Automatic fuel adjustment system and method of multi-fuel fired boiler

An automatic adjustment and fuel technology, applied in the combustion method, adjustment of fuel supply, control of combustion, etc., can solve the problems of poor automatic adjustment of fuel quality, large heat loss, gas explosion, etc. The effect of channel time lag reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

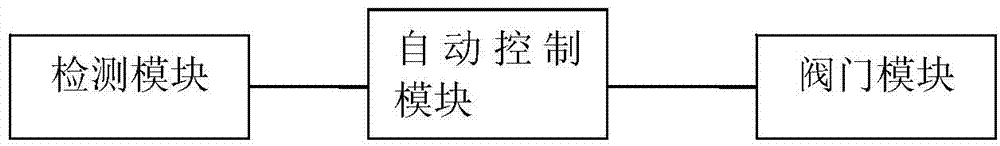

[0045] Before the co-fired boiler starts to work, first confirm that the regulators of each layer of the burner are in the automatic adjustment mode, and set the boiler superheated steam pressure setting value and deviation high limit. After the boiler burner is working, the detection module detects the measured value of the superheated steam pressure of the boiler and transmits the measured value to the automatic control module. The value is compared with the set deviation high limit value and deviation low limit value, if the deviation value is greater than or equal to the preset deviation high limit value, the fuel load increase regulation is started. The operation process of fuel load increase adjustment is as follows: First, the automatic control module controls the valve module to input fuel in sequence according to the order of coke oven gas, upper blast furnace gas, lower blast furnace gas, upper layer pulverized coal, middle layer pulverized coal, and lower layer pulve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com