Magnetron sputtering coating device and coating method

A technology of magnetron sputtering coating and coating equipment, which is applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problem of limited vacuum chamber space of coating device, inability to handle large-scale and structural equipment, and inability to achieve Multi-batch, multi-directional coating and other issues, to achieve the effect of consistent thickness, simple operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The CVD reactor inner wall coating device of the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings, but these embodiments are only for the purpose of illustration and are not intended to limit the scope of the present invention.

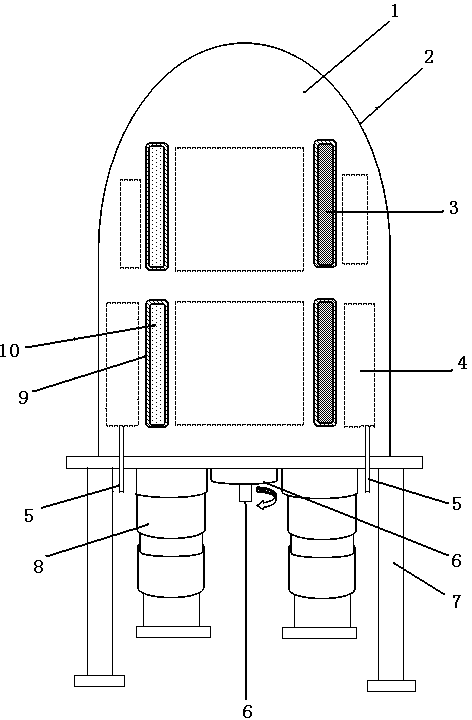

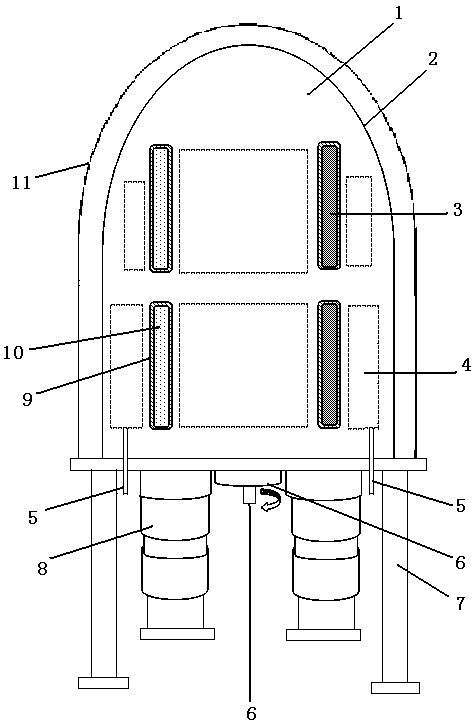

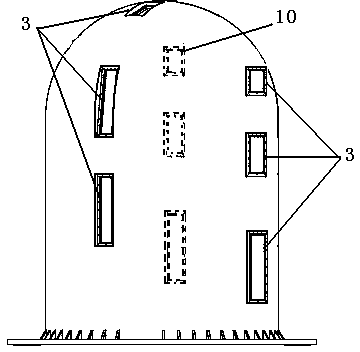

[0034] Such as figure 1 As shown, the CVD reactor inner wall coating device according to the present invention includes a coating equipment main body 1, a frame platform 7, a baffle plate 4, a cooling facility 5 and a pump group 8, wherein the coating equipment main body 1 includes a sleeve 2 , the ion source 10 and the cathode target 3 are fixed on the sleeve 2, the frame platform 7 has multiple connections, and the coating equipment main body 1 is connected to the innermost connection of the frame platform 7. The mechanism to be plated outside the sleeve 2 is connected to the outermost connection of the frame platform 7, and a closed chamber is formed between the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com