Thin-film transistor, and preparation method, array substrate and display thereof

A technology of thin film transistors and array substrates, applied in the display field, can solve the problems of increasing leakage current, affecting the display quality of the display, affecting the working characteristics of the TFT, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

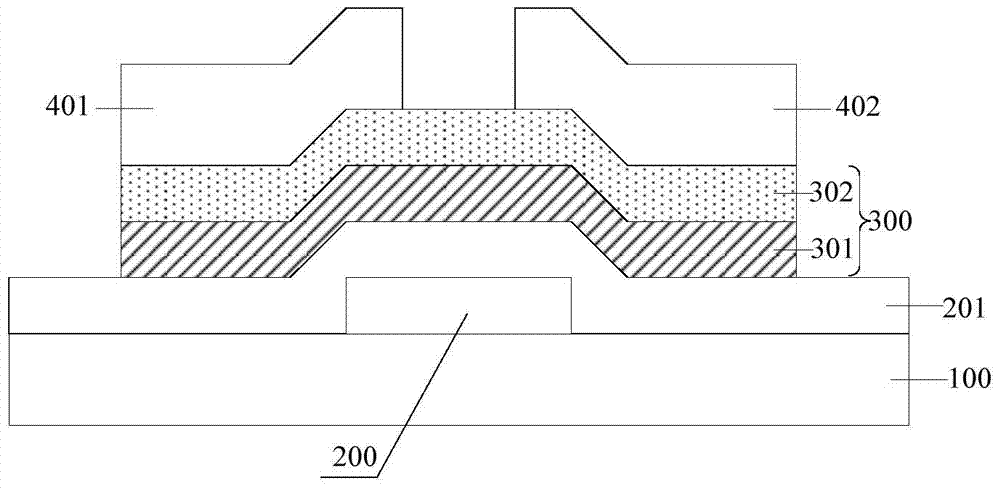

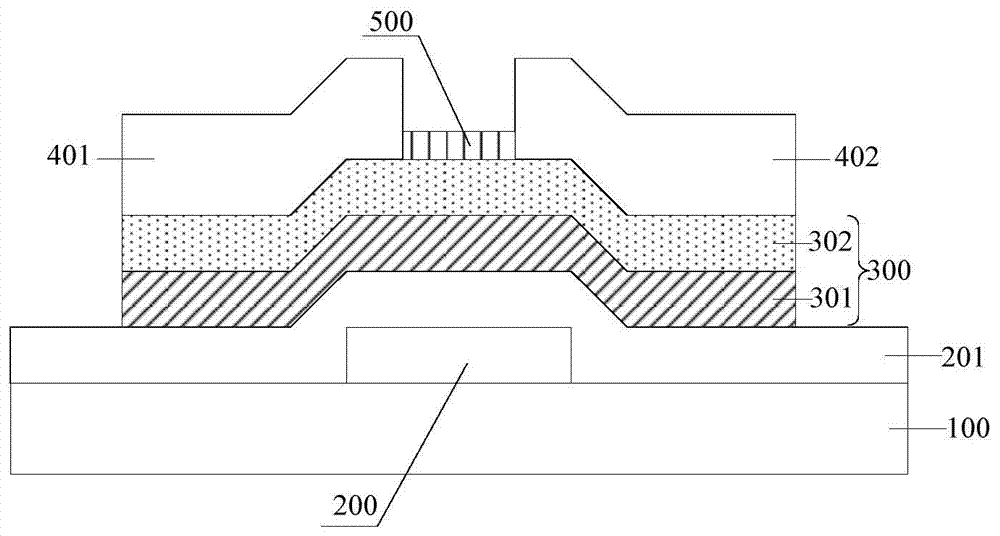

[0057] Embodiment 1. Embodiment 1 of the present invention provides a bottom-gate thin film transistor. Refer to figure 2 As shown, it includes: a gate 200, a gate insulating layer 201, an active layer 300, a source 401 and a drain 402; wherein, the active layer 300 includes a layer of zinc oxide semiconductor first active layer 301 and A second active layer 302 of gallium and aluminum co-doped zinc oxynitride semiconductor, and the first active layer 301 is arranged on the gate insulating layer 201, and the second active layer 302 is arranged on above the first active layer 301; the thin film transistor further includes an etch barrier layer 500, and the etch barrier layer 500 is disposed on the gap corresponding to the gap between the source electrode 401 and the drain electrode 402. above the second active layer 302 .

[0058] Wherein, the thickness of the first active layer 301 of a layer of zinc oxynitride semiconductor is 1.5 times the thickness of the second active la...

Embodiment 2

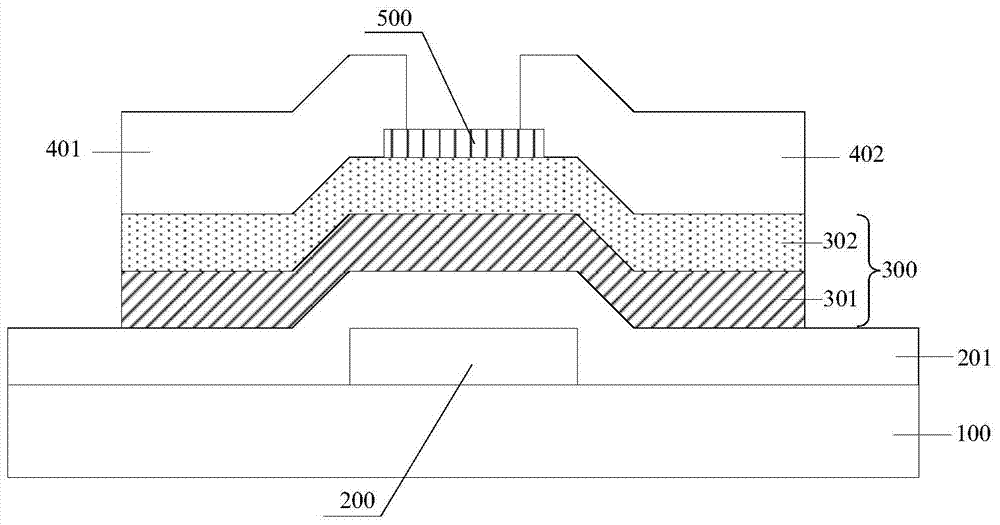

[0061] Embodiment 2. Embodiment 2 of the present invention provides a top-gate thin film transistor. Refer to Figure 4 As shown, it includes: a source electrode 401 and a drain electrode 402, an active layer 300, a gate insulating layer 201, and a gate electrode 200 sequentially arranged on a substrate 100; wherein, the active layer 300 includes a layer of zinc oxynitride semiconductor A first active layer 301 and a second active layer 302 of germanium-doped zinc oxynitride semiconductor, and the second active layer 302 is arranged on the source 401 and the drain 402, the first An active layer 301 is disposed on the second active layer 302 .

[0062] Wherein, the thickness of the first active layer 301 of a layer of zinc oxynitride semiconductor is the same as the thickness of the second active layer 302 of a layer of germanium-doped zinc oxynitride semiconductor; and, the germanium-doped The total concentration is 2.0%.

[0063] Since the material of the second active laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com