Preparation method for novel warp knitting Jacquard sport suit fabric

A sportswear fabric and new technology, applied in the field of clothing production, can solve the problems of single organizational structure, complex material preparation process, unreasonable production process arrangement, etc., and achieve the effects of advanced technology, simple preparation and excellent moisture absorption and perspiration function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

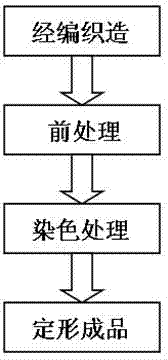

[0019] The specific preparation method is as follows:

[0020] a) Warp knitting, warp knitting includes the following steps: 1) Selection of raw materials and equipment; the raw material is Lucool special-shaped fiber polyester yarn with a linear density of 8.3tex / 72f, and the special-shaped fiber polyester yarn has a multi-groove cross-section structure. The good hygroscopicity, air permeability and quick-drying properties are due to the fact that there are many internal and external grooves on the surface, which make it easier for water to enter the interior of the fiber. The transfer provides a channel, so that the moisture can be quickly transferred to the surface of the fabric and distributed through the functions of wicking, diffusion, and transmission; the equipment adopts Jacquard warp knitting machine, the machine number is 28 needles / 25.4mm, and the width is 330 cm. The number of combs is 2, and the machine speed is 1050r / min. 2) Design of weaving process parameters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com