Orthogonal decoupling six-dimensional force sensor

A six-dimensional force sensor and force measurement technology, applied in the direction of measuring force components, etc., can solve the problems of difficult processing and complex structure, and achieve the effects of large overall stiffness, simple measurement principle and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

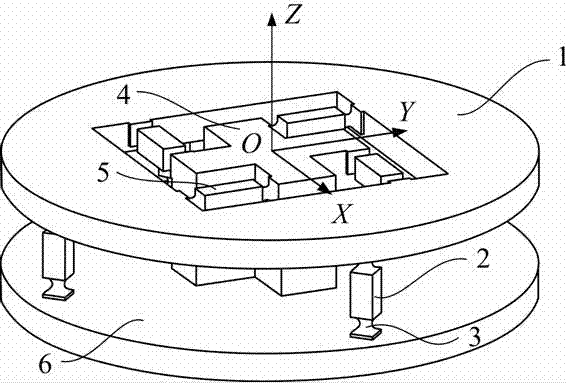

[0025] In this embodiment, the force-measuring platform 1 and the fixed platform 6 are flat plates and placed parallel to each other, and a square through hole is opened in the center of the force-measuring platform 1 . The bottom end of the column 4 is fixedly connected with the fixed platform 6 . The column 4 is a cross-shaped structure with equal cross-section; the horizontal and vertical sides of the column 4 are equal in length; the fixed platform 6 and the force-measuring platform 1 are of equal-diameter structure and arranged concentrically.

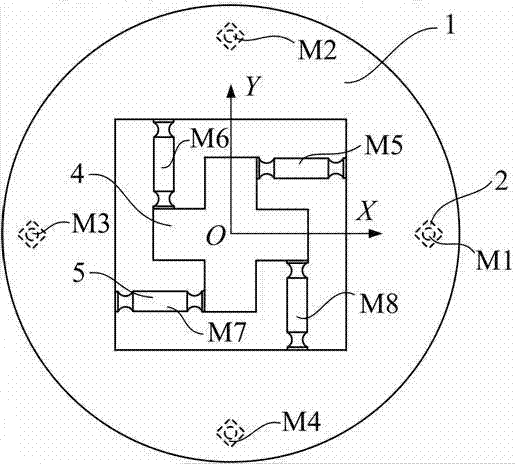

[0026] A group of vertical detection branches 2 are set to four evenly distributed around the axis of the column 4, and each vertical detection branch 2 is represented by M1, M2, M3 and M4 respectively, as figure 2 shown in . Both ends of each vertical detection branch 2 are respectively connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com