Drying device applied to producing high-breathability paper products in papermaking industry

A high-permeability technology, used in papermaking, papermaking, textiles and papermaking, etc., can solve the problems of affecting air permeability, cardboard knots, poor hand feeling, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further described below in conjunction with embodiment (accompanying drawing):

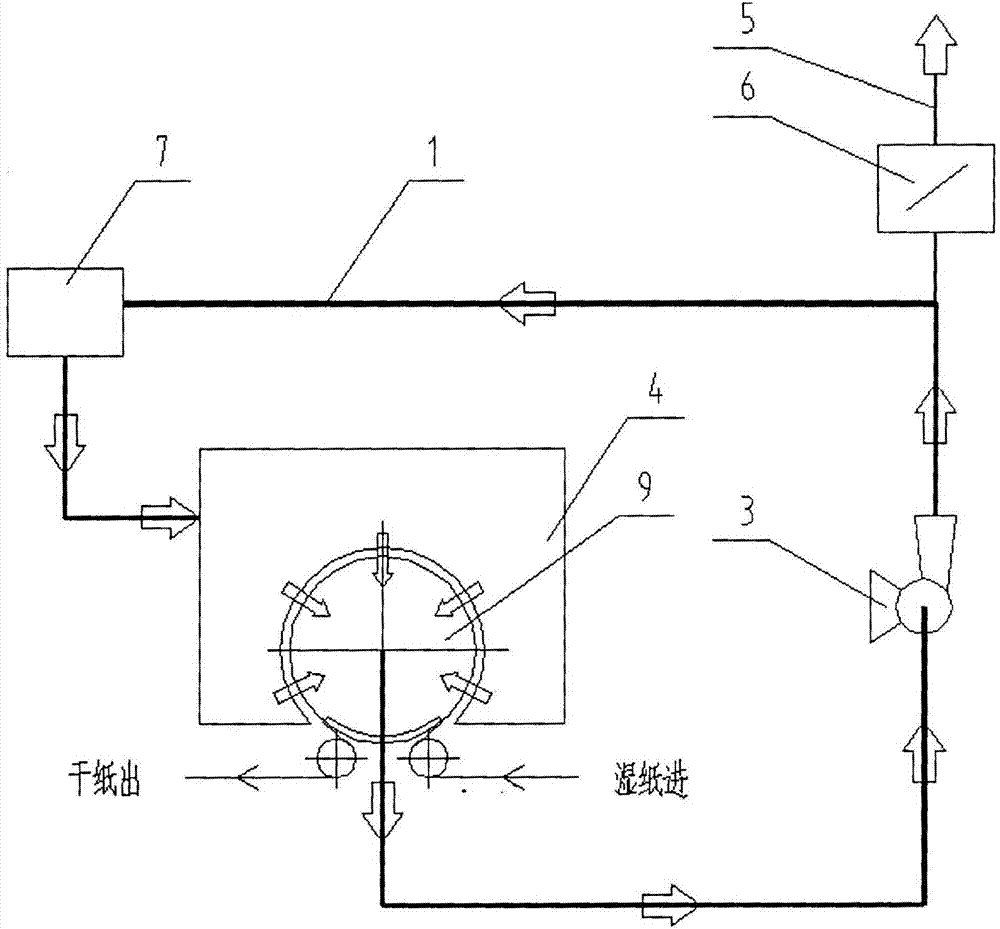

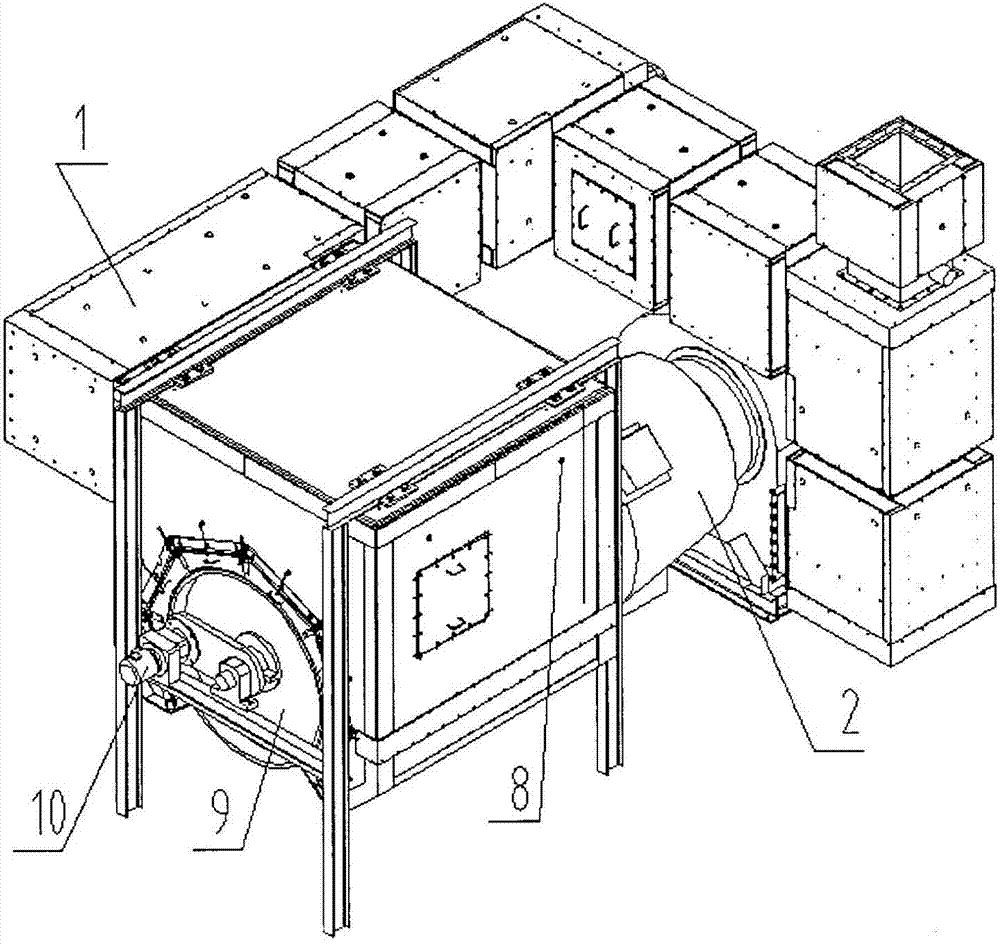

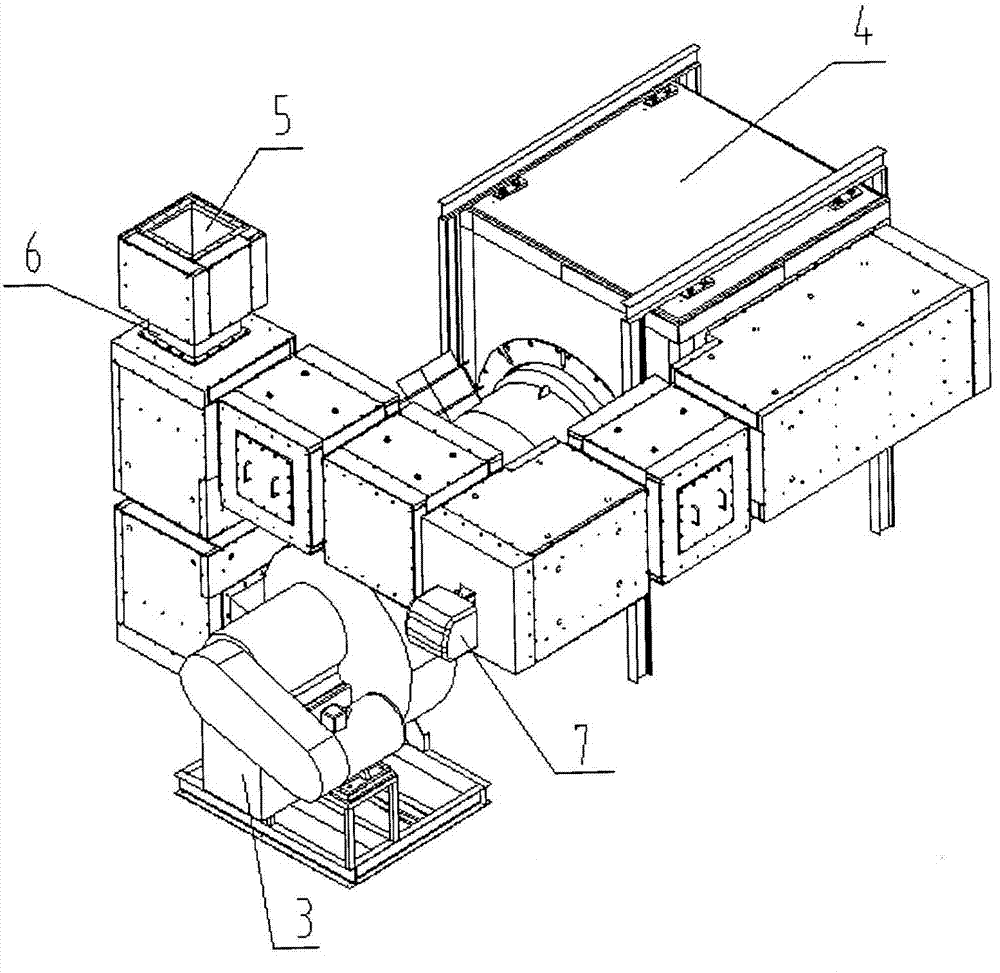

[0020] Such as figure 1 , 2 As shown in , 3, the drying device of the present invention used in the paper industry to produce paper products with high air permeability includes a circulating fan 3 connected in sequence through a circulating air duct 1, a heating device 7, and a honeycomb rotary screen rotary drum inside. 9 drying room 4; the air outlet of the honeycomb rotary drum 9 is connected to the air inlet of the circulation fan 3 through the suction cylinder 2; the circulation air duct between the circulation fan 3 and the burner 7 is provided with a The humidity exhaust air channel 5 is connected and installed with the damper 6; the honeycomb rotary screen rotary cylinder 9 is set in the drying room 4 in a way that is coaxial with the suction cylinder 2 and communicates with the inner cavity, and the honeycomb rotary screen rotates The two ends of the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com