Thermoplastic-elastomer-containing complex aluminum-based lubricating grease composition and preparation method thereof

A thermoplastic elastomer and grease composition technology, which is applied in lubricating compositions, petroleum industry, etc., can solve the problems of reduced base oil adsorption capacity, reduced colloidal structure stability, thinning and softening of complex aluminum soap, etc. Efficacy of high temperature bleed, improved stability, improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

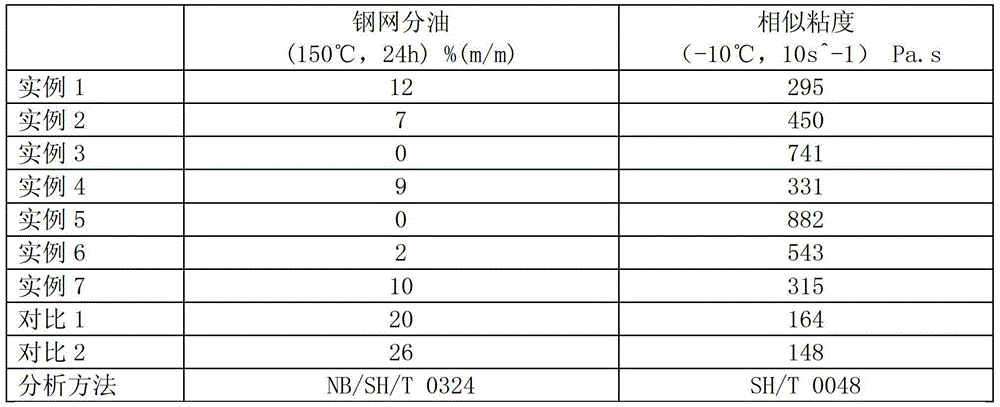

[0029] Add 150BS (ν 100 =34.17) 500g and 500SN (ν 100 =12.18) 520g, add 15g of benzoic acid and 35g of stearic acid, mix and stir evenly, when the reaction temperature is 90-92°C, add 18g of aluminum isopropoxide trimer (purity 70%) and react for 60 minutes, add thermoplastic elastomer lubrizol 7306 14g, when the temperature rises to 110-112°C, stir at a constant temperature for 60 minutes, continue to heat up to 218-220°C, keep the temperature at a constant temperature for 10 minutes, add 500SN (ν 100 =12.18) 255g, then lowered to room temperature, and finally ground into fat with a three-roll machine. Performance see Table 1

Embodiment 2

[0031] Add 500SN (ν 100 =11.18) 650g and 150BS (ν 100 =33.92) 415g, add 16g of benzoic acid and 37g of stearic acid, mix and stir evenly, add 19g of aluminum isopropoxide trimer (purity 70%) when the reaction temperature is 94-96°C, react for 60 minutes, add thermoplastic elastomer lubrizol 7306 43g, when the temperature rises to 118-120°C, stir at a constant temperature for 60 minutes, continue to heat up to 200-202°C, keep the temperature at a constant temperature for 10 minutes, add 150BS (ν 100 =33.92) 266g, then lowered to room temperature, and finally ground into fat with a three-roll machine. Performance see table 1

Embodiment 3

[0033] Add 150BS (ν 100 =35.21) 450g and 500SN (ν 100 =10.88) 462g, add 14g of benzoic acid and 33g of stearic acid, mix and stir evenly, add 17g of aluminum isopropoxide trimer (purity 70%) when the reaction temperature is 98-100℃, react for 60 minutes, add thermoplastic elastomer lubrizol 7306 63g, when the temperature rises to 114-116°C, stir at a constant temperature for 60 minutes, continue to heat up to 190-192°C, keep the temperature at a constant temperature for 10 minutes, add 500SN (ν 100 =10.88) 228g, then lowered to room temperature, and finally ground into fat with a three-roll machine. Performance see table 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com