A kind of power semiconductor device and its manufacturing method

A technology of power semiconductors and devices, which is applied in the field of electronics, can solve the problems of reduced device shutdown reliability, device burnout failure, dynamic avalanche effect, etc., and achieve the effects of improving reliability, reducing hole injection efficiency, and suppressing current concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing, describe technical scheme of the present invention in detail:

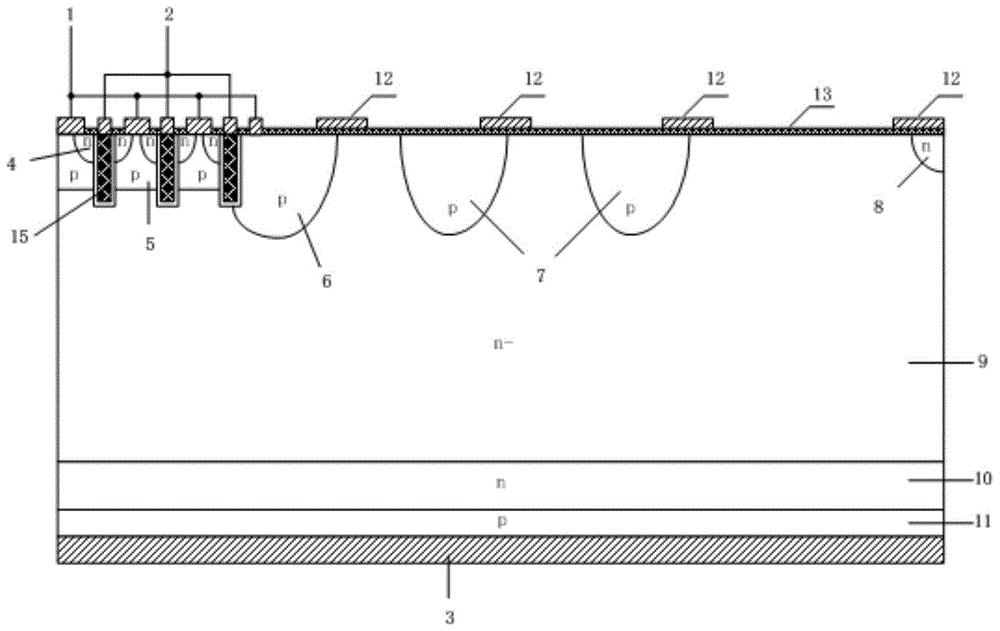

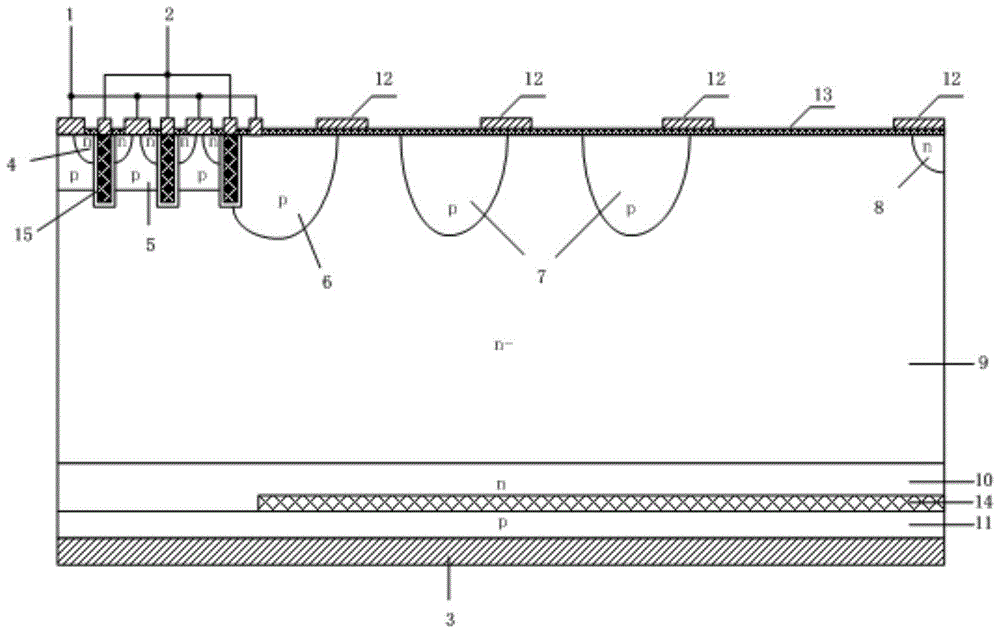

[0041]The invention provides a terminal structure of a power semiconductor device, the structure of which is as follows figure 2 shown. Among them, 1 is the metal emitter, 2 is the gate, 3 is the metal collector, 4 is the n-type source region, 5 is the p-type body region, 6 is the p-type equipotential ring, 7 is the p-type field limiting ring, and 8 is the N-type stop ring, 9 is the n-drift region, 10 is the n-type buffer layer, 11 is the p-type collector region, 12 is the field plate, 13 is the field oxide layer, and the oxide layer 14 is in the n-type buffer layer 10 in the device terminal area and between the p-type collector region 11.

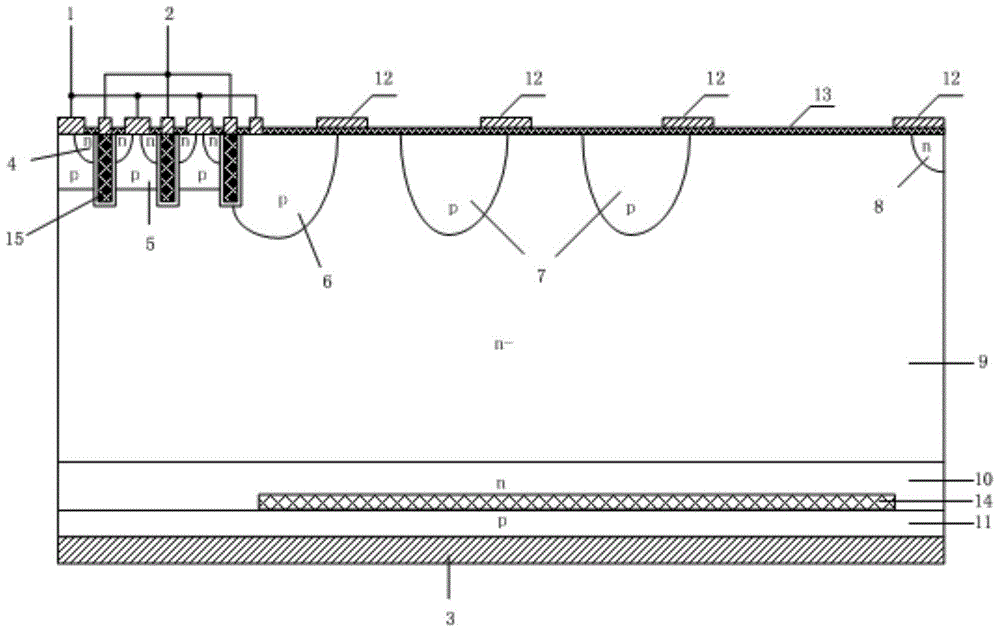

[0042] image 3 It is a structural diagram of another IGBT with a terminal structure of the present invention, and the oxide layer 14 has a certain distance from the edge of the device, which can further prevent the ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com