Mildronate dihydrate preparation method

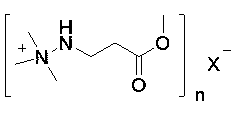

A technology of meldonium dihydrate and meldonium, which is applied in hydrazine preparation, organic chemistry and other directions, can solve the problems of high pH, high burning residue, incomplete removal of chlorides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

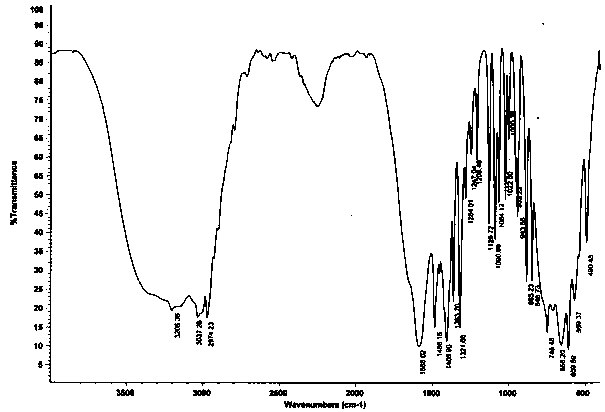

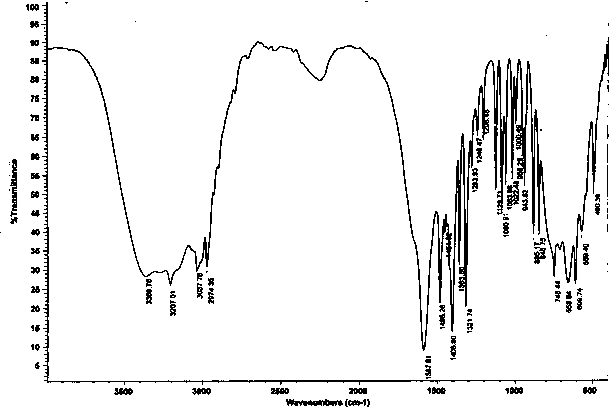

Image

Examples

Embodiment 1

[0035]Preparation of aqueous solution after alkaline hydrolysis: Take 3000 grams of strong basic anion resin, put it into a resin column of appropriate size, activate it according to the treatment method of resin, and heat it up to 40°C-45°C for later use. Take 100 grams of 3-(2,2,2-trimethylhydrazino) methyl propionate sulfate and add it to 1000 grams of purified water, mix well, and heat up to 35°C-40°C. Then the aqueous solution is passed through the prepared column that 3000 grams of strong basic anion resin is housed, and the column liquid is circulated through the column until the HPLC detects that the alkaline hydrolysis reaction is complete, and the column liquid is collected. Rinse the resin column with 1000 g of purified water to rinse the material attached to the resin. The combined column liquids were concentrated under reduced pressure in a flask to a volume of 50ml-100ml to obtain an aqueous solution after alkali hydrolysis.

[0036] Preparation of meldonium aqu...

Embodiment 2

[0040] Preparation of aqueous solution after alkaline hydrolysis: Take 1500 grams of strong basic anion resin, put it into a resin column of suitable size, activate it according to the treatment method of resin, and heat it up to 40°C-45°C for later use. Take 50 grams of chloride salt of methyl 3-(2,2,2-trimethylhydrazino)propionate and add it to 500 grams of purified water, mix well, and heat up to 40°C-45°C. Then the aqueous solution is passed through the prepared column that 1500 grams of strong basic anion resin is housed, and the column liquid is circulated through the column until the HPLC detects that the alkaline hydrolysis reaction is complete, and the column liquid is collected. Rinse the resin column with 500 grams of purified water to rinse the material attached to the resin. The combined column liquids were concentrated under reduced pressure in a flask to a volume of 75ml-100ml to obtain an aqueous solution after alkali hydrolysis.

[0041] Preparation of meldon...

Embodiment 3

[0045] Preparation of aqueous solution after alkaline hydrolysis: Take 12,500 grams of strong basic anion resin, put it into a resin column with a suitable size, activate it according to the resin treatment method, and heat it up to 40°C-45°C for later use. Take 500 g of 3-(2,2,2-trimethylhydrazino) methyl propionate sulfate and add it to 7500 g of purified water, mix evenly, and heat up to 45°C-50°C. Then the aqueous solution is passed through the prepared column that 12500 grams of strong basic anion resin is housed, and the column liquid is circulated through the column until the HPLC detects that the alkaline hydrolysis reaction is complete, and the column liquid is collected. Rinse the resin column with 7500 grams of purified water to rinse the material attached to the resin. The combined column liquids were concentrated under reduced pressure in a flask to a volume of 1000-1500 ml to obtain an aqueous solution after alkali hydrolysis.

[0046] Preparation of meldonium a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com