Liquid cooling insulation type radiator

An insulating heat sink technology, applied in the direction of electrical solid devices, semiconductor devices, semiconductor/solid device components, etc., can solve the problems of large cooling system, limited use range and complexity of high-voltage electric transmission devices, and achieve small size, Improve the heat dissipation effect and the effect of large heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

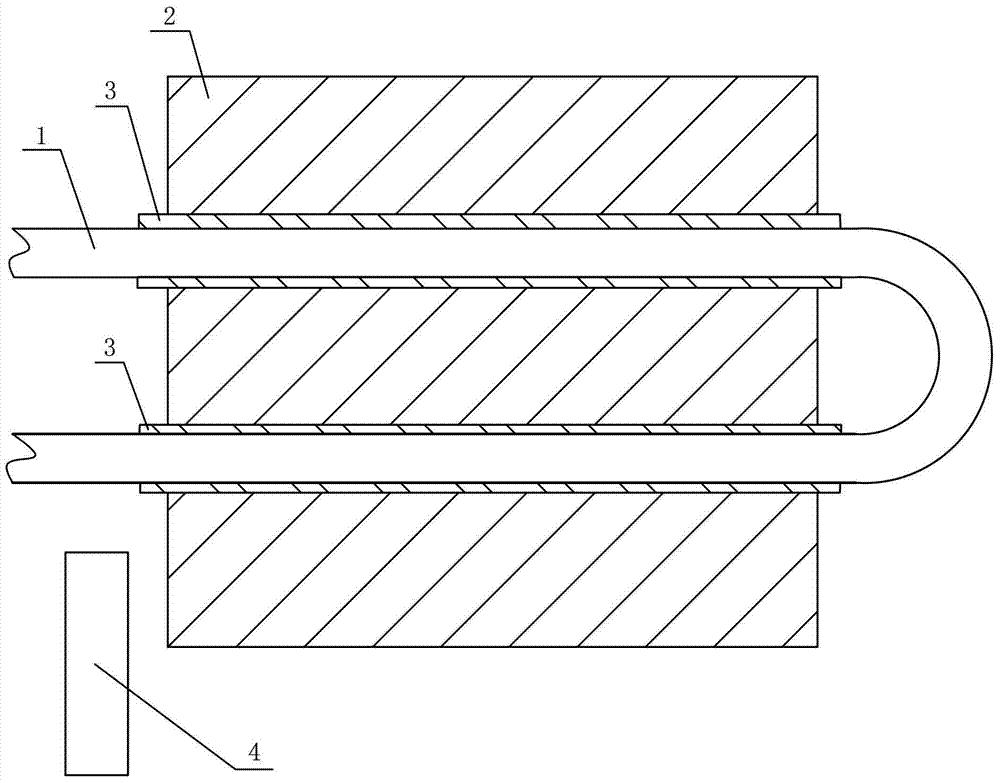

[0019] like figure 1 As shown, the liquid-cooled insulated heat sink of this embodiment includes: a heat-conducting substrate 2, and a substrate through-hole is provided inside the heat-conducting substrate 2, wherein the extending direction of the substrate through-hole is consistent with the extending direction of the heat-conducting substrate 2; Cooling pipe 1, the liquid cooling pipe 1 passes through the through hole of the substrate, the liquid cooling pipe 1 has a liquid inlet end and a liquid outlet end; a thermally conductive insulating material 3 is ringed between the hole wall of the substrate through hole and the liquid cooling pipe 1 to conduct heat The arrangement of the insulating material 3 enables the heat conduction substrate 2 and the liquid cooling pipe 1 to conduct heat and insulate each other.

[0020] In this embodiment, the liquid cooling pipe 1 is configured as a U-shaped pipe; its liquid inlet and outlet ends are located on the same side of the heat co...

Embodiment 2

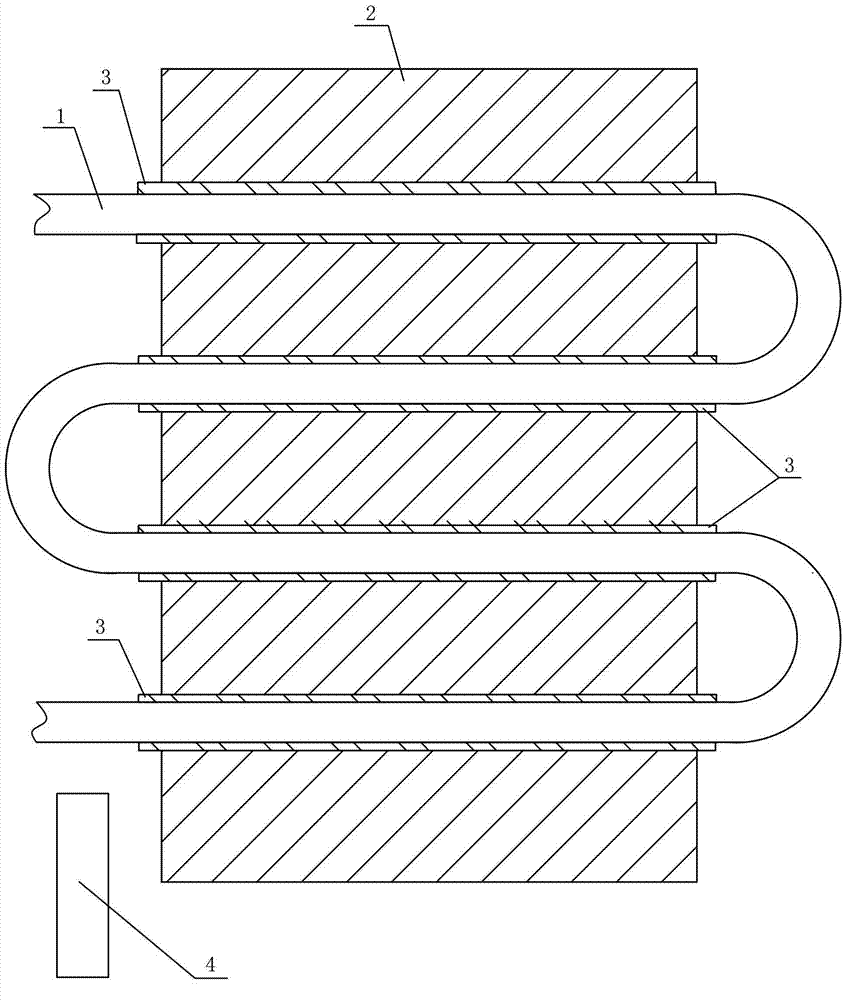

[0024] like figure 1 As shown, the second embodiment is basically the same as the first embodiment, except that the liquid cooling pipe 1 is a coil structure formed by connecting a plurality of U-shaped pipes in series; correspondingly, there are a plurality of substrate through-holes. The liquid cooling tube of the coil structure increases the heat transfer area, which can further improve the heat dissipation effect of the radiator.

[0025] In summary, using the liquid-cooled insulating radiator of the present invention, the heat generated by the power semiconductor device is transferred to the liquid cooling pipe through the heat-conducting substrate and the heat-conducting insulating material, and the heat is taken away by the medium flowing inside the liquid cooling pipe, realizing The purpose of heat dissipation and cooling of power semiconductor devices can meet the requirements of heat dissipation, insulation and small size at the same time, so that the high-voltage el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com