A kind of PE bright varnish and preparation method thereof

A gloss and varnish technology, applied in the field of coatings, can solve the problems of poor coating effect, not high enough, prone to pinhole gloss, etc., to achieve the elimination of pinhole phenomenon on the board surface, wide miscibility, and improve product gloss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the PE gloss varnish described in the embodiment of the present invention can be prepared by the following method, of course, it can also be prepared by other methods that can prepare the PE gloss varnish.

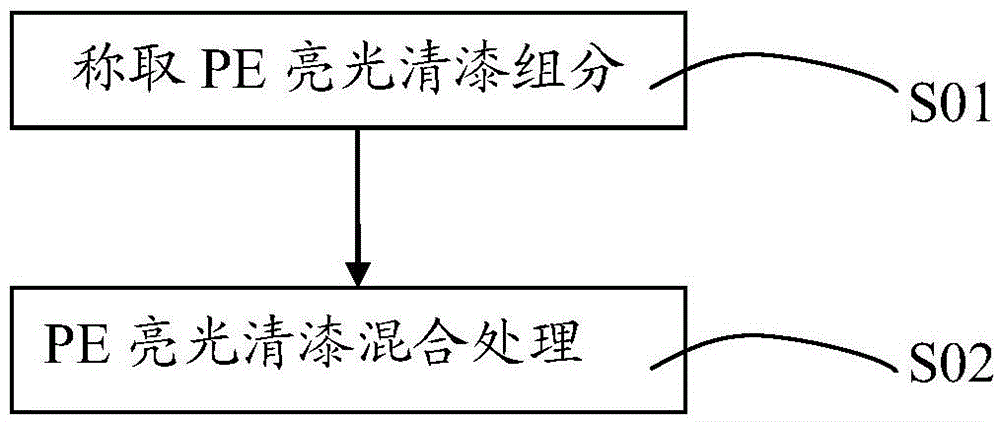

[0029] Correspondingly, the embodiment of the present invention also provides a preparation method of PE glossy varnish, including the following steps, as shown in the attached figure 1 Shown:

[0030] S01. Weighing PE gloss varnish components: weigh each component according to the above PE gloss varnish formula;

[0031]S02. PE gloss varnish mixing treatment: mix PE resin, synthetic fatty acid resin, and polymerization inhibitor at 200-500 rpm for 3-10 minutes at low speed; add leveling agent, defoamer, anti-greening agent, 800-1200 rpm Mix at high speed for 15-25 minutes; then add solvent and mix at medium speed at 550-750 rpm for 3-10 minutes.

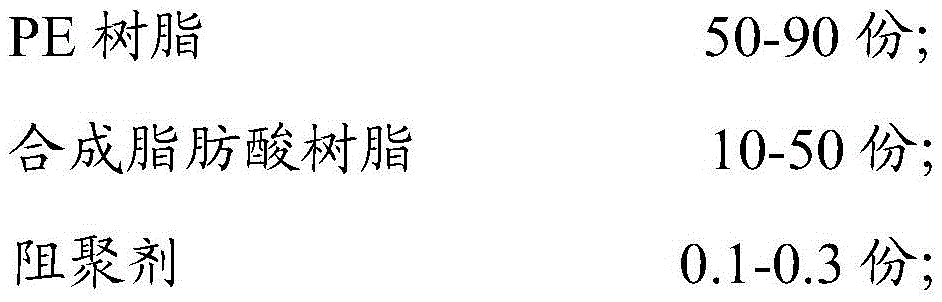

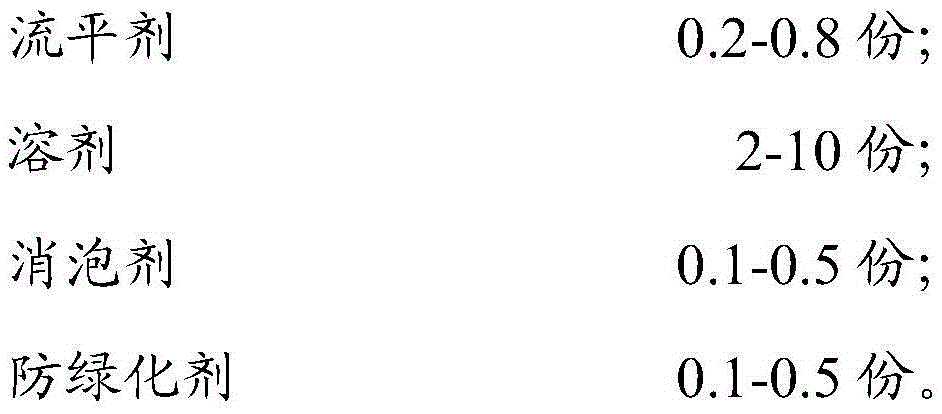

[0032] Specifically, in the above step S01, the formulation of the PE gloss varnish and the...

Embodiment 1

[0037] A kind of PE gloss varnish, the formula component that it comprises and the content of corresponding component are shown in embodiment 1 in the following table 1.

[0038] Preparation method of PE glossy varnish:

[0039] (1) Weigh each component according to the formula of Example 1 in Table 1;

[0040] (2) Mix PE resin, synthetic fatty acid resin, and polymerization inhibitor, mix at a low speed of 400 rpm for 5 minutes; add leveling agent, defoamer, anti-greening agent, and mix at a high speed of 1000 rpm for 20 minutes; then add solvent , 700 rev / min medium speed mixing for 5 minutes; mixing process.

Embodiment 2

[0042] A kind of PE gloss varnish, the formula component that it comprises and the content of corresponding component are shown in embodiment 2 in the following table 1.

[0043] Preparation method of PE glossy varnish:

[0044] (1) Weigh each component according to the formula of Example 2 in Table 1;

[0045] (2) Mix PE resin, synthetic fatty acid resin, and polymerization inhibitor, mix at a low speed of 300 rpm for 8 minutes; add leveling agent, defoamer, anti-greening agent, and mix at a high speed of 1200 rpm for 15 minutes; then add solvent , 600 rev / min medium speed mixing for 3 minutes; mixing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com