Embedding layer heterojunction tunneling field effect transistor and manufacturing method thereof

A technology of tunneling field effect and embedded layer, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc. The effect of large on-state current and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

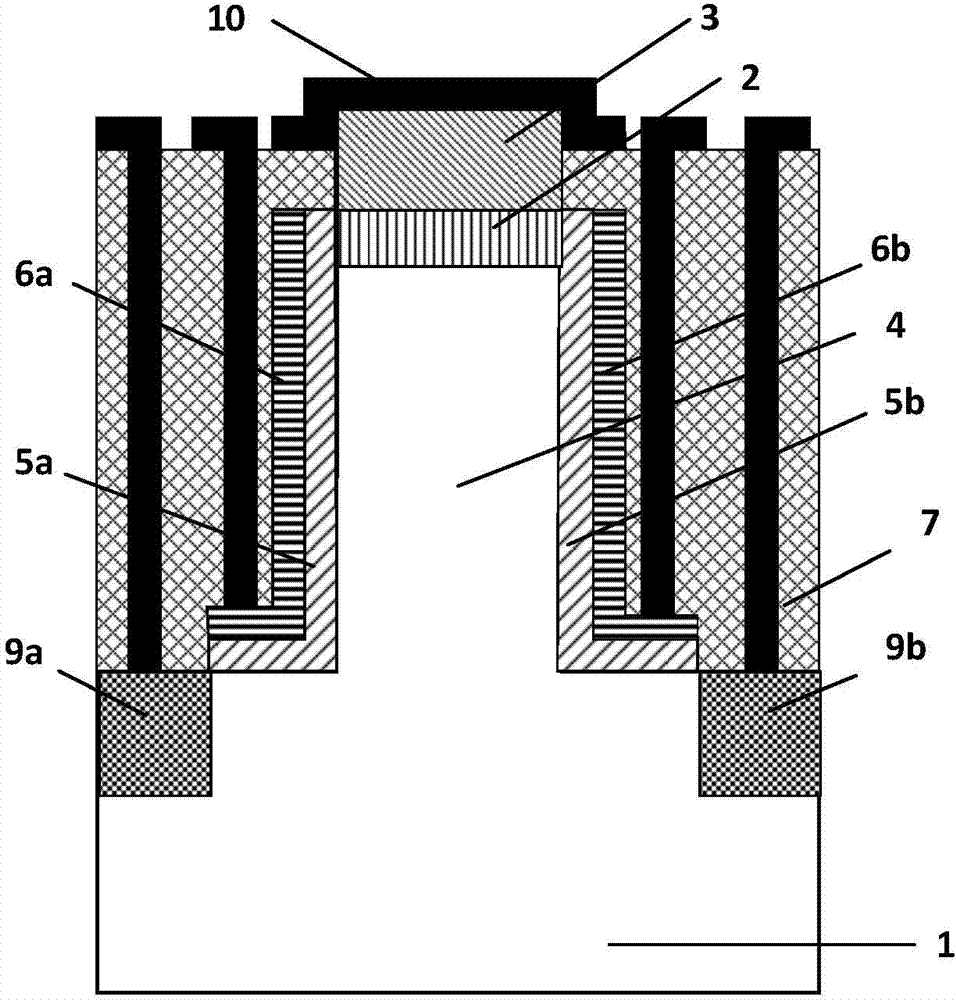

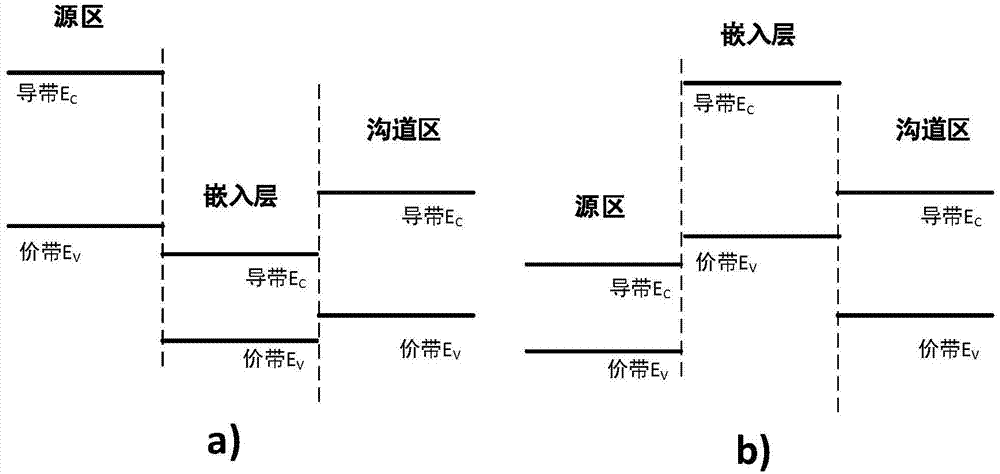

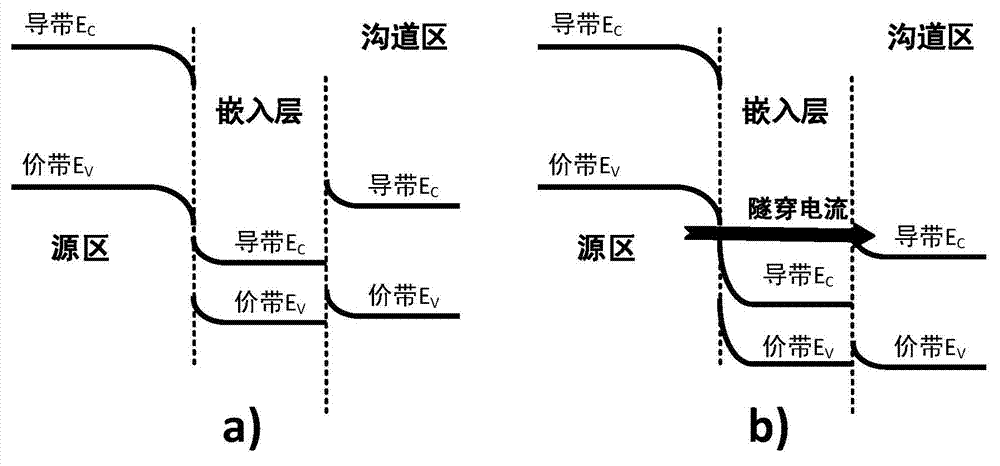

[0050] In this embodiment, the structure of the embedded layer heterojunction tunneling field effect transistor is as follows figure 1 As shown, it includes a semiconductor substrate 1 , a tunneling source region 3 , an embedded layer 2 , a channel region 4 , a drain region 9 , and a gate dielectric layer 5 and a control gate 6 located on both sides of the channel region. It is characterized in that the device has a vertical channel, and the double control gates on both sides of the vertical channel are L-shaped structures. Moreover, there is a hetero-inlaid layer 2 between the tunneling source region and the channel region. Among them, a staggered heterojunction (Broken-Gap) is formed at the interface between the tunneling source region and the embedded layer, and a staggered heterojunction (Staggered-Gap) is formed at the interface betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com