Non-contact pipeline defect detection device with GPS (Global Positioning System) positioning function and detection method

A GPS positioning, non-contact technology, applied in the field of non-contact pipeline defect detection devices, can solve the problems of low contact or distance detection, no positioning function, defects, etc., and achieves shielding magnetic field interference and good anti-interference performance. , the effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

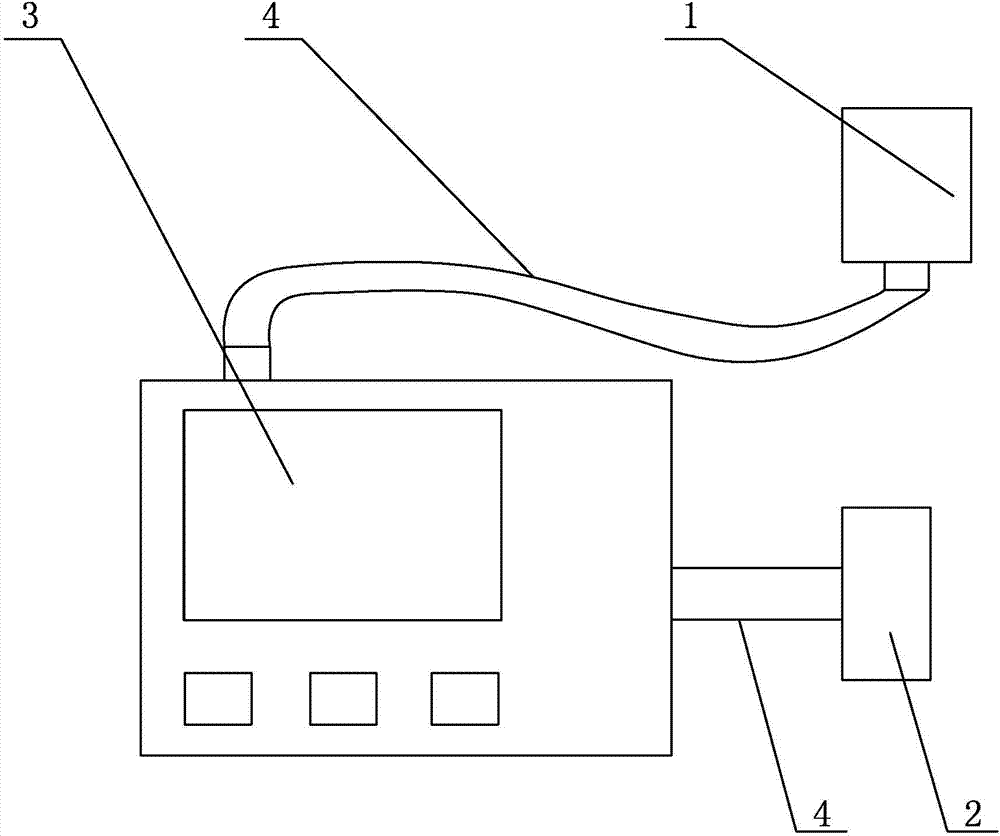

[0016] Specific implementation mode one: combine figure 1 Describe this embodiment, a non-contact pipeline defect detection device with GPS positioning function described in this embodiment includes a scanning mechanism 1, a GPS positioning system 2, a host 3 and two data lines 4, and the data transmission interface of the scanning mechanism 1 Connect with the communication interface of the host 3 through a data line 4, the communication interface of the GPS positioning system 2 is connected with the communication interface of the host 3 through a data line 4, the GPS positioning system 2 is composed of a signal passive receiving antenna and a data processing chip The signal passive receiving antenna is connected with the data processing chip, and the data processing chip is connected with the communication interface. Import the latitude and longitude data stored by the detection equipment into Google Earth, call Google Earth, and draw the detection path on its three-dimension...

specific Embodiment approach 2

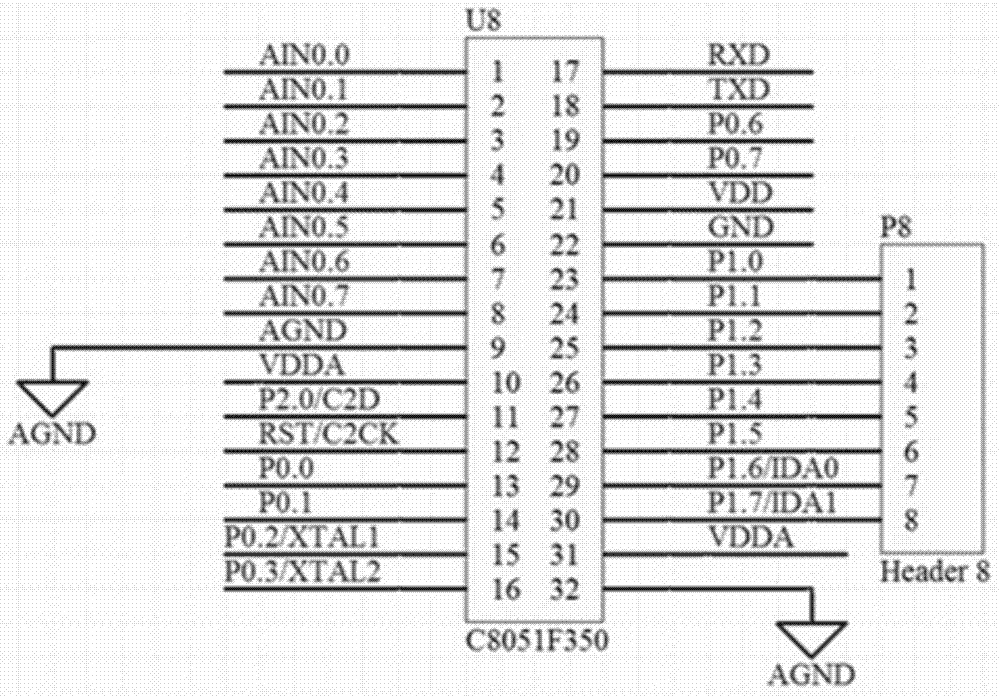

[0018] Specific implementation mode two: combination figure 1 Describe this embodiment. The scanning mechanism 1 of a non-contact pipeline defect detection device with GPS positioning function described in this embodiment is composed of a magnetoresistive sensor, a filter circuit, and a data transmission interface. The magnetoresistive sensor is connected to the filter circuit, and the filter circuit The circuit is connected with the data transmission interface.

[0019] The magnetoresistive sensor in this embodiment selects a magnetoresistive sensor with a sensitivity in the micro-Gauss level, and uses the sensor position reset method and electromagnetic shielding method to design, avoiding electromagnetic waves and interference magnetic fields generated by electromagnetic equipment or other interference magnetic fields existing in the detection environment Effects on testing equipment. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

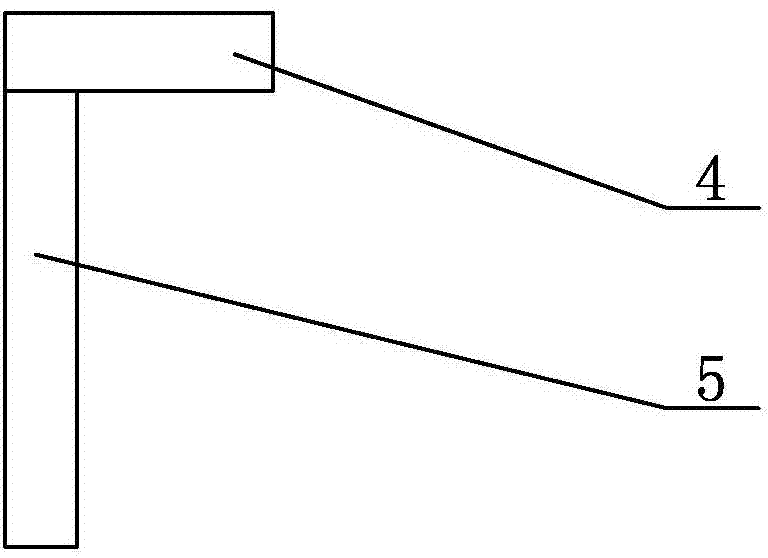

[0020] Specific implementation mode three: combination figure 2 To illustrate this embodiment, the magnetoresistive sensor of a non-contact pipeline defect detection device with GPS positioning function described in this embodiment is composed of a horizontal chip 5 and a vertical chip 6 perpendicular to each other.

[0021] The horizontal chip 5 in the present embodiment is the HMC1001 chip, and it is only sensitive to the magnetic field on one direction, and the vertical chip 6 is the HMC1002 chip, and it is sensitive to the magnetic field of two mutually perpendicular directions, and the horizontal chip 5 and the vertical chip 6 are combined Finally, the magnetic field in three directions can be detected simultaneously. Other components and connections are the same as those in the second embodiment.

[0022] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the specific steps of a pipeline defect detection method using the device des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com