High-acrylonitrile NBR/PVC (nitrile-butadiene rubber/polyvinyl chloride) oil-resistant ozone-resistant rubber material and preparation method thereof

A rubber material, acrylonitrile technology, applied in the field of rubber materials and its preparation, can solve the problems of little research on NBR/PVC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The NBR / PVC oil-resistant and ozone-resistant rubber material with high acrylonitrile content described in this embodiment is composed of NBR, PVC, filling reinforcing agent, plasticizer, anti-aging agent, vulcanizing agent, stabilizer and other rubber processing aids .

[0024] This example includes 70 parts of NBR, 30 parts of PVC, 2.0 parts of stabilizer, 20 parts of DOP, 25 parts of 3G8, 30 parts of N550, 30 parts of N774, 1.5 parts of 4010NA, 1.5 parts of RD, 2.5 parts of sulfur, 1.5 parts of CZ, 2.0 parts Part paraffin, 5.0 parts zinc oxide, 1.5 parts stearic acid.

[0025] The preparation method of the NBR / PVC oil-resistant and ozone-resistant rubber material with high acrylonitrile content of the present invention is a mechanical blending method, and the specific steps are as follows:

[0026] (1) NBR / PVC blending: Pre-plasticize PVC, plasticizers, stabilizers, etc. in a high-speed mixing mixer, masticate evenly in a double-roller open mill (130~140°C), and...

Embodiment 2

[0033] The composition of this example is basically the same as that of Example 1, except that 1.5 parts of sulfur, 1.2 parts of CZ, and 0.3 parts of TMTD are used instead of 2.5 parts of sulfur and 1.5 parts of CZ.

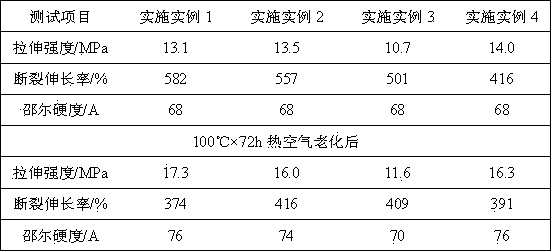

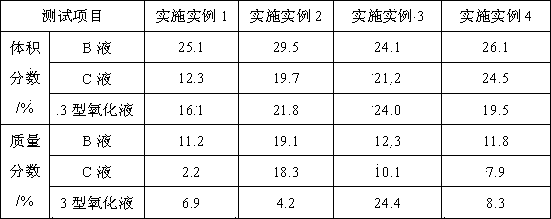

[0034] The mechanical performance test results of the NBR / PVC oil-resistant and ozone-resistant rubber material with high acrylonitrile content obtained in this example are shown in Table 1, the oil resistance test results are shown in Table 3, and the ozone aging resistance results are shown in Table 5.

Embodiment 3

[0036] The composition of this example is basically the same as that of Example 1, except that 0.5 parts of sulfur, 1.0 part of CZ, and 0.5 parts of TMTD are used instead of 2.5 parts of sulfur and 1.5 parts of CZ.

[0037]The mechanical performance test results of the NBR / PVC oil-resistant and ozone-resistant rubber material with high acrylonitrile content obtained in this example are shown in Table 1, the oil resistance test results are shown in Table 3, and the ozone aging resistance results are shown in Table 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com