Method for automatically detecting handle loss fault of angle cock of railway wagon

A railway freight car, automatic detection technology, applied in the field of image processing, can solve problems such as time-consuming and laborious maintenance costs, brake system failure, multiple engine failures, etc., to achieve the effect of improving efficiency and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

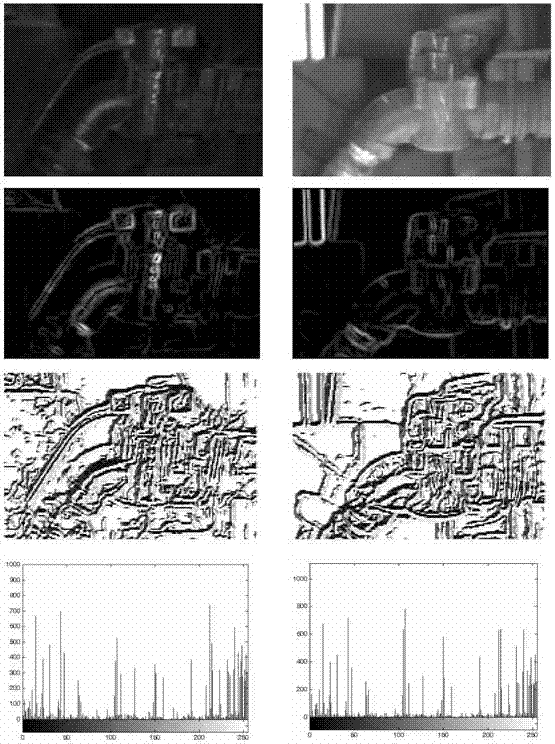

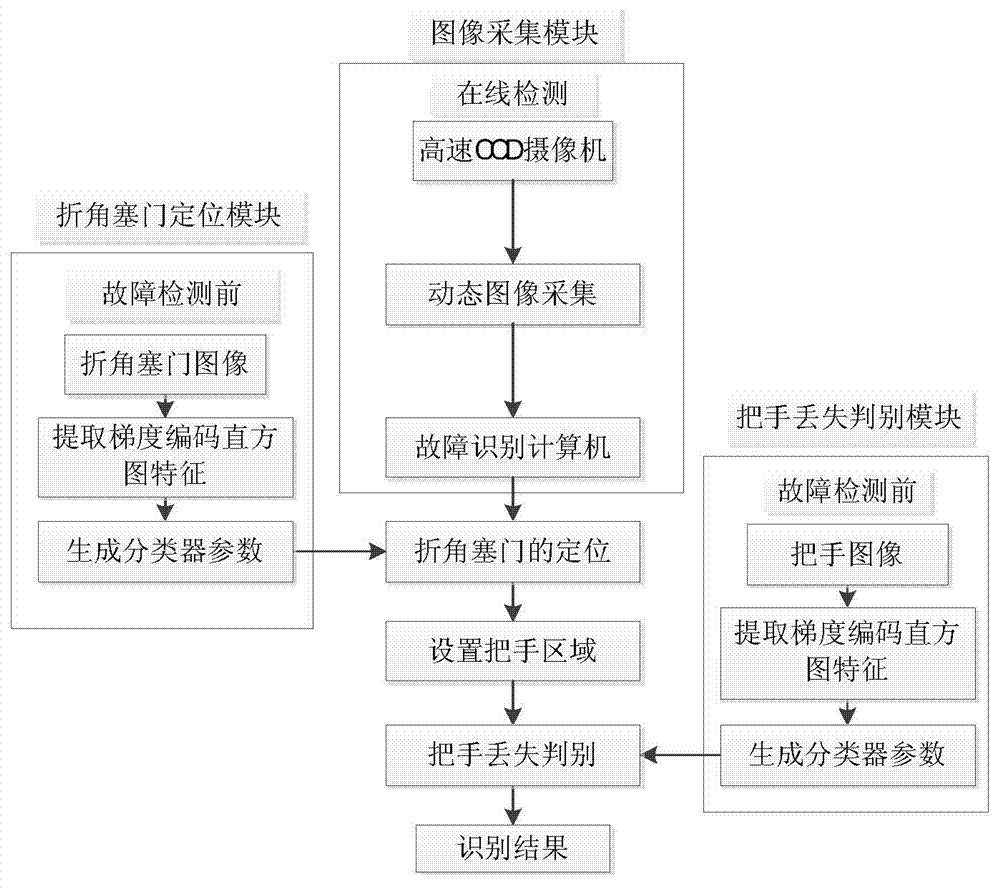

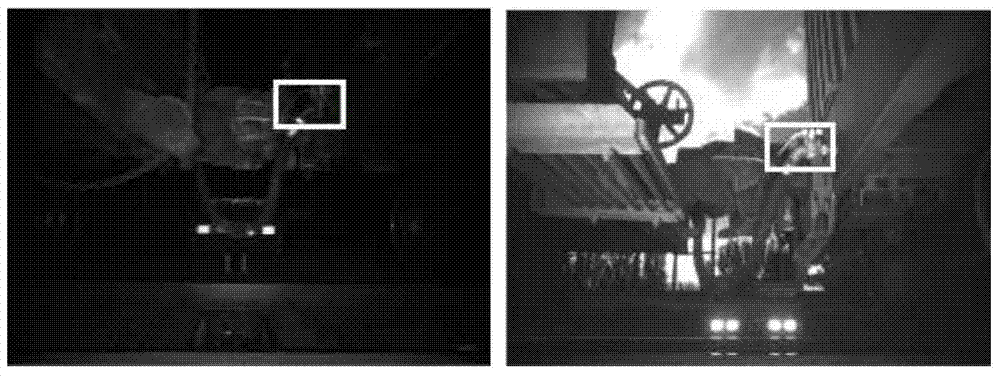

[0019] Such as figure 1 As shown, in this embodiment, the image (1400×1024 pixels) of the angle cock part collected on the railway site is processed. These images have significant lighting changes and complex backgrounds. This embodiment includes the following steps:

[0020] The first step is to sample the image of the knuckle plug part to be analyzed with 4 pixel displacements, intercept a window of 192×128 pixels, and extract the gradient-encoded histogram features, specifically:

[0021] ① Obtain a smooth image I′ by convolving the image I of the knuckle cock with the Gaussian kernel function: I′=I*G(x,y,σ), where * represents the convolution operation, and the standard deviation is the Gaussian kernel with σ The function is G ( x , y , σ ) = 1 2 πσ 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com