A non-contact electrostatic voltmeter calibration device and calibration method

An electrostatic voltmeter, non-contact technology, applied in measuring devices, measuring electrical variables, instruments, etc., can solve the problems of high inspection cost, difficult transportation, and great danger, and achieve the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

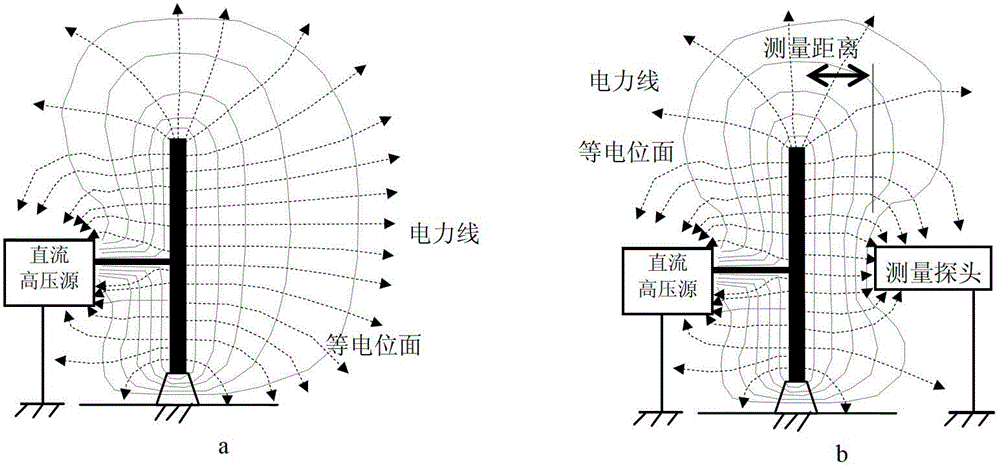

Problems solved by technology

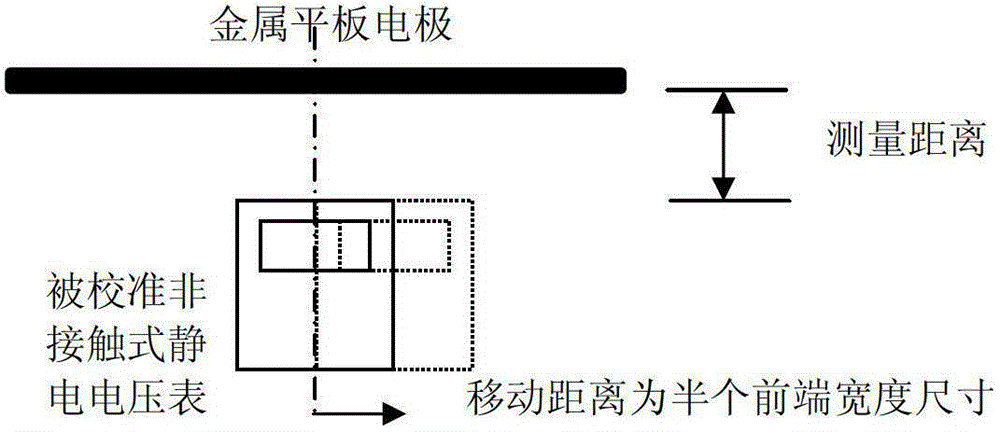

Method used

Image

Examples

Embodiment Construction

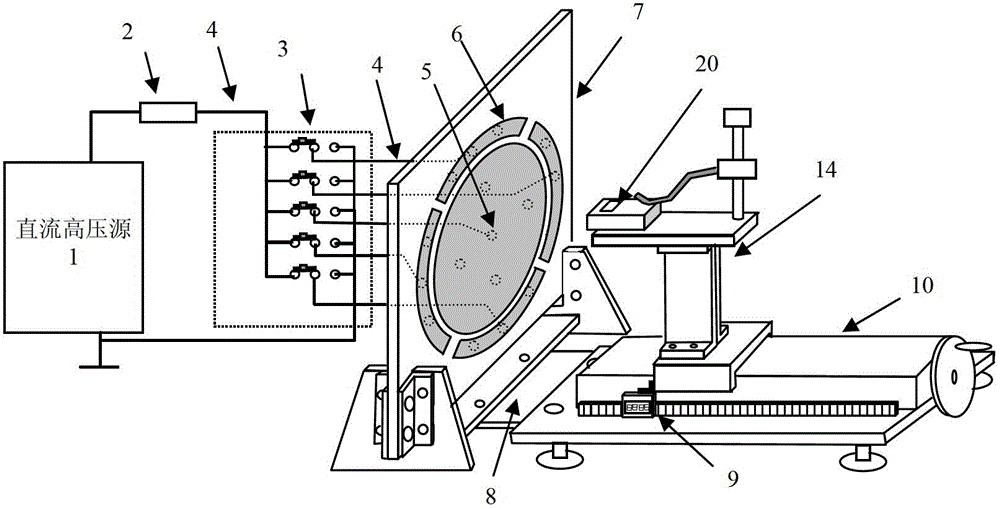

[0056] Such as image 3 As shown, the overall schematic diagram of the device of the present invention, the non-contact electrostatic voltmeter calibration device consists of a DC high voltage source 1, a protection resistor 2, a selector switch 3, a high voltage wire 4, a central metal electrode plate 5, an edge metal electrode plate 6, and a glass substrate support 7. Lap joint plate 8, vernier caliper 9, vertical motion mechanism 10, and calibrated non-contact electrostatic voltmeter 20; the output of DC high-voltage power supply 1 is connected to one end of protection resistor 2, and the other end of protection resistor 2 is connected through high-voltage wire 4 for selection The left pin of the switch 3, the right pin of the selection switch 3 is connected to the ground wire of the DC high voltage source 1, the middle pin of the selection switch 3 is connected to the center metal electrode plate 5 and the edge metal electrode plate 6 through the high voltage wire 4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com