Virtual reality technology based remote control system and remote control method for coal cutter

A virtual reality technology and control system technology, which is applied in the field of remote control system of coal mining machine, can solve the problems of complex space environment, difficulty of remote control, and many equipment, and achieve the effect of convenient implementation, novel and reasonable design, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

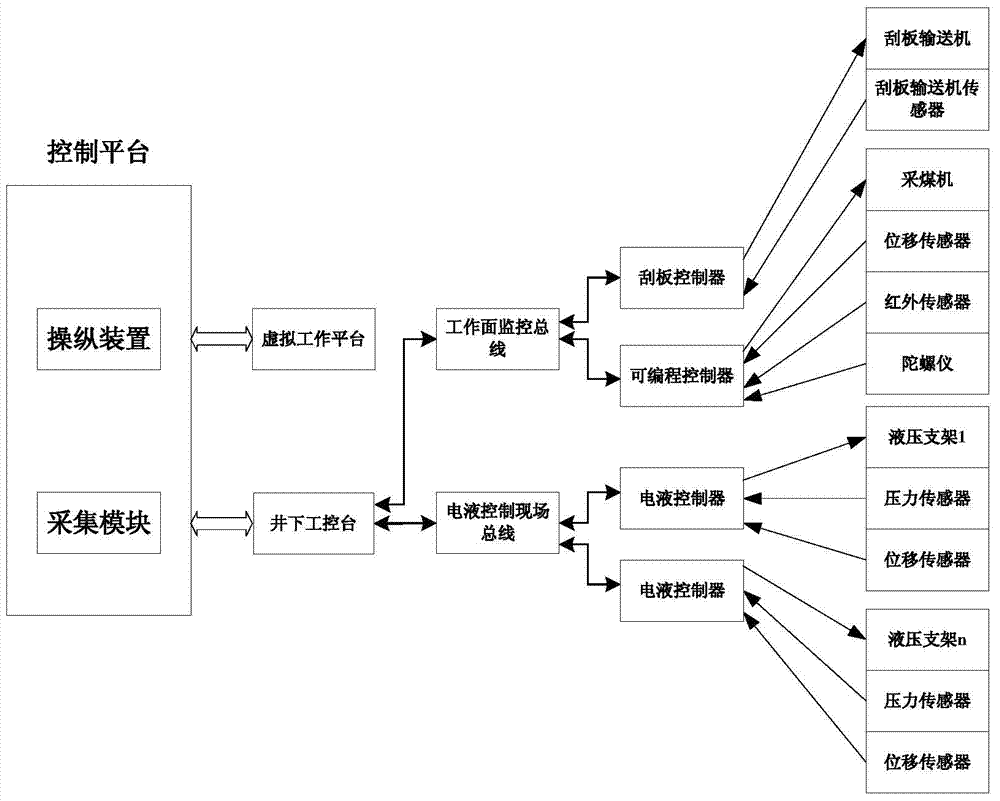

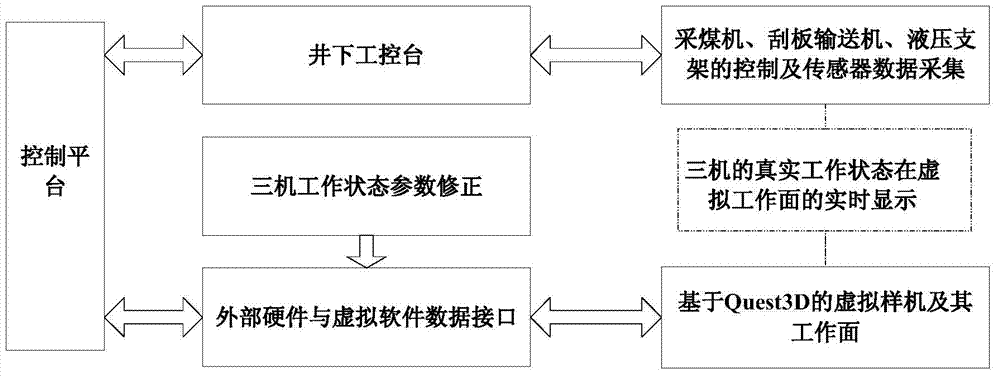

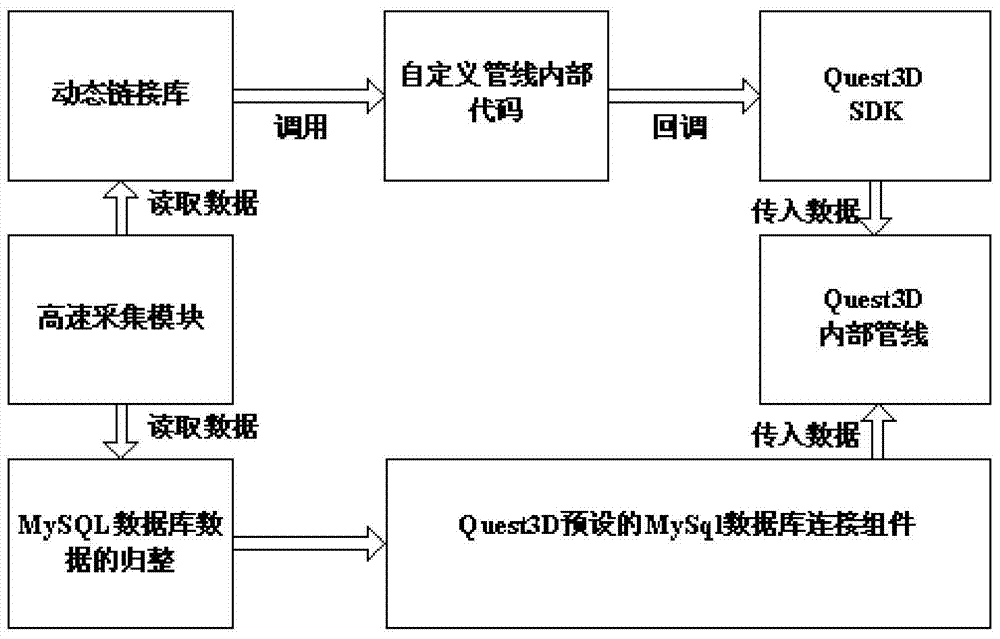

[0020] like figure 1 As shown, the working principle of the shearer control system based on virtual reality: first, the remote control device sends out control commands, which are received and driven by the underground industrial console to drive the three underground machines (shearer, scraper conveyor, hydraulic support, hereinafter referred to as " "Three machines") work, and collect and process the working status data of the three underground machines in real time, and upload them to the control platform by the data acquisition module; at the same time, the control commands issued by the remote control device are collected by the software and hardware data interface and sent to the virtual machine The working platform is driven by the program written in-house to complete the virtual device. In addition, the control platform also sends the working status data to the virtual equipment for correction in real time, realizing the synchronous operation of the three underground m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com