A kind of polymer emulsion and preparation method thereof

A technology of polymer emulsion and emulsion, applied in coating and other directions, can solve the problems of complicated operation process, and achieve the effect of simple process, easy synthesis and short reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

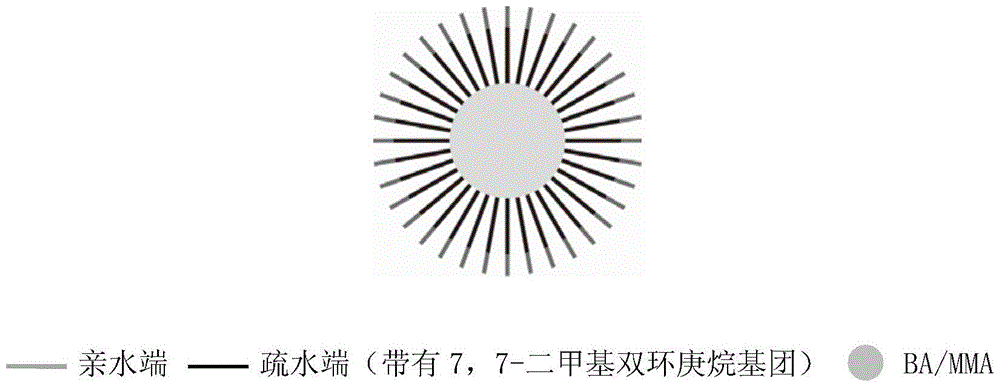

Image

Examples

Embodiment 1

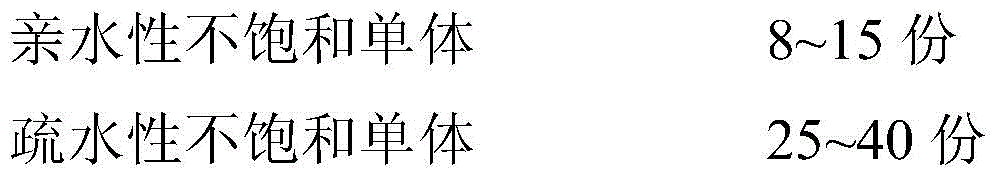

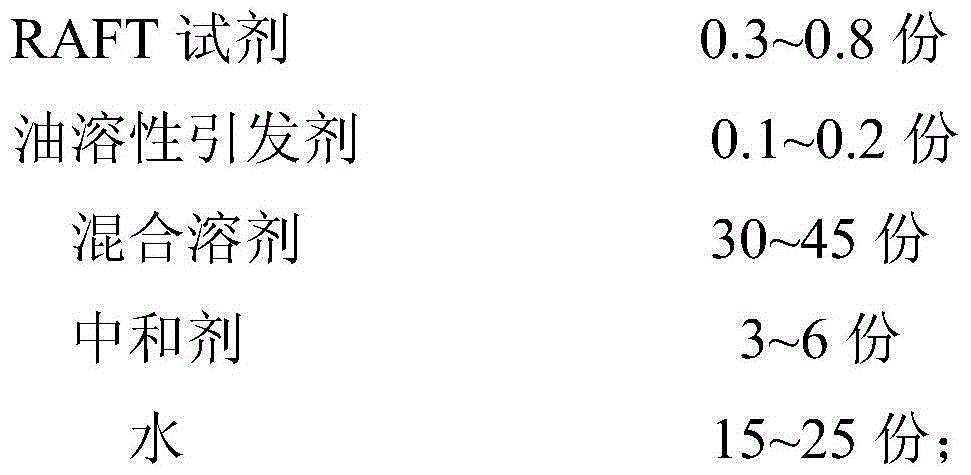

[0038] 1) Preparation of structured amphiphilic block copolymers by RAFT polymerization

[0039] The monomer composition is acrylic acid and isobornyl acrylate, the RAFT reagent composition is 2-{[(dodecylthio)thioformyl]sulfanyl}succinic acid (DCTSS), and the initiator composition is 4'4- Azobis(cyanovaleric acid), the mixed solvent is composed of absolute ethanol and butanone, and the neutralizing agent is composed of triethylamine, and its composition formula is as follows:

[0040] The mass ratio of acrylic acid to isobornyl acrylate is 1:3, and the molar ratio of acrylic acid to 2-{[(dodecylthio)thioformyl]sulfanyl}succinic acid (DCTSS) is 80:1.

[0041]

[0042] First, acrylic acid macromolecular chain transfer agent (PAA-RAFT) was synthesized. Dissolve 1.65 grams of DCTSS in 80 grams of mixed solvent, add it to a reaction kettle equipped with a thermometer, a stirrer, a temperature-controlled heating device and a condensing reflux device, and raise the temperature t...

Embodiment 2

[0049] 1) Preparation of structured amphiphilic block copolymers by RAFT polymerization

[0050] The monomer composition is acrylic acid and isobornyl acrylate, the RAFT reagent composition is 2-{[(dodecylthio)thioformyl]sulfanyl}succinic acid (DCTSS), and the initiator composition is 4'4- Azobis(cyanovaleric acid), the mixed solvent is composed of absolute ethanol and butanone, and the neutralizing agent is composed of triethylamine, and its composition formula is as follows:

[0051] The mass ratio of acrylic acid to isobornyl acrylate is 1:4, and the molar ratio of acrylic acid to 2-{[(dodecylthio)thioformyl]sulfanyl}succinic acid (DCTSS) is 80:1.

[0052]

[0053] First, acrylic acid macromolecular chain transfer agent (PAA-RAFT) was synthesized. Dissolve 1.65 grams of DCTSS in 80 grams of mixed solvent, add it to a reaction kettle equipped with a thermometer, a stirrer, a temperature-controlled heating device and a condensing reflux device, and raise the temperature t...

Embodiment 3

[0060] 1) Preparation of structured amphiphilic block copolymers by RAFT polymerization

[0061] The monomer composition is acrylic acid and isobornyl acrylate, the RAFT reagent composition is 2-{[(dodecylthio)thioformyl]sulfanyl}succinic acid (DCTSS), and the initiator composition is 4'4- Azobis(cyanovaleric acid), the mixed solvent is composed of absolute ethanol and butanone, and the neutralizing agent is composed of triethylamine, and its composition formula is as follows:

[0062] The mass ratio of acrylic acid to isobornyl acrylate is 1:5, and the molar ratio of acrylic acid to 2-{[(dodecylthio)thioformyl]sulfanyl}succinic acid (DCTSS) is 80:1.

[0063]

[0064]

[0065] First, acrylic acid macromolecular chain transfer agent (PAA-RAFT) was synthesized. Dissolve 1.65 grams of DCTSS in 80 grams of mixed solvent, add it to a reaction kettle equipped with a thermometer, a stirrer, a temperature-controlled heating device and a condensing reflux device, and raise the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com