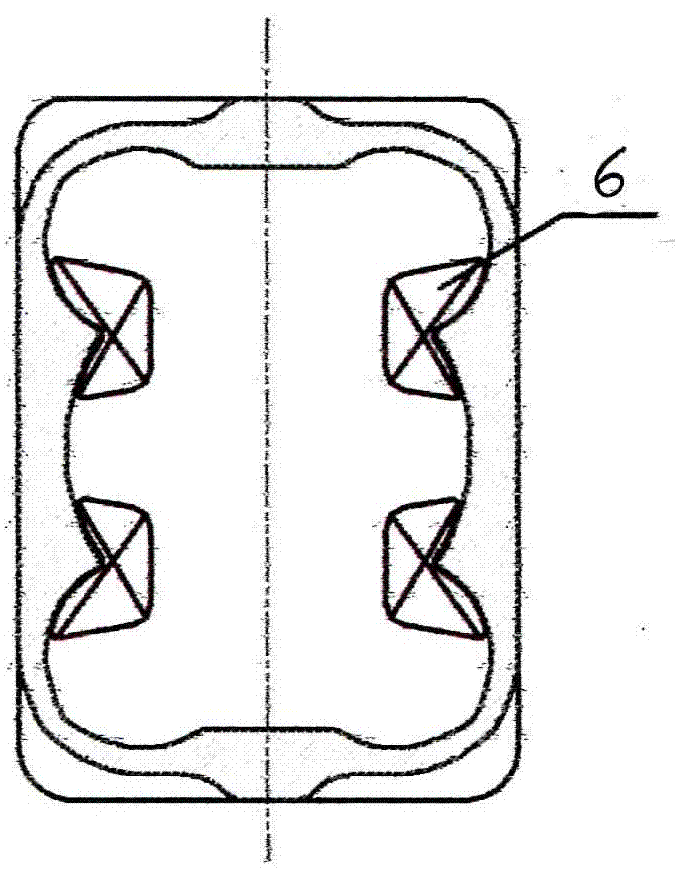

[0031] Process method of the present invention:

[0032] A high-speed railway vehicle buffer square box casting process method,

[0033] 1. Shell core

[0034] Phenolic resin-coated sand has high strength, long storage time, and is not easy to pulverize, which is beneficial to ensure the dimensional accuracy of castings and prevent the occurrence of sand holes in castings. Rinsing paint can also improve the surface finish of castings. At present, it is a relatively advanced modeling core making square hair in China. K87 core shooter for core making, with high production efficiency and reliable performance. After the core is made, it is bonded with quick gel, rinsed with paint, and dried in an electric kiln at 180-200°C for 1-2 hours before use.

[0035] 2. Shape

[0036] The sand mold of the outer shell of the square box adopts the process of carbon dioxide blowing Ecolotec650 resin surface and back sand. First add Ecolotec650 resin sand to the sand box and compact it. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com