Calcium sulphoaluminate or calcium sulphoaluminate-calcium oxide concrete expanding agents as well as preparation method and application thereof

A technology of calcium sulfoaluminate and calcium oxide, which is applied to improve the performance of concrete against drying shrinkage and temperature shrinkage, calcium sulfoaluminate or calcium sulfoaluminate-calcium oxide full clinker concrete expansion agent and its preparation field It can solve the problems that the rotary kiln cannot be industrialized, the firing process is difficult to control, and the sintering temperature range is narrow, so as to eliminate and reduce clinker ring formation, increase output, and increase clinker output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-11

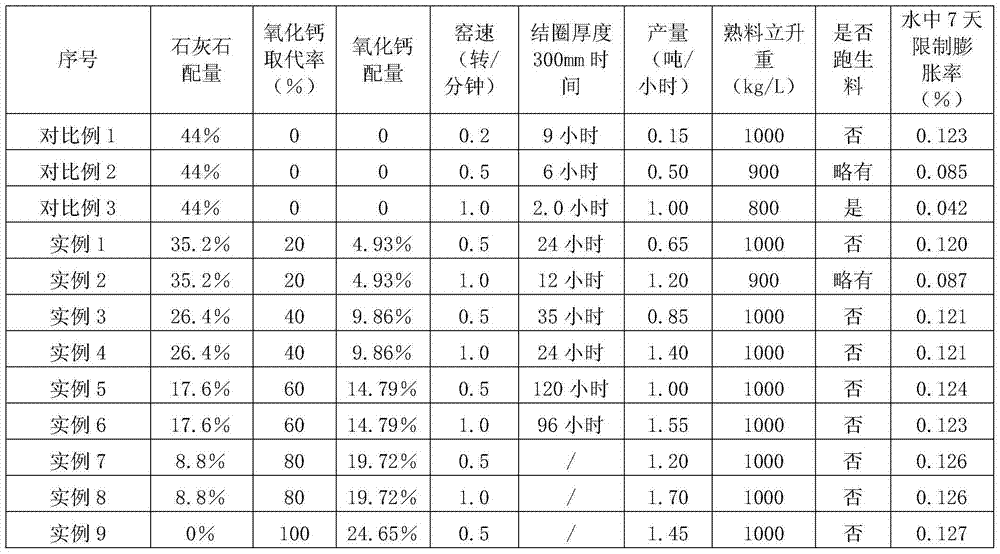

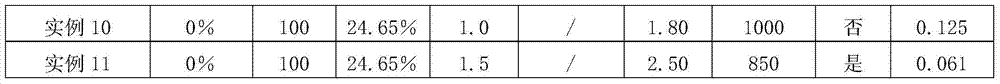

[0051] Example 1-11. Preparation of calcium sulfoaluminate-based fully clinker concrete expansion agent and performance testing

[0052] In the raw material formula of the calcium sulfoaluminate type full clinker concrete expansion agent shown in Table 1, the total amount of limestone used is 44wt% (comparative examples 1, 2, 3), and replaces limestone with different calcium oxide amounts simultaneously (embodiment 1-11), the change is set according to Table 1; the dosage of anhydrite is 42wt%, and the dosage of alumina is 14wt%.

[0053] The batching amount of calcium oxide is calculated according to the content of calcium oxide in calcium carbonate, that is, 1 part by weight of calcium oxide is equivalent to 1.785 parts by weight of calcium carbonate.

[0054] The preparation method of the expansion agent is: use a hollow rotary kiln (model φ1.6×32m) with a diameter of 1600mm hot end to expand to 1900mm, calcinate the raw materials as listed in Table 1, and use coal powder w...

example 12-17

[0061] Example 12-17. Preparation of calcium sulfoaluminate-calcium oxide full clinker concrete expansion agent and performance testing

[0062] In the raw material formula of calcium sulfoaluminate-calcium oxide full clinker concrete expansion agent shown in Table 2, the total amount of limestone is 75wt% (comparative examples 4, 5, 6), and different amounts of calcium oxide Limestone (Example 12-17) is replaced, and its changes are set according to Table 2; the amount of anhydrite is 20wt%; the amount of alumina is 5wt%.

[0063] The dosage of calcium oxide is calculated according to the content of calcium oxide in calcium carbonate, that is, 1 part of calcium oxide is equivalent to 1.785 parts of calcium carbonate.

[0064] Example 12-17 The preparation method of calcium sulfoaluminate-calcium oxide full clinker concrete expansion agent is as follows: use a four-stage cyclone preheater kiln (model φ2.8×46m) with a diameter of 2800mm to calcinate raw materials, and use a cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com