OLED (organic light-emitting diode) backboard and manufacturing method for same

A manufacturing method and backplane technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as the complexity of the OLED backplane manufacturing process, and achieve the effect of avoiding discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

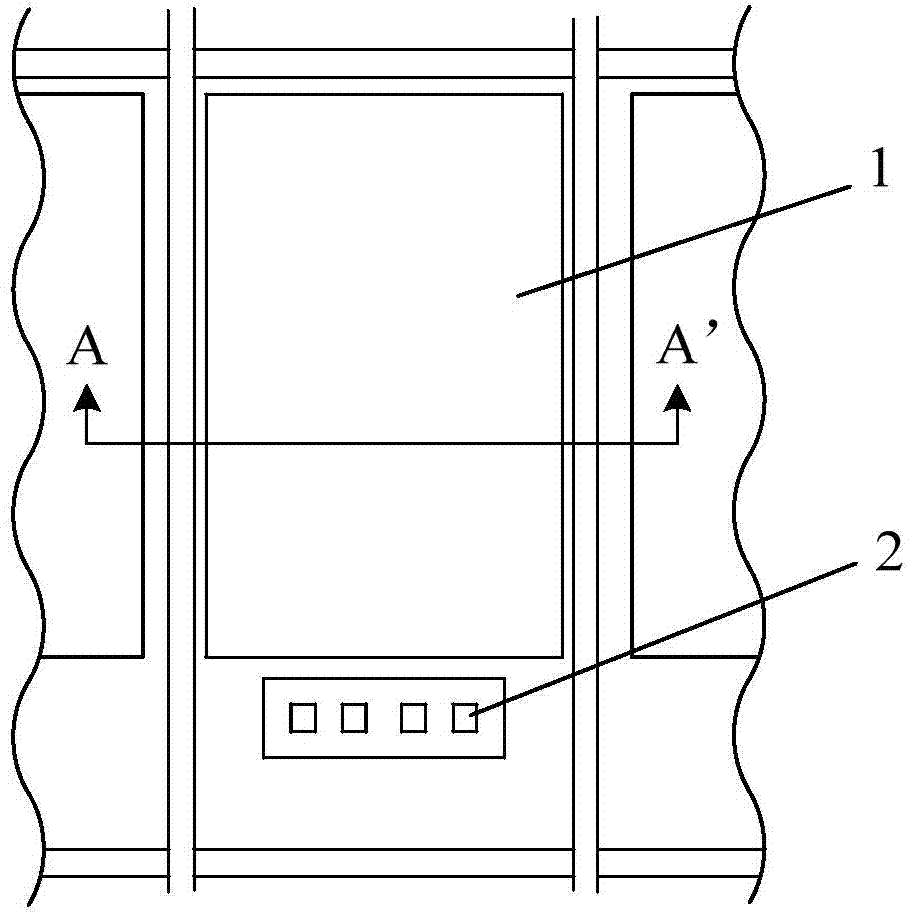

[0048] Such as Figure 6 As shown, the embodiment of the present invention provides a method for manufacturing an OLED backplane, which can be specifically used to manufacture an OLED backplane for an oxide (Oxide) TFT. The manufacturing method includes:

[0049] Step 101, forming a pattern including TFTs on a substrate;

[0050] This step specifically includes forming a gate, a gate insulating layer, an active layer, an etching stopper layer, a source and a drain.

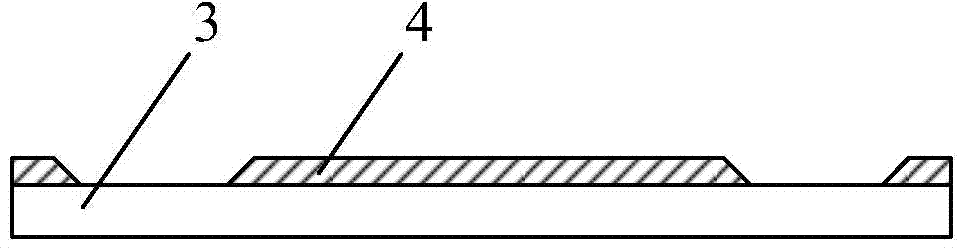

[0051] Step 102, such as Figure 7 As shown, a passivation layer 3 is formed on the substrate including the above TFT pattern;

[0052] Step 103, forming a color filter 4 on the substrate including the passivation layer 3;

[0053] Specifically, it includes spin-coating the color filter material on the substrate, and sequentially performing exposure, development and annealing.

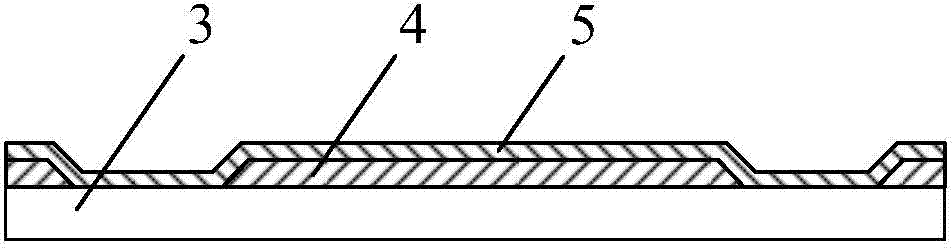

[0054] Step 104, forming a resin layer 8 on the substrate including the color filter 4;

[0055]Specifically, the resin material is ...

Embodiment 2

[0066] On the basis of Embodiment 1, the embodiment of the present invention provides a method for manufacturing an OLED backplane, such as Figure 11 As shown, among them,

[0067] The above step 104, forming a resin layer on the substrate including the above color filter specifically includes:

[0068] Step 1041, such as Figure 12 As shown, a resin material 81 is deposited on the substrate including the color filter 4;

[0069] Step 1042, such as Figure 8 As shown, the resin material in the pixel electrode area 1 is lightly exposed by halftone exposure, and the resin material in the passivation layer via hole area 2 and its surrounding area is deeply exposed by halftone exposure, finally forming a Figure 13 Resin layer 8 is shown.

[0070] Specifically, the resin material in the pixel electrode region 1 is lightly exposed to thin the resin layer in this region, further ensuring the conductivity of the heavily doped resin layer in this region; similarly, the passivatio...

Embodiment 3

[0076] On the basis of Embodiment 1, the embodiment of the present invention provides a method for manufacturing an OLED backplane, such as Figure 13 As shown, among them,

[0077] The above-mentioned step 104, forming the resin layer 8 on the substrate including the above-mentioned color filter 4 specifically includes:

[0078] Step 1041, depositing a resin material on the substrate including the color filter 4;

[0079] Step 1043: Lightly expose the resin material in the pixel electrode area 1 by halftone exposure, and perform deep exposure on the resin material around the passivation layer via hole area 2 by halftone exposure, and expose the resin material in the passivation layer via hole area 2 Take full exposure.

[0080] Specifically, step 1043 is similar to step 1042 in the second embodiment, the only difference is that in step 1043, the resin material in the passivation layer via area 2 is fully exposed, so that the passivation layer via area 2 has no resin materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com