Biodegradable bentonite lubricating grease composition and preparation method thereof

A technology of bentonite lubricating grease and lubricating grease composition, which is applied in the field of lubricating grease, can solve the problems of being unable to meet the urgent needs of human beings to protect the environment, poor biodegradability, and high ecotoxicity, and achieve high cost performance, stable product quality, and good market value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

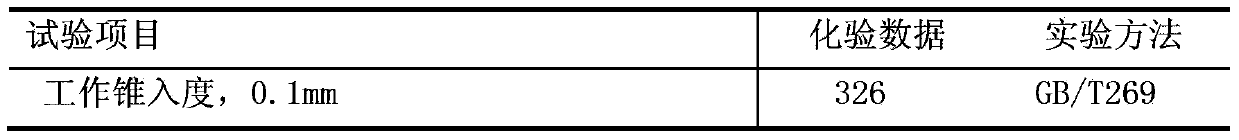

[0020] Take 1000g of base oil (trihydroxypropane ester with a viscosity of 30mm at 40°C) 2 / s, the viscosity index is 120) into the reaction kettle, then add 110g of bentonite (baragel10) into the reaction kettle, stir slowly and heat to 60°C, add 10.5g of auxiliary dispersant (acetone) and stir rapidly, and keep the temperature at 20 minute. Heat the material to 100°C, keep the temperature constant for 0.5 hours, add 500g of base oil, and raise the temperature to 160°C, keep the temperature constant for 0.5 hours, add 500g of quench oil base oil, drop the temperature to 80°C, add 2.1g of antioxidant (T501), and keep the temperature for 10 Minutes, carry out post-processing after stirring, the performance of the lubricating grease that the present invention's technological formula makes is listed in table 1

[0021] Table 1

[0022]

[0023]

[0024] It can be known from Table 1 that the grease of the present invention has the characteristics of no dropping point of be...

example 2

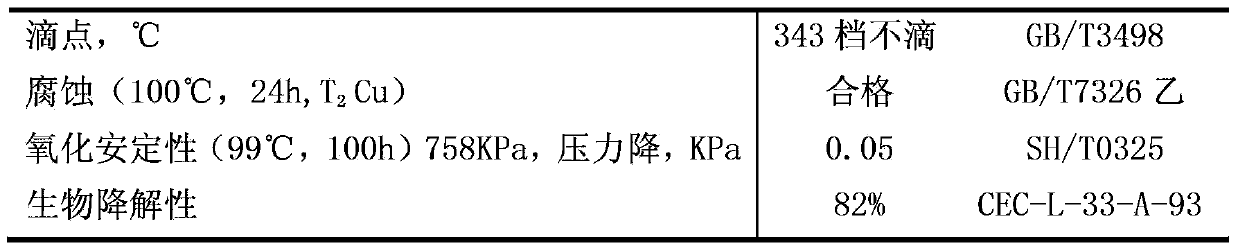

[0027] 1000g of base oil (pentaerythritol ester with a viscosity of 100mm at 40°C 2 / s, the viscosity index is 160) into the reactor, then add 300g of bentonite (baragel10) into the reactor, stir slowly and heat to 80°C, add 32g of auxiliary dispersant (acetone) and stir quickly, and keep the temperature for 50 minutes. Heat the material to 110°C, keep the temperature constant for 1 hour, add 500g of base oil, and raise the temperature to 180°C, keep the temperature constant for 0.5 hours, add 500g of quench oil base oil, drop the temperature to 90°C, add 11.5g of antioxidant (T501), and keep the temperature for 10 Minutes, carry out post-processing after stirring, the performance of the lubricating grease that the technological formula of the present invention makes is listed in Table 2

[0028] Table 2

[0029]

[0030] It can be seen from Table 2 that the grease of the present invention has the characteristics of no dropping point of bentonite grease and is biodegradabl...

example 3

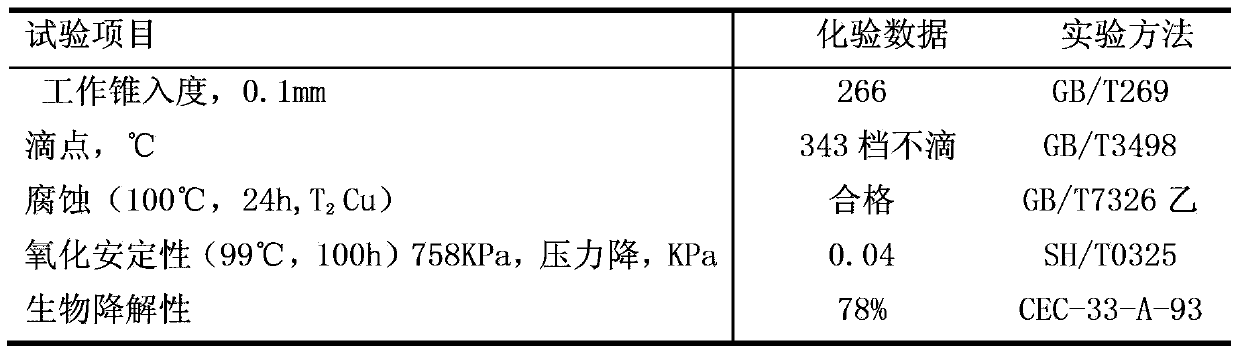

[0033] Add 1500g of base oil (trihydroxypropane ester) into the reaction kettle, then add 700g of bentonite (NYKON77) into the reaction kettle, stir slowly and heat to 80°C, add 50g of auxiliary dispersant (ethanol) and stir quickly, and keep the temperature at 20 minute. Heat the material to 110°C, keep the temperature constant for 0.5 hours, add 200g of base oil, and raise the temperature to 170°C, add 300g of quenching oil base oil, drop the temperature to 100°C, add 25g of antioxidant (rosemary), keep the temperature for 20 minutes, Carry out aftertreatment after stirring evenly, the lubricating grease performance that the present invention's technological formula makes is listed in table 3

[0034] table 3

[0035]

[0036]

[0037] From the data in Table 3, it can be seen that the grease of the present invention has the characteristics of no dropping point of bentonite grease and is biodegradable.

[0038] The test items of this example are only the general items...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com