A disk and ring type baffle plate floating head heat exchanger with temperature control function

A baffle, annular technology, used in the field of heat exchangers, can solve the problem that the outlet temperature cannot reach the design temperature, the heat exchanger cannot maintain steady-state operation, and the downstream equipment of the heat exchanger cannot maintain steady-state operation, etc. problems, to achieve the effect of reducing power costs, avoiding damage, and reducing the possibility of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

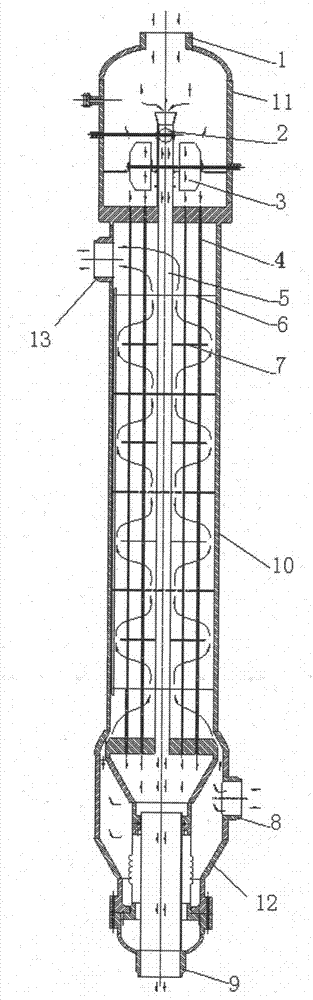

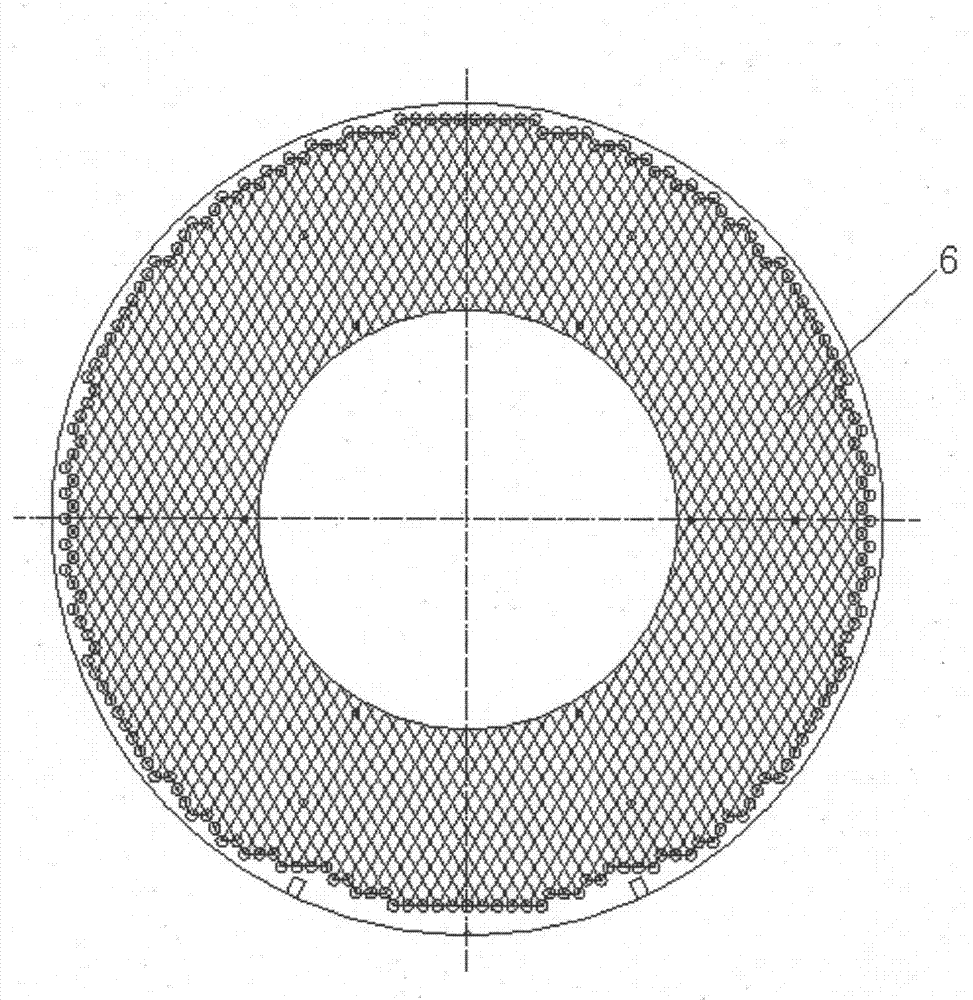

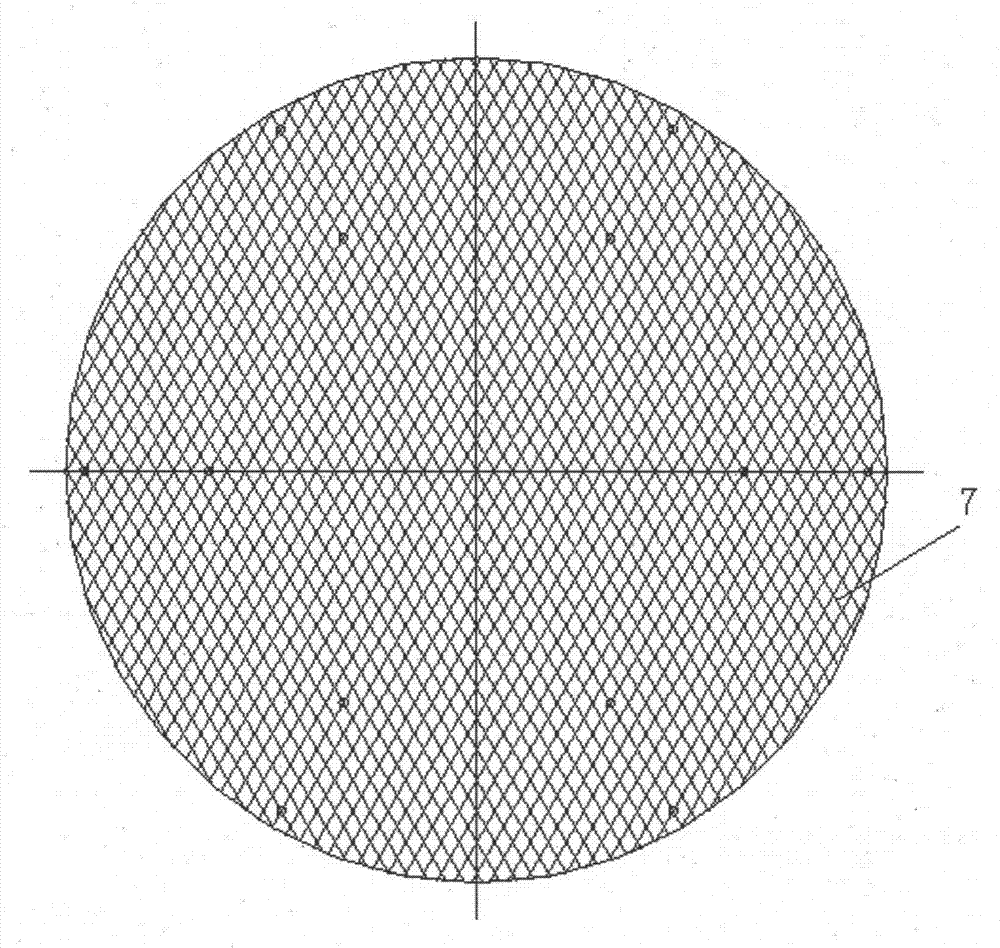

[0020] Such as figure 1 As shown, the present invention provides a disc-annular baffle floating head heat exchanger with temperature control function, which includes a shell 10, and a head structure 11 and a floating head tail structure are respectively arranged at both ends of the shell 10. 12. A head cavity is provided in the head structure 11, and the tube-side inlet 1 located on the head structure 11 communicates with the head cavity, and tube-side fluids separated from each other are provided in the floating-head tail structure 12 The cavity and the shell-side fluid cavity, the shell-side inlet 8 and the tube-side outlet 9 located on the floating head type tail structure 12 communicate with the shell-side fluid cavity and the tube-side fluid cavity respectively, and the shell-side fluid cavity is connected to the shell-side f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com