Memory alloy phase-change temperature measuring method and measuring system for implementing same

A memory alloy, phase transition temperature technology, applied in the investigation stage/state change and other directions, can solve the problems of not widely used and high requirements for testing equipment, and achieve the effect of non-destructive measurement of application range, wide application range and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

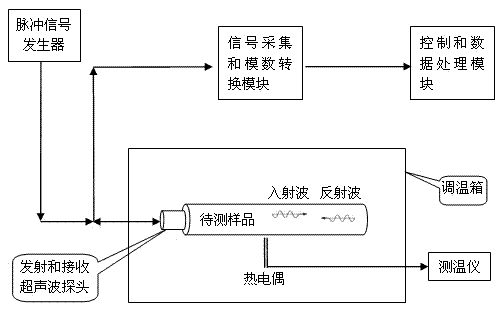

[0022] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

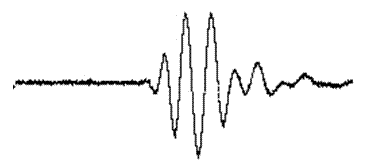

[0023] The idea of the present invention is to use the sensitivity of the ultrasonic longitudinal wave velocity to the phase transition process of the memory alloy to measure the phase transition temperature of the memory alloy. The change law of ultrasonic longitudinal wave velocity with temperature, because the sound velocity will change abnormally near the phase transition point of the shape memory alloy, and there will be obvious inflection points on the sound velocity-temperature curve, which correspond to different phase transition temperatures. According to these inflection points, The phase transition temperature of the memory alloy can be accurately determined.

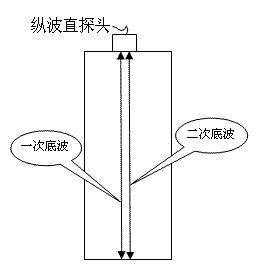

[0024] To realize the measurement method of the present invention, the first problem to be solved is to excite a stable ultrasonic wave in the shape memory alloy sample to be tested;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com