Chemical modified fiber type immobilization carrier as well as preparation method and application thereof

An immobilized carrier and chemical modification technology, applied in the direction of biochemical equipment and methods, fixed on/in organic carriers, specific-purpose bioreactors/fermenters, etc., can solve the problem of long butanol fermentation cycle, Butanol needs to be improved and the production rate is low to achieve the effect of improving immobilization efficiency, cell immobilization efficiency and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

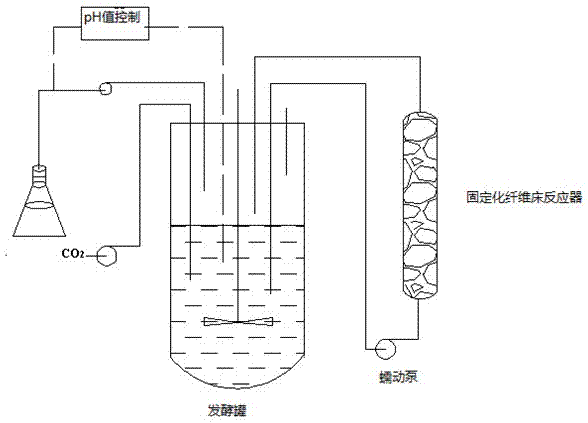

Image

Examples

Embodiment 1

[0041] This example is to demonstrate the application of modified bagasse as an immobilized carrier in single-batch fermentation of butanol.

[0042] Bacteria: Clostridium acetobutylicum Clostridium acetobutylicum XY16 (CCTCC NO: M 2010011)

[0043] Seed medium: Seed medium: yeast powder 3 g / L, peptone 5 g / L, soluble starch 10 g / L, ammonium acetate 2 g / L, NaCl 2 g / L, MgSO 4 3 g / L, KH 2 PO 4 1 g / L, K 2 HPO 4 1 g / L, FeSO 4 ·7H 2 O 0.1 g / L, pH 6.0;

[0044] Fermentation medium (P2): carbon source (glucose 60 g / L dissolved), K 2 HPO 4 0.5 g / L, KH 2 PO 4 0.5 g / L, CH3 COONH 4 2.2 g / L, MgSO 4 ·7H 2 O 0.2 g / L, MnSO 4 ·H 2 O 0.01 g / L, NaCl 0.01 g / L, FeSO 4 ·7H 2 O 0.01 g / L; corn steep liquor 1 g / L.

[0045] In this experiment, sugarcane bagasse was taken as an example to illustrate the specific steps of selecting the dosage of polyethyleneimine modifier.

[0046] The amount of bagasse added was 10 g / L (modified by 4 g / L polyethyleneimine and 1 g / L glutaralde...

Embodiment 2

[0048] This example is to demonstrate the application of modified corn stalks as an immobilized carrier in single-batch fermentation of butanol.

[0049] Bacteria: Clostridium acetobutylicum Clostridium acetobutylicum XY16 (CCTCC NO: M 2010011)

[0050] Seed medium: Seed medium: yeast powder 3 g / L, peptone 5 g / L, soluble starch 10 g / L, ammonium acetate 2 g / L, NaCl 2 g / L, MgSO 4 3 g / L, KH 2 PO 4 1 g / L, K 2 HPO 4 1 g / L, FeSO 4 ·7H 2 O 0.1 g / L, pH 6.0;

[0051] Fermentation medium (P2): carbon source (glucose 60 g / L dissolved), K 2 HPO 4 0.5 g / L, KH 2 PO 4 0.5 g / L, CH 3 COONH 4 2.2 g / L, MgSO 4 ·7H 2 O 0.2 g / L, MnSO 4 ·H 2 O 0.01 g / L, NaCl 0.01 g / L, FeSO 4 ·7H 2 O 0.01 g / L; corn steep liquor 1 g / L.

[0052] In this experiment, corn stalks were taken as an example to illustrate the specific steps of selecting the dosage of polyethyleneimine modifier.

[0053] The addition amount of corn straw was 10 g / L (modified by 4 g / L polyethyleneimine and 1 g / L glu...

Embodiment 3

[0055] This example is to demonstrate the application of modified rice straw as an immobilized carrier in butanol fermentation.

[0056] Bacteria: Clostridium acetobutylicum Clostridium acetobutylicum AS1.135 (CGMCC 1.135)

[0057] Seed medium: Seed medium: yeast powder 3 g / L, peptone 5 g / L, soluble starch 10 g / L, ammonium acetate 2 g / L, NaCl 2 g / L, MgSO 4 3 g / L, KH 2 PO 4 1 g / L, K 2 HPO 4 1 g / L, FeSO 4 ·7H 2 O 0.1 g / L, pH 6.0;

[0058] Fermentation medium (P2): carbon source (glucose 60 g / L dissolved), K 2 HPO 4 0.5 g / L, KH 2 PO 4 0.5 g / L, CH 3 COONH 4 2.2 g / L, MgSO 4 ·7H 2 O 0.2 g / L, MnSO 4 ·H 2 O 0.01 g / L, NaCl 0.01 g / L, FeSO 4 ·7H 2 O 0.01 g / L; corn steep liquor 1 g / L.

[0059] In this experiment, rice straw was taken as an example to illustrate the specific steps of selecting the dosage of polyethyleneimine modifier.

[0060] The addition amount of rice straw was 10 g / L (modified by 4 g / L polyethyleneimine and 1 g / L glutaraldehyde, the ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com