RBI dynamic correction method based on fault analysis

A dynamic correction and fault analysis technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as frequent faults, no consideration of real-time status of equipment, low risk level, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Taking an implementation case in a petrochemical enterprise as an example, the present invention, the dynamic correction method of RBI based on failure analysis, is further explained.

[0026] Take the demethanizer (DA-301N: nominal wall thickness 16mm, design pressure 0.81Mpa, diameter 2400mm, design temperature -32℃, measured minimum wall thickness 15.6mm, corrosion rate 0.03mm / year) of an ethylene cracking unit as an example, RBI The risk assessment obtained the risk level of the equipment as low risk. In this example, the "recent" of the time node for the dynamic correction of the RBI for the failure analysis of the equipment is the most recent 6 months.

[0027] When a new failure occurs in the demethanizer, the failure record is added to the equipment data monitoring system, and the equipment's failure statistics are shown in Table 4.

[0028] Table 4 Recent (6 months) breakdown statistics

[0029]

[0030]

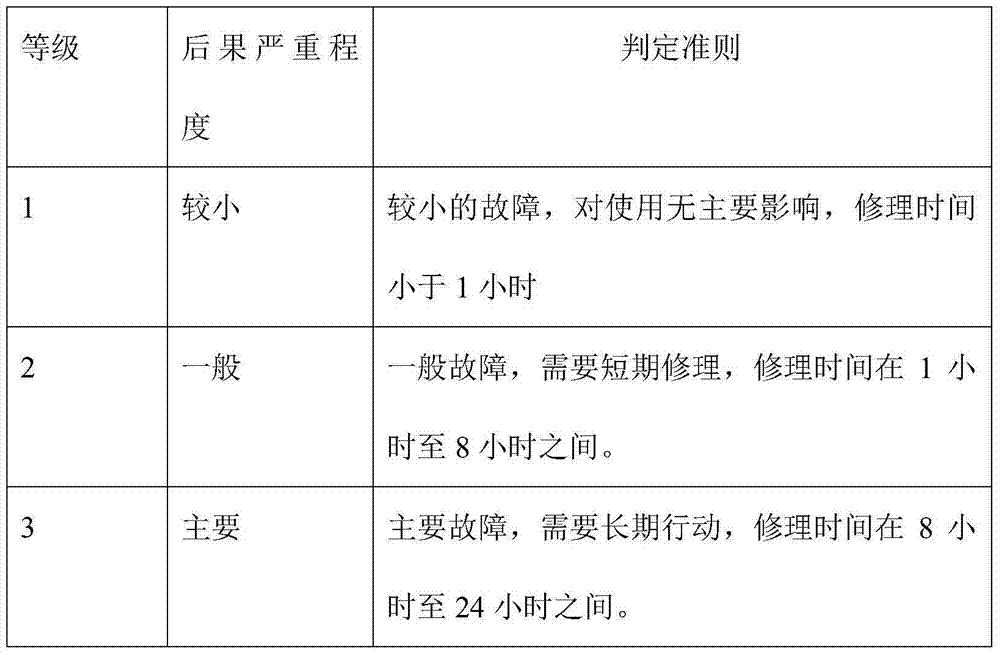

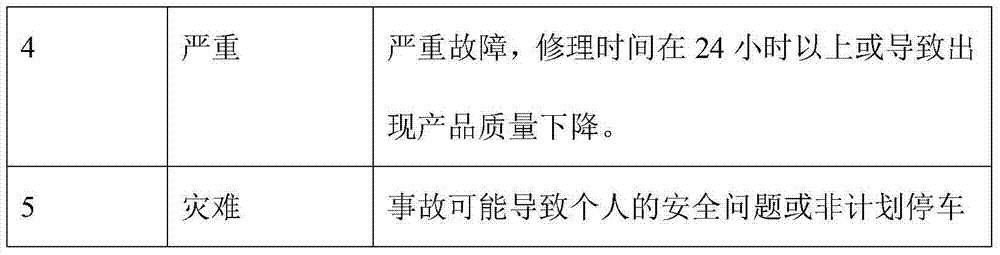

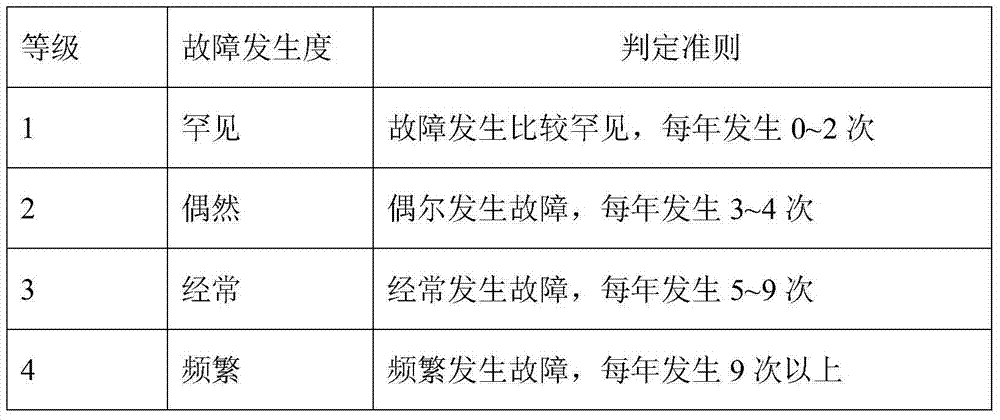

[0031] The division rules of the severity of failure consequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com