High-temperature polyurea lubricating grease composition and preparation method thereof

A kind of grease composition, the technology of the composition, applied in the field of grease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

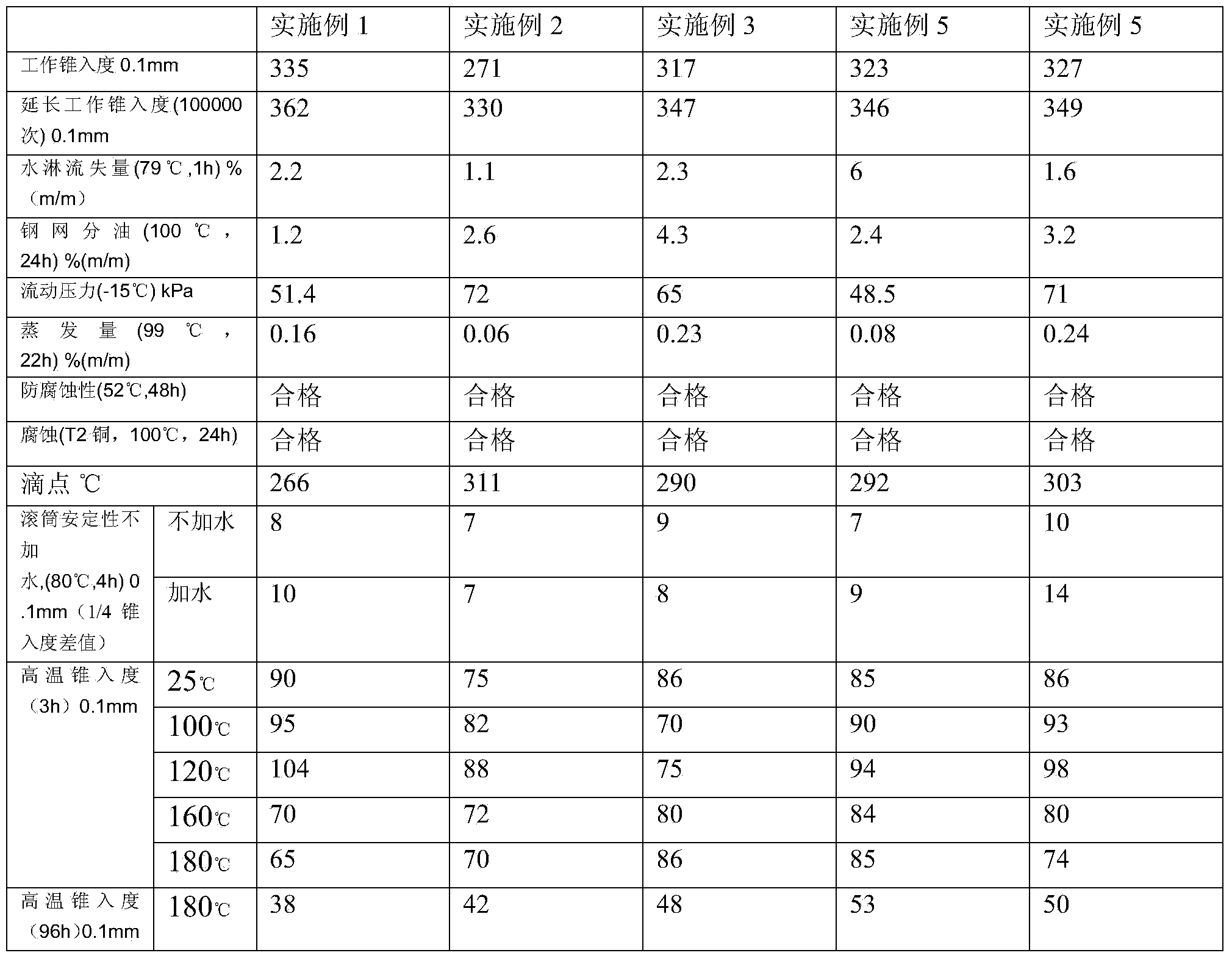

Examples

Embodiment 1

[0035] Add 400g of PAO40 and 1200g of HVI650 base oil into the reaction kettle, add 50g of diphenylmethane diisocyanate, and raise the temperature. The temperature in the kettle is raised to 80°C, add 16g of aniline, 16g of cyclohexylamine, and 20g of octadecylamine, keep the temperature at 100°C and stir for 60 minutes at a constant temperature; ℃, add 200g of HVI650 base oil into the reaction kettle for cooling, the cooling temperature is controlled at 150-170 ℃, the temperature is naturally lowered, and the consistency is adjusted; T706: 1g, T531: 2g, stirred at constant temperature for 30 minutes, oiled three times in a three-roll mill, and then packed in cans.

Embodiment 2

[0037] Add 1200g of PAO40 and 500g of HVI650 base oil into the reaction kettle, add 137g of diphenylmethane diisocyanate, and raise the temperature. The temperature in the kettle rises to 60°C, add 21g of aniline and 81g of cyclohexylamine, and keep the temperature at 100°C for constant temperature reaction for 60 minutes; after the reaction is completed, add 50g of aluminum isopropoxide, raise the temperature, the maximum temperature is 180°C, cool down naturally, and adjust the consistency; If appropriate, cool down to 60-90°C and add T705: 20g, Siben-80: 20g, T706: 20g, T531: 40g, stir at a constant temperature for 30min, press oil three times with a three-roller machine, and then pack in cans.

Embodiment 3

[0039] Add 900g of 150BS and 950g of PAO100 base oil into the reaction kettle, add 200g of diphenylmethane diisocyanate, and raise the temperature. The temperature in the kettle is raised to 80°C, add 215g of octadecylamine and 80g of dodecanediamine, keep the temperature at 100°C and stir for 60 minutes; after the reaction is completed, add 100g of pentaerythritol and raise the temperature until the maximum temperature reaches 190°C, then cool down naturally and adjust the consistency If the consistency is right, cool down to 60-90°C and add T705: 10g, Benzene-80: 2g, T706: 0.4g, antioxidant T531: 80g, stir at constant temperature for 30min, and then pack in cans after three times of three-roller oil pressing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com