Angle position error detecting and compensating device of round angle position sensor and compensating method

A technology of error detection and compensation device, applied in the direction of electronic commutator, etc., to achieve the effect of improving angle measurement accuracy and system performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

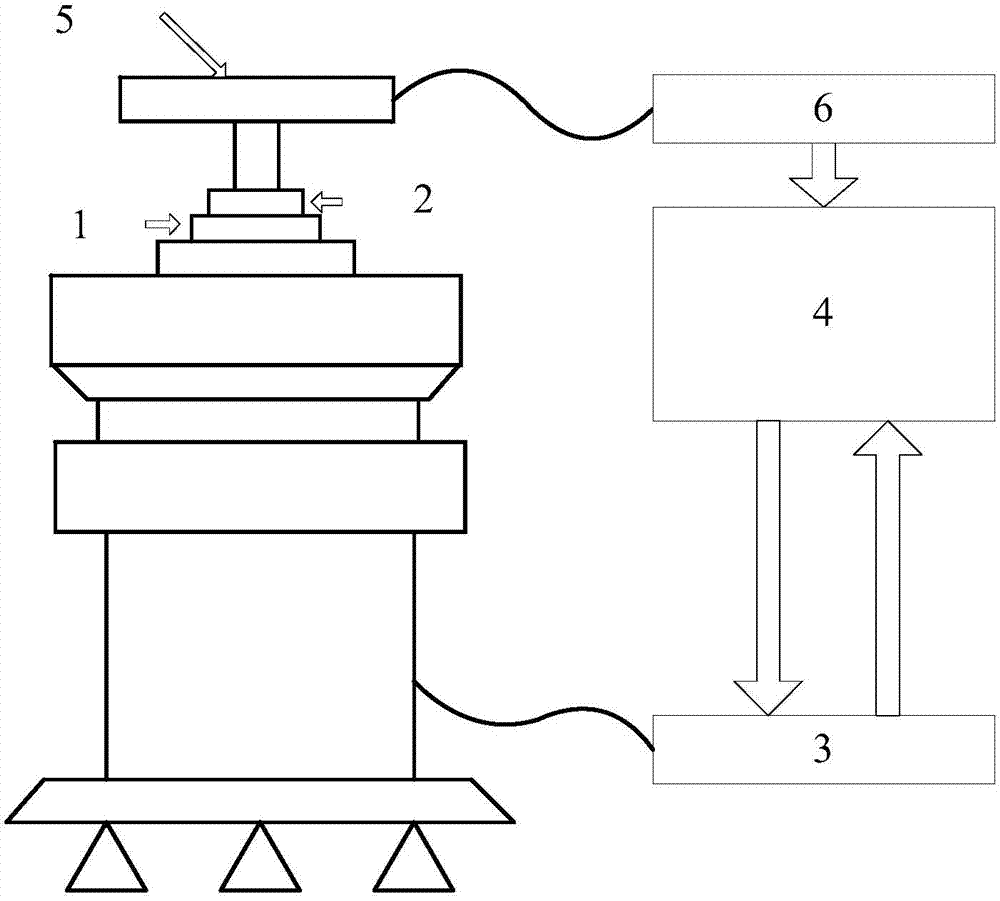

[0030] According to the content of the invention, this embodiment constructs a circular angular position sensor angular position error detection and error compensation device, as shown in the attached figure 1 shown. The specific parameters and design of each part are as follows:

[0031] Photoelectric encoder 1: Reinshaw’s incremental photoelectric code disk circular grating is RESM2U-SA550, the read head is T2600-3M, the subdivision head is TI0400A12A, the diameter is 550mm, and the system accuracy is 1”;

[0032] Permanent magnet synchronous motor 2: RBE02110B AC permanent magnet synchronous motor from kollmorgen company is used, the continuous stall torque is 0.952Nm, the peak torque is 2.55Nm, and the mass is 0.585kg;

[0033] Turntable control module 3: use the DSP chip (TMS320F2812) and FPGA chip to form the core control module, control the rotation of the permanent magnet synchronous motor 2, and forward the angular position data of the photoelectric encoder to the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com