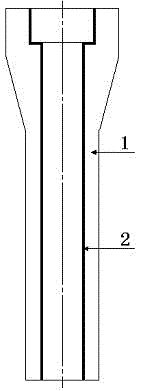

A long nozzle lining material without preheating composite structure

A composite structure, no preheating technology, applied in the direction of casting melt containers, manufacturing tools, metal processing equipment, etc., can solve the problems of cumbersome process and difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The ingredients of a composite structure long nozzle lining material are 20wt% fused white corundum; 38wt% fused zirconia mullite; 24wt% fused silica; 12wt% light-burned alumina; 6wt% zinc oxide; the binder is phenolic resin , and its addition is 8% of the total weight of the lining material.

Embodiment 2

[0028] The ingredients of a long nozzle lining material with a composite structure are 20wt% fused white corundum; 37wt% fused zirconia mullite; 24wt% fused silica; 11wt% lightly burned alumina; 8wt% zinc oxide; the binder is phenolic resin , and its addition is 8% of the total weight of the lining material.

Embodiment 3

[0030] The ingredients of a long nozzle lining material with a composite structure are 20wt% fused white corundum; 35wt% fused zirconia mullite; 24wt% fused silica; 11wt% lightly burned alumina; 10wt% zinc oxide; the binder is phenolic resin , and its addition is 8% of the total weight of the lining material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com