An automatic detection system for mold hot runner glue leakage

A mold hot runner and automatic detection technology, applied in the field of injection molds, can solve the problems of high maintenance cost, cumbersome detection, low efficiency, etc., and achieve the effect of reducing inspection time under the machine, reducing maintenance cost, and avoiding large-scale damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

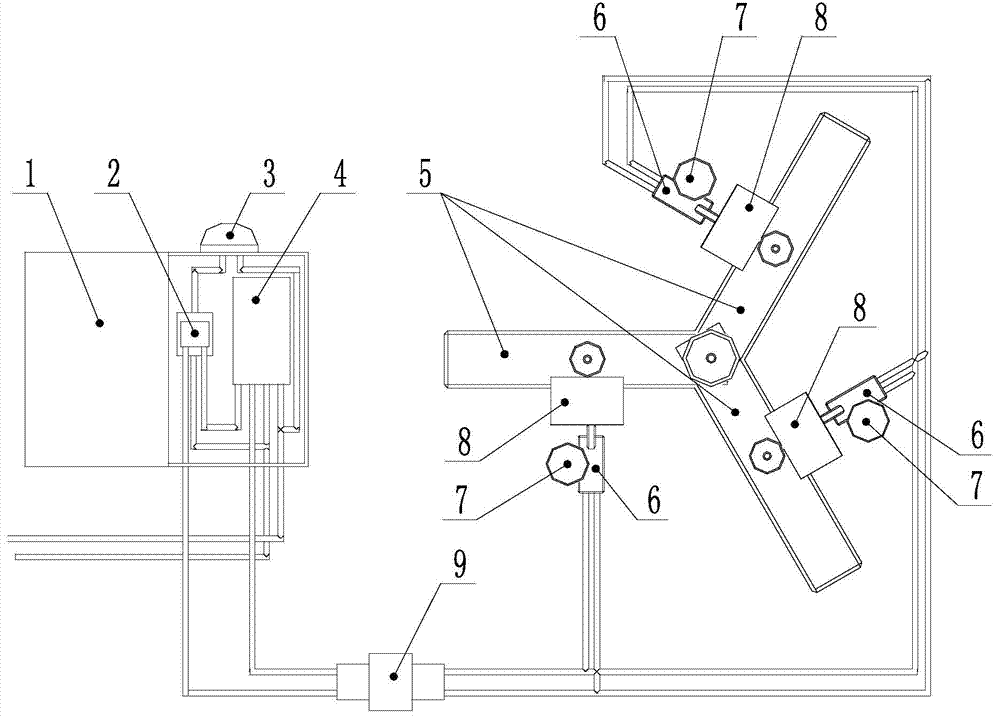

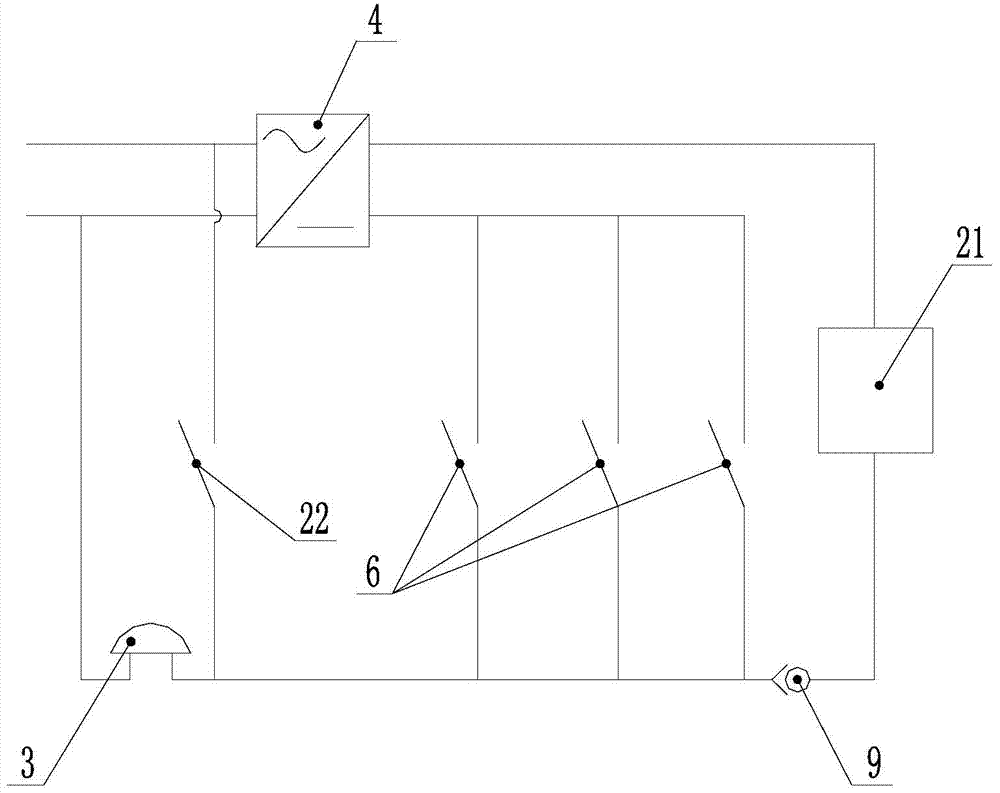

[0028] This embodiment is an automatic detection system for glue leakage in a mold hot runner, such as figure 1 As shown, it includes an alarm device, a detection unit and a power control unit, and both the alarm device and the detection unit are electrically connected to the power control unit; the power control unit includes a bidirectional power supply 4 and a relay 2, and the detection unit includes a sensing contact piece 8 and a limit switch 6 And aviation plug 9; Alarm device and relay contact 22 are connected in series at the high voltage end of bidirectional power supply 4;

[0029] In the present embodiment, the alarm device is an alarm bell 3 (electric bell), the low-voltage terminal voltage of the bidirectional power supply 4 is 24V, and the high-voltage terminal voltage is 220V; the relay is a 24V relay, and one end of its coil is connected with the low-voltage terminal of the bidirectional power supply 4, and the other end is connected with the low-voltage termina...

Embodiment 2

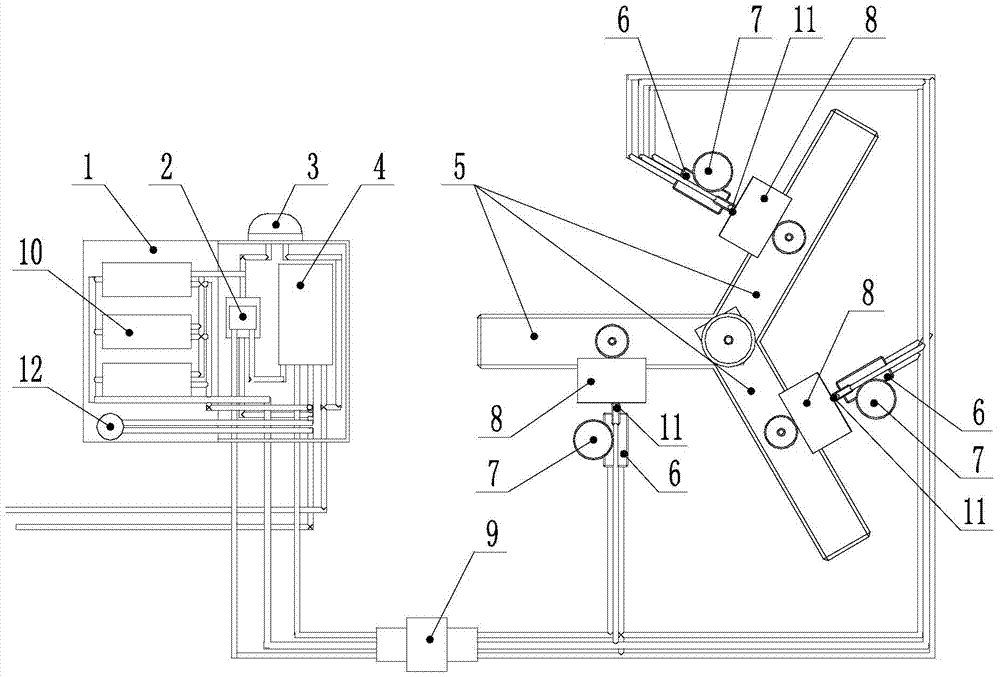

[0038] The difference between this embodiment and Embodiment 1: a temperature sensing probe 11 is provided on the sensing contact sheet 8, a temperature display controller 10 is also installed in the distribution box 1, and the sensing contact sheet 8 is electrically connected to the temperature display controller 10. connection to detect the glue leakage of each hot runner glue port at any time. There is also a master switch (stop switch) 12 used to control the circuit on and off of the entire system, such as image 3 As shown, the temperature display controller 10 is connected in parallel with the limit switch 6 and the aviation plug 9, and is connected in parallel with the relay 2.

[0039] Such as Figure 4 As shown, the circuit of this embodiment also includes a detection circuit loop and an alarm circuit loop, specifically as follows:

[0040] Detection circuit loop: the aviation plug 9 and the limit switch are connected in series, and after the two are connected in ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com