Fully welded air suspension coupling structure

An air suspension, all-welded technology, applied in suspension, elastic suspension, cantilever mounted on the pivot, etc., can solve the problems of easy bolt loosening, low economic benefits, failure, etc., to reduce the complexity of processing technology , Eliminate potential safety hazards and reduce the effect of manufacturing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

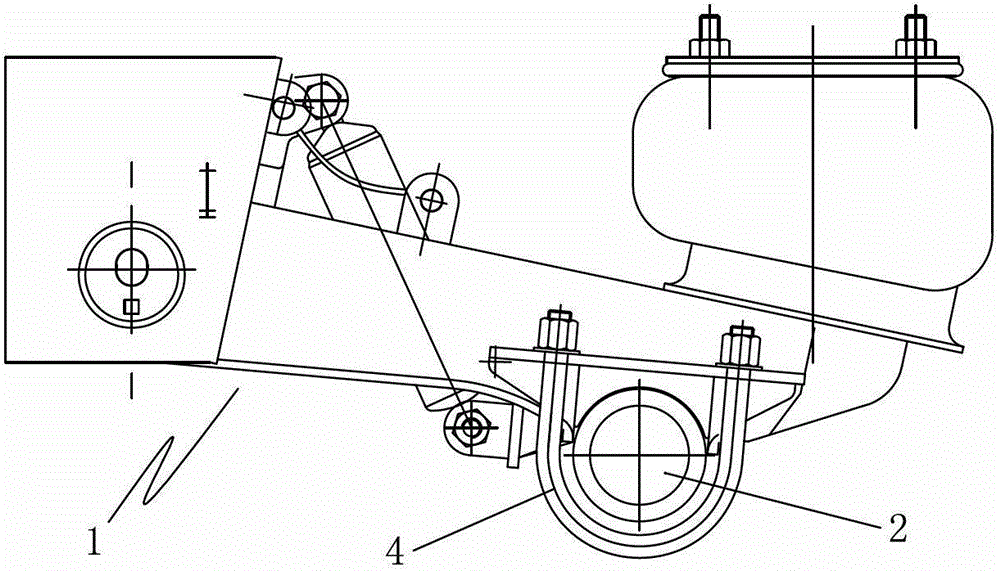

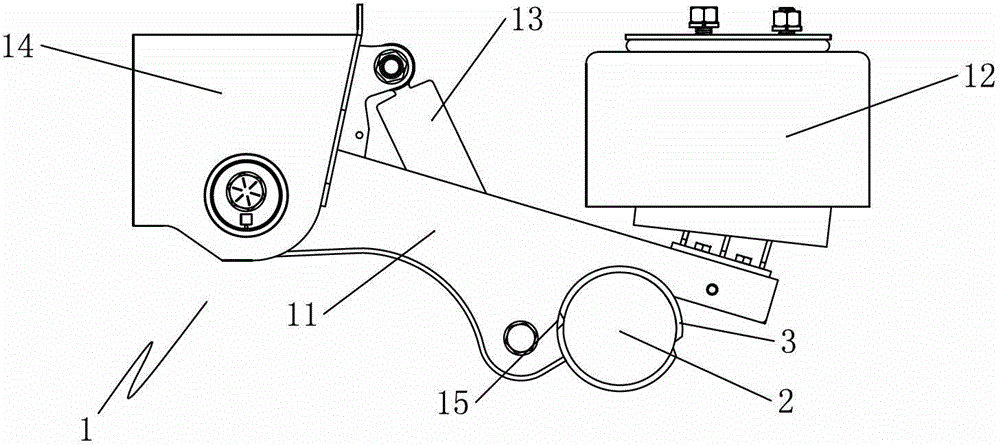

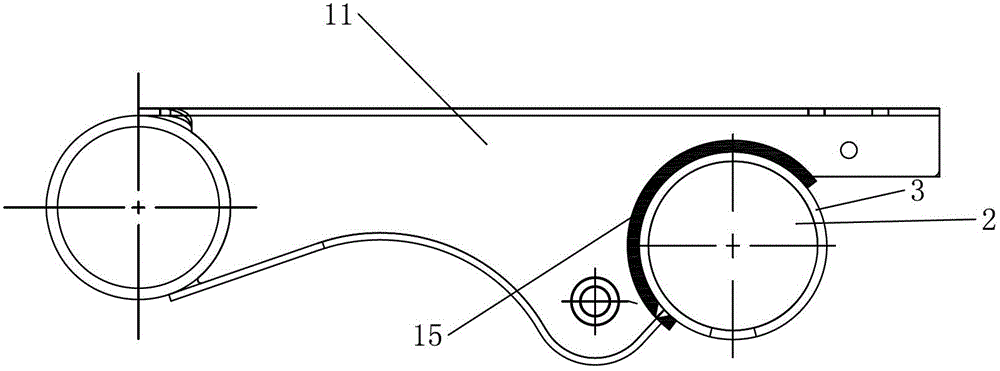

[0021] like Figures 2 to 5 As shown, the fully welded air suspension coupling structure of the present invention includes a suspension assembly 1 and an axle 2. The suspension assembly 1 includes a main beam 11, an air spring 12, a shock absorber 13 and a front bracket 14. The specific structure as follows:

[0022] The main beam 11 is inwardly recessed to form an open arched axle seat 15 for installing the axle, and the outline of the installation part of the open arched axle seat 15 is in the shape of a inferior arc. Further, the open arched axle The contour of the installation part of the seat 15 is a minor arc shape greater than 120° and less than 180°, wherein, as a preferred embodiment, the contour of the installation part of the open arched shaft seat 15 is a minor arc shape of 170°, due to the open The profile of the installation part of the arched axle seat 15 is less than 180° semicircle. On the one hand, it reduces the material used for the main beam 11. On the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com