Stop mechanism for transfer gripper in offset press

A technology of stopper mechanism and paper feeding teeth, applied in the general parts of printing machinery, printing presses, printing and other directions, can solve the problems affecting the service life of the swing arm 13 and the swing rod cam 6, the impact vibration of the swing rod cam-spring system, the paper Problems such as adverse effects of handover and transfer, to achieve the effect of being conducive to smooth handover, avoiding shock and vibration, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better understand the technical solutions of the present invention, specific embodiments will be described in detail below in conjunction with the accompanying drawings.

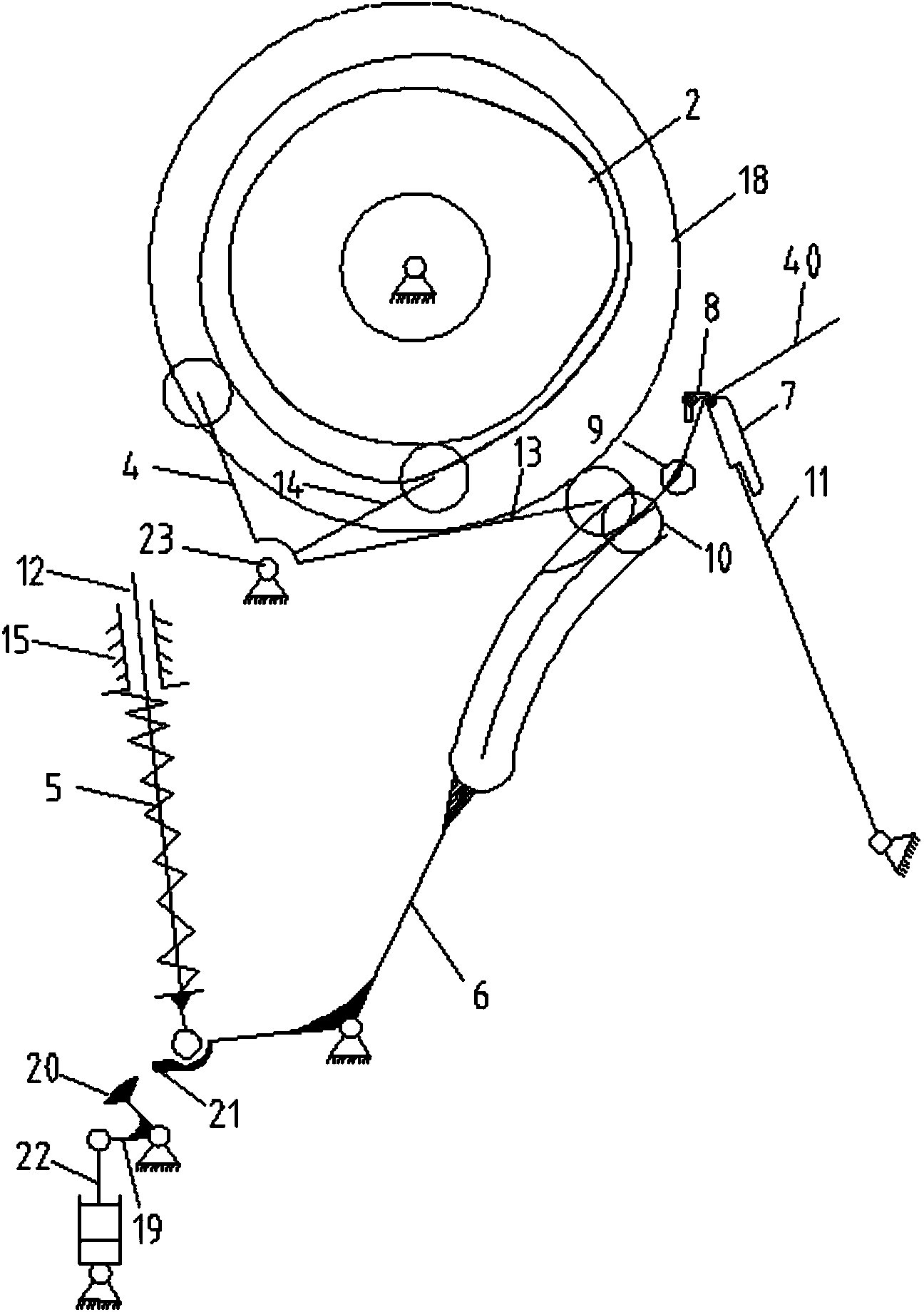

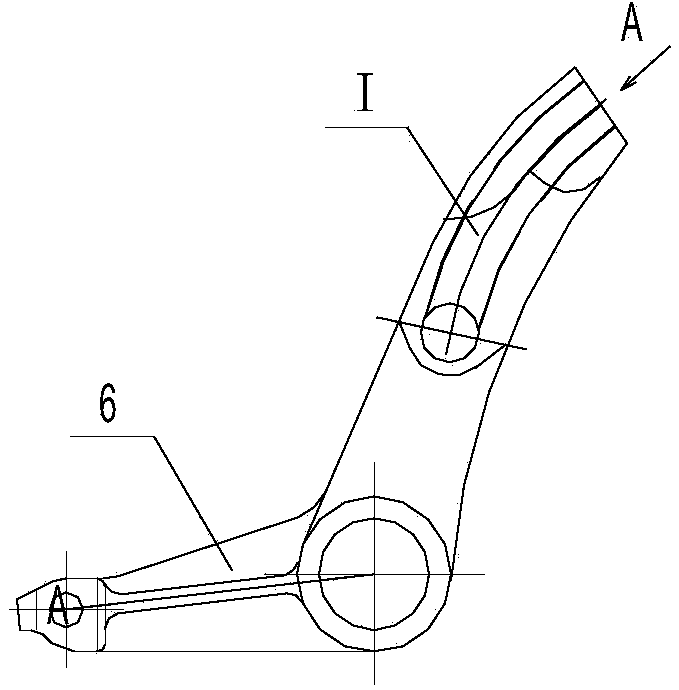

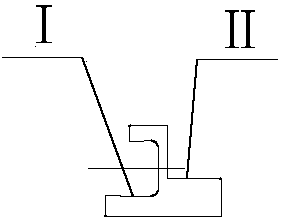

[0038] see Figure 3 to Figure 5c , a stop mechanism for the paper delivery teeth of an offset printing press of the present invention, including a paper delivery cylinder 26 bridged between the driving side wallboard 29 and the operation side wallboard of the offset printing machine, a paper delivery hand, and a teeth opening and closing mechanism and protection agencies.

[0039] The transfer cylinder 26 is bridged between the driving side wallboard 29 and the operating sidewallboard of the offset printing machine; a cover-type support frame 30 is installed on the outside of the driving sidewallboard 29; Shaped bracket 28; the driving side shaft head of the paper transfer cylinder 26 passes through the driving side wall plate 29 and is installed on the bottom plate of the support frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com