Glass-cleaning robot

A glass-cleaning robot and body technology, applied in vacuum cleaners, cleaning equipment, household appliances, etc., can solve the problems of easy dislocation, unusable machines, inconvenient use, etc., and achieve strong controllability, flexible movement, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

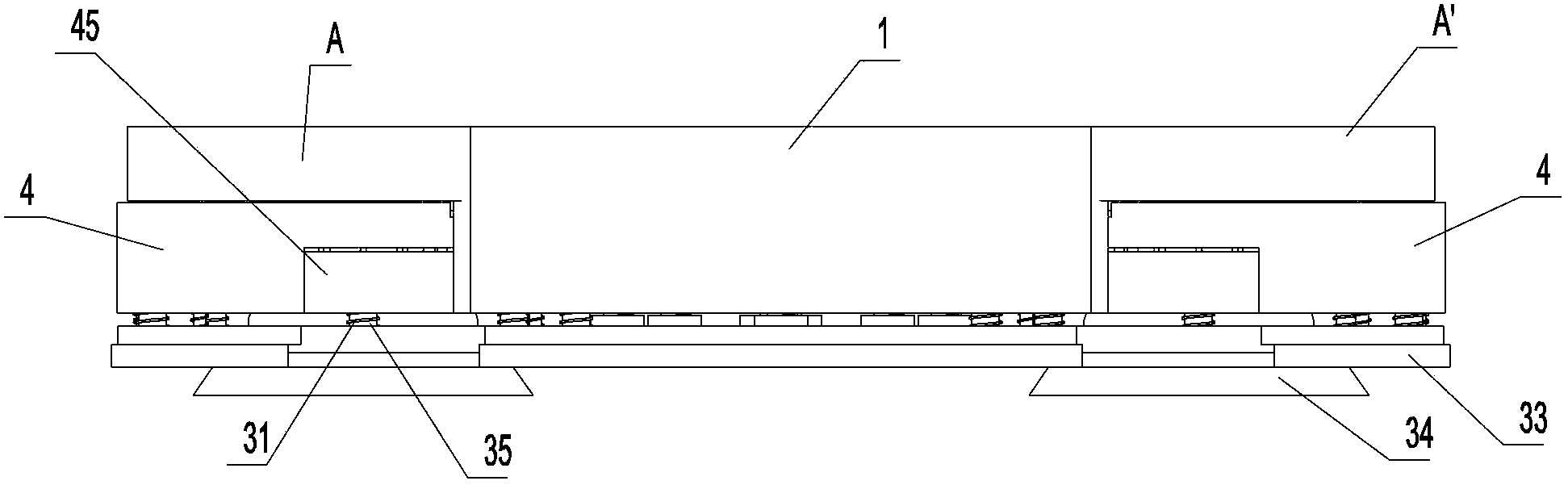

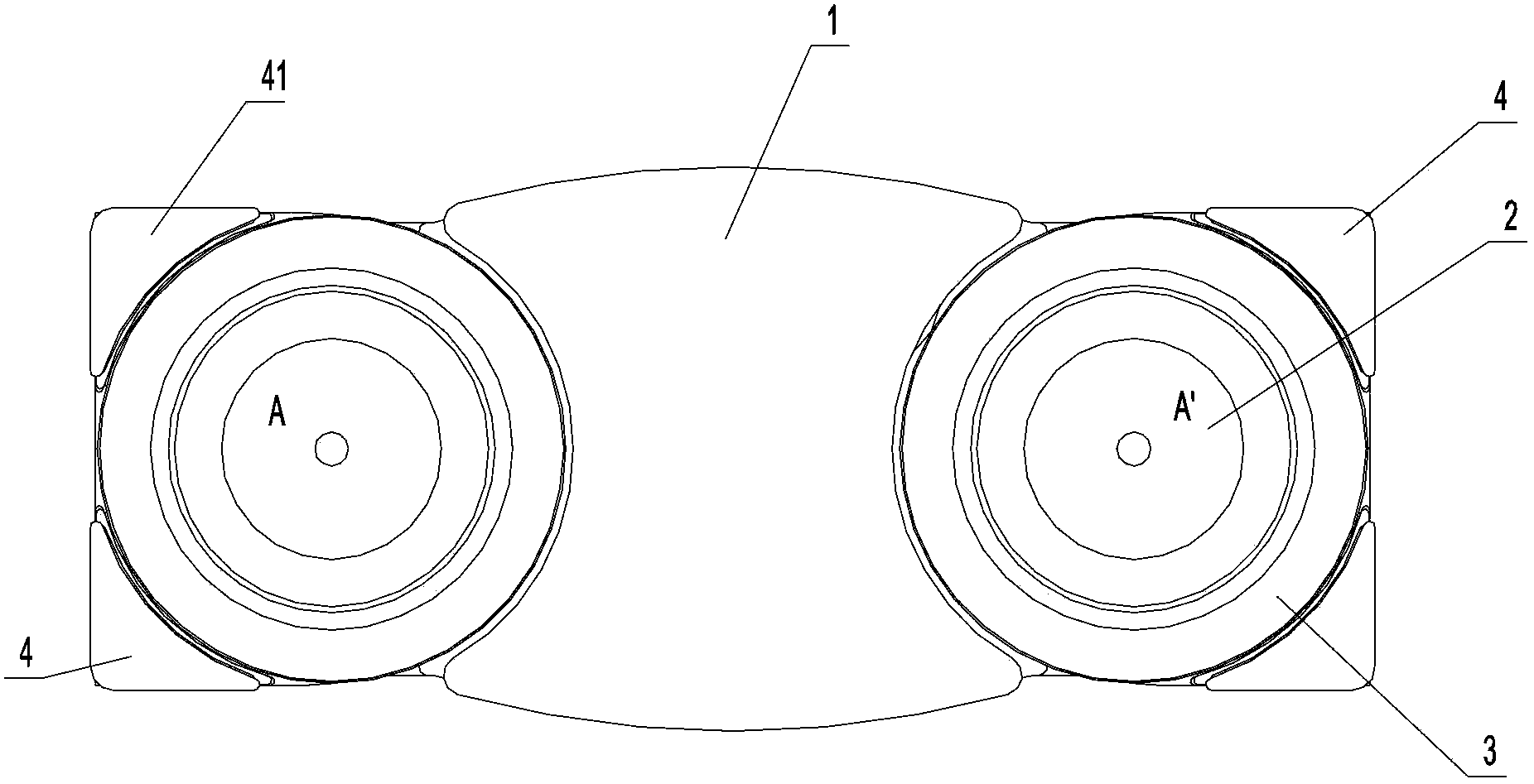

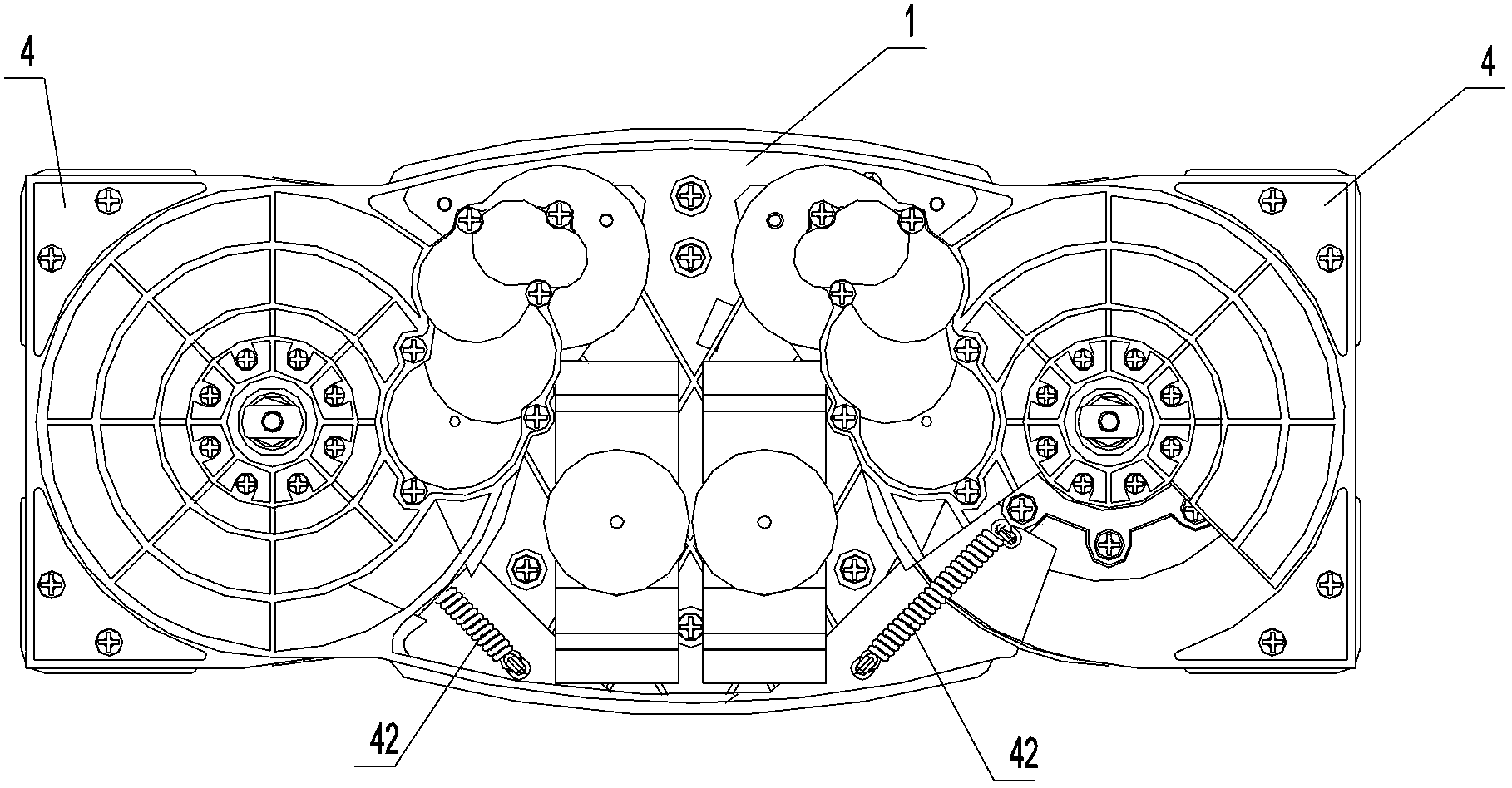

[0023] figure 1 It is a schematic diagram of the overall structure of the present invention; figure 2 for figure 1 bottom view of image 3 for figure 1 top view of Figure 4 It is a schematic diagram of the local structure of the present invention; Figure 5 for Figure 4 sectional view. combine Figure 1 to Figure 5 As shown, the present invention provides a glass-wiping robot, including a body 1 on which a control unit, a drive unit (not shown) and a first cleaning unit 2 are provided, and the glass-wiping robot also includes a rotatable A pair of adsorption turntables 3 at both ends of the bottom of the body 1, the drive unit is connected with the adsorption turntables 3 through a control unit, and the control unit controls the magnitude and direction of power output on the two adsorption turntables 3 respectively, and drives the pair of adsorption turntables 3 The adsorption turntable 3 rotates or is stationary around the vertical axis perpendicular to the glass s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com