Device for transmitting force

A technology of equipment and transmission mechanism, applied in the field of force transmission equipment, can solve problems such as complex structure, and achieve the effect of compact structure, simple and compact equipment structure, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

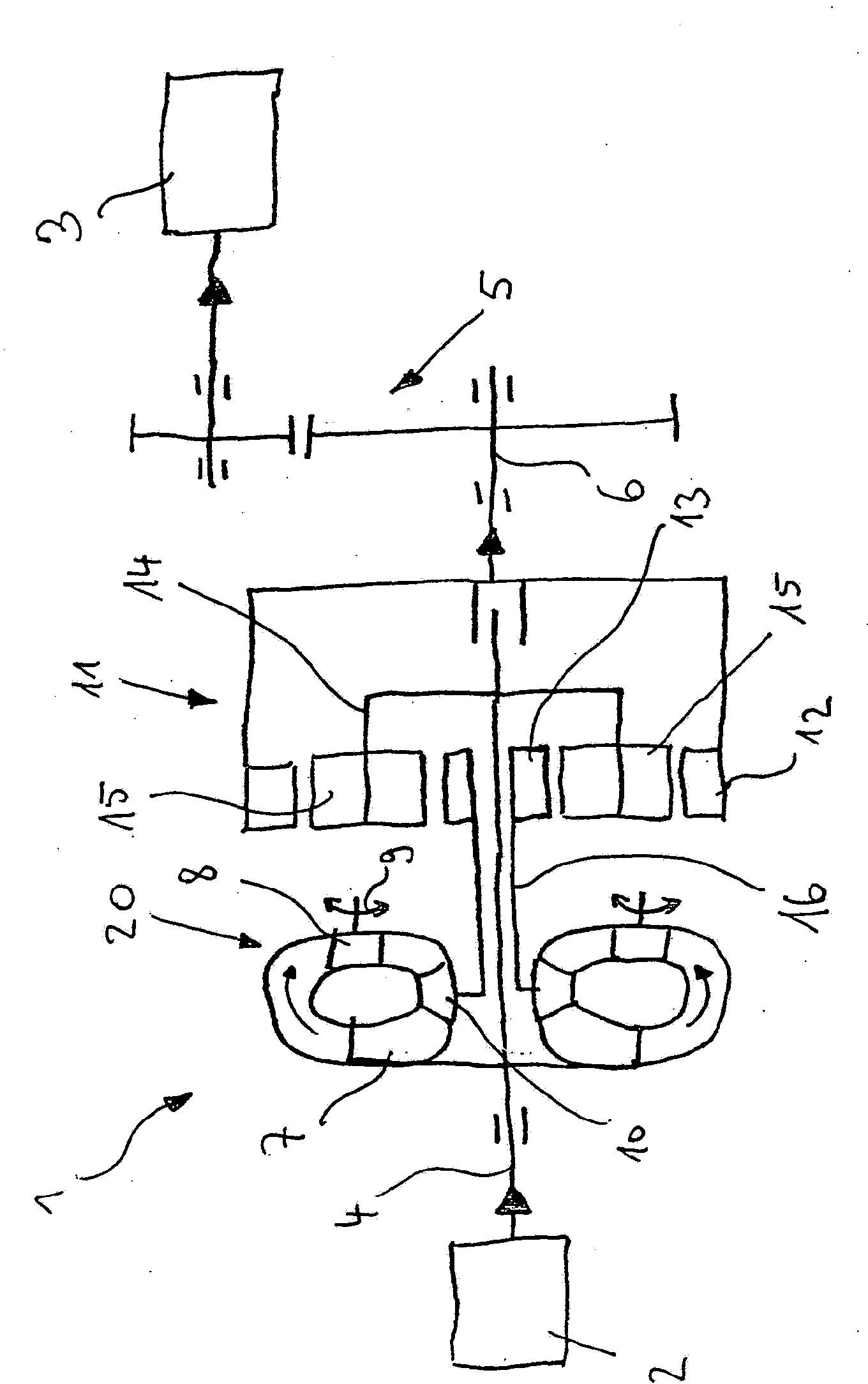

[0014] In the single figure, a device 1 for power transmission is shown, which connects a drive unit 2 and a working machine 3 to one another. In this case, the drive assembly 2 can be designed in particular as a motor, particularly preferably as an electric motor. In the construction shown here, this typically provides a constant rotational speed at which the drive assembly drives the input shaft 4 , which is connected to the drive directly or optionally also via a transmission stage not shown. Component connections. A work machine 3 is then driven via the device 1 , which is designed as a work machine 3 with a variable rotational speed. The work machine 3 can in particular be a compressor or air compressor, a centrifugal pump or the like. In the exemplary embodiment shown here, the working machine is indirectly connected via a spur gear 5 to an output shaft 6 . A connection via a planetary gear, bevel gear or the like is likewise conceivable. The device 1 for power trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com