High temperature resistant nano emulsion and low energy consumption preparation method thereof

A technology of nanoemulsion and high temperature resistance, which is applied in the field of nanoemulsion and its low-energy preparation. It can solve the problems of lowering the phase transition temperature and failing to increase the charge capacity of negatively charged nanoemulsions, and achieves adjustable charges, low equipment prices, and energy saving. The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

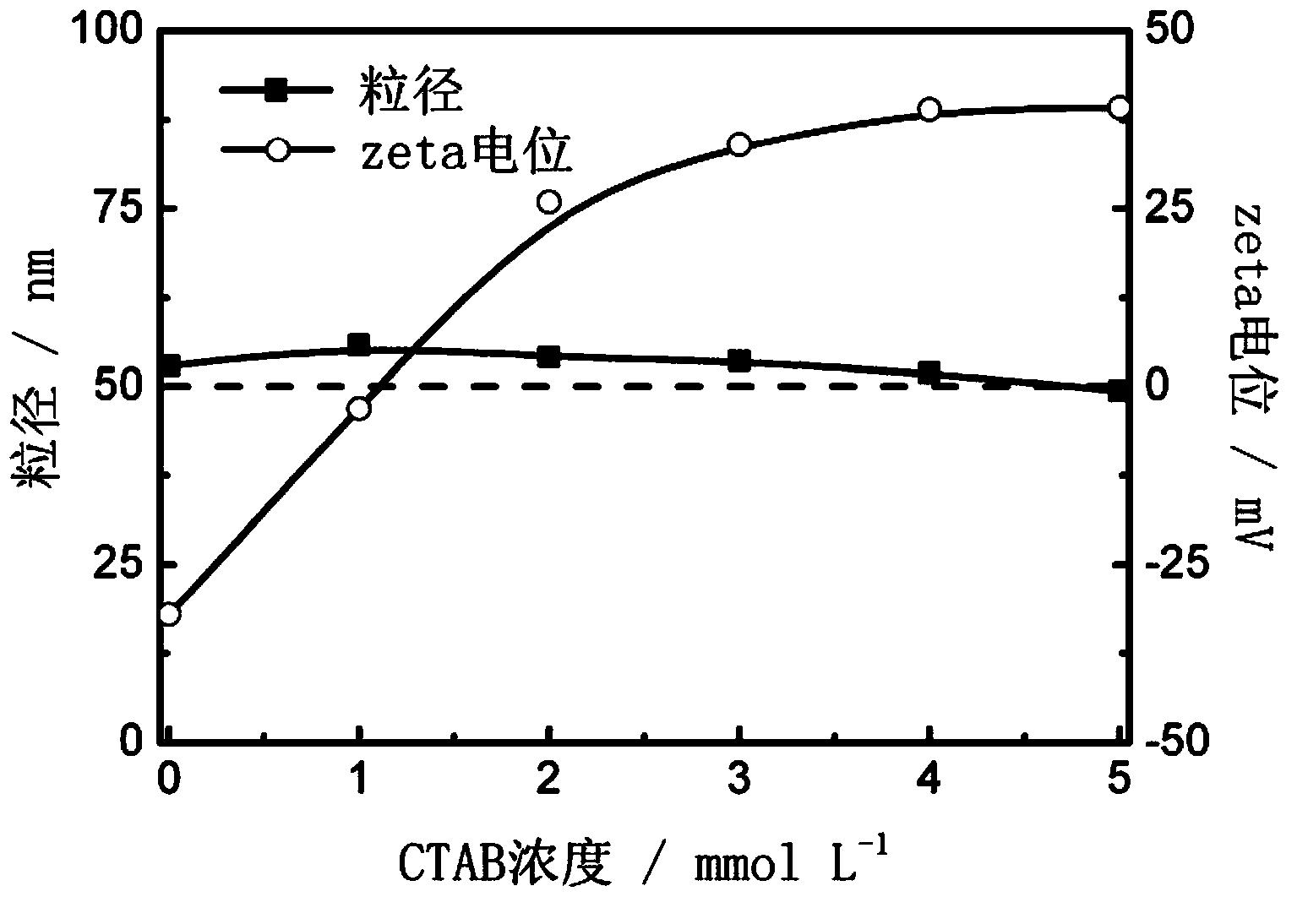

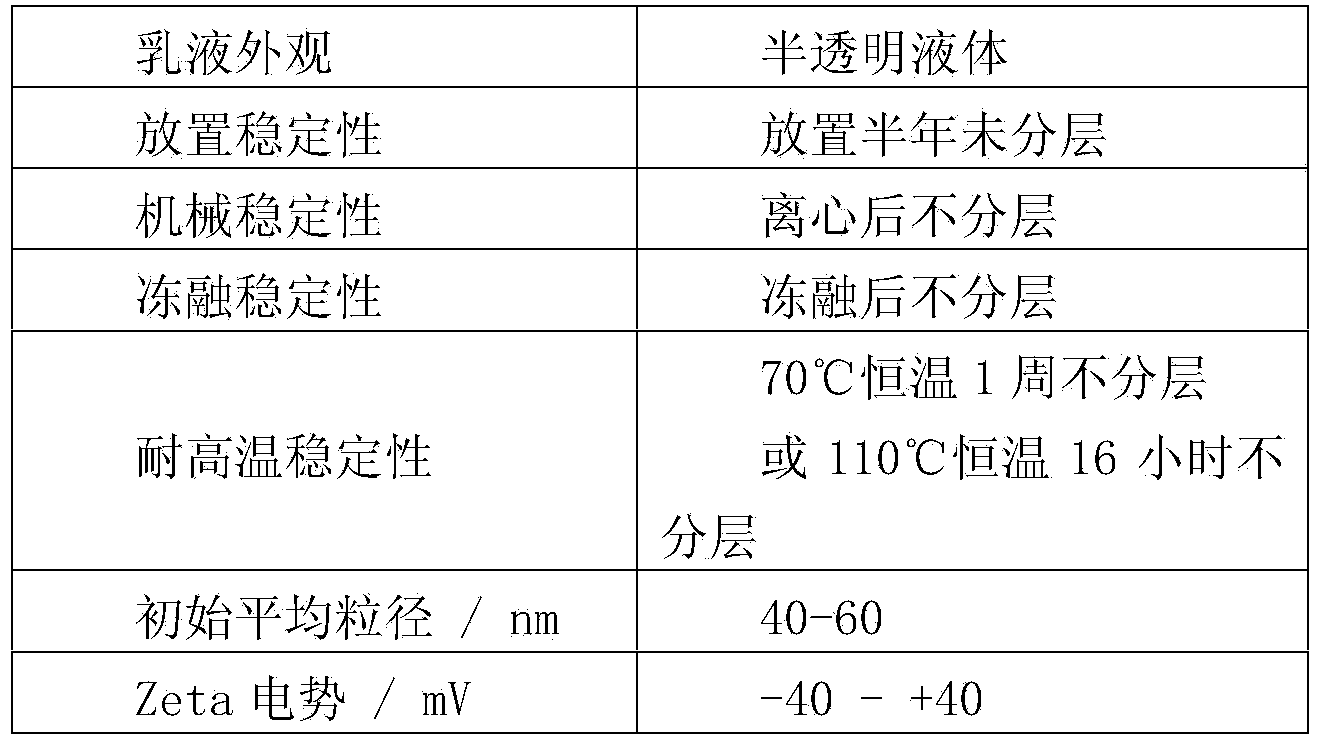

[0021] Prepare a high-temperature-resistant positively charged nanoemulsion with an average particle size of 40-60nm and a zeta potential of -40mV-+40mV. The following components are weighed in 100 parts by weight: 10 parts of liquid paraffin, 10 parts of nonionic surfactant (combination of 5.6 parts of Tween20 and 4.4 parts of Span20), 0.2 parts of cationic surfactant CTAB, and 79.8 parts of water.

[0022] Mix 0.2 parts of CTAB, 5.6 parts of Tween20, 4.4 parts of Span20 and 10 parts of liquid paraffin to prepare a surfactant oil solution, and heat it to 80°C under stirring at a speed of 400rpm; heat water to 80°C in another reactor ℃, within 10 minutes (minutes), add water dropwise to the oil solution of the surfactant, stop stirring and transfer the reactor from the water bath to room temperature to cool down to obtain a high temperature resistant positively charged nanoemulsion.

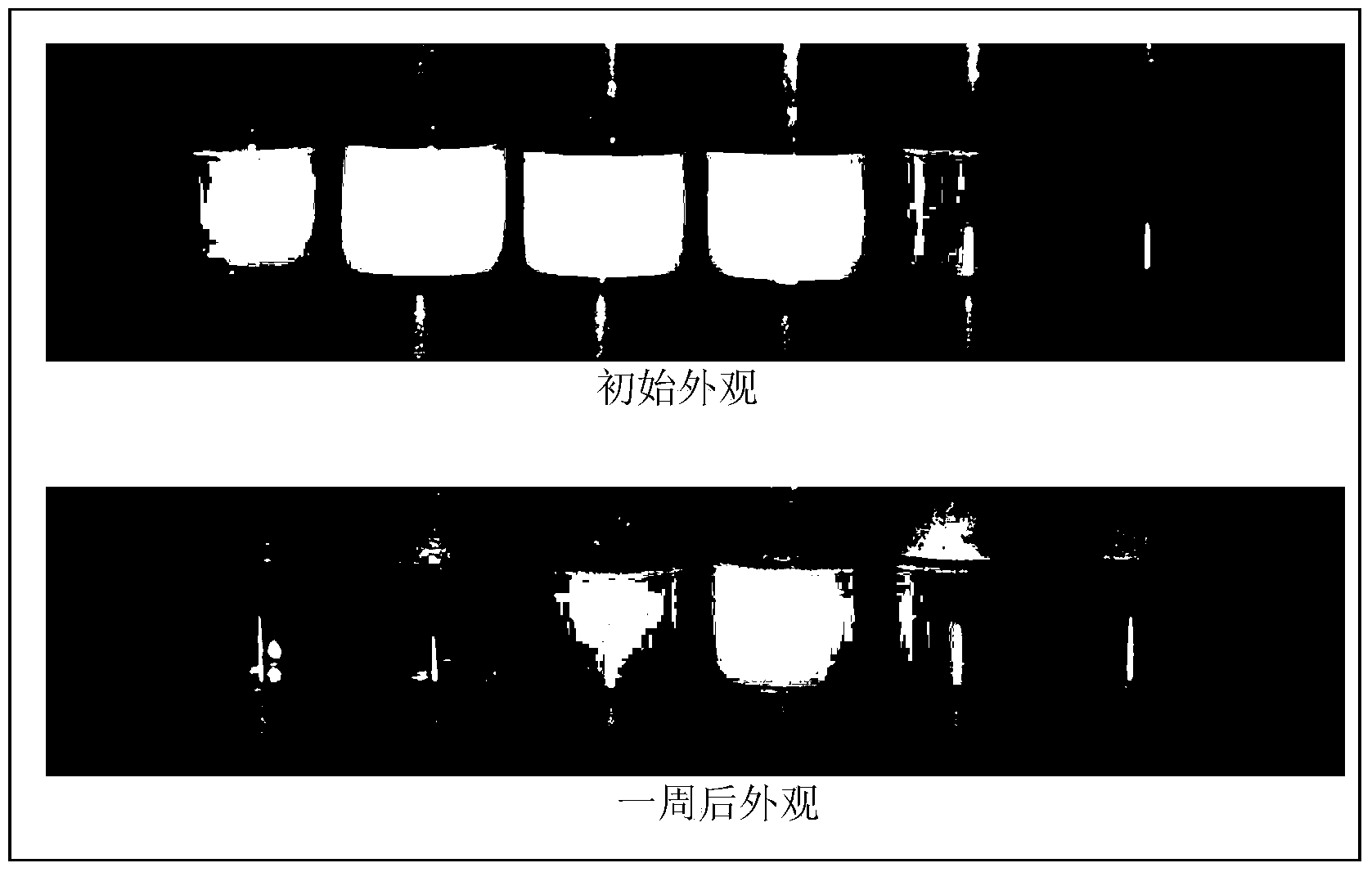

[0023] The stability, mechanical stability, freeze-thaw stability and high temperature stabil...

Embodiment 2

[0036] Prepare a high-temperature-resistant positively charged nanoemulsion with an average particle size of 100-250nm and a zeta potential of +15mV-+50mV. The following components are weighed in 100 parts by weight: 25 parts of liquid paraffin, 10 parts of nonionic surfactant ( Combination of 6.2 parts of Brij30 and 3.8 parts of Span85), 0.1 part of cationic surfactant STAB, 64.9 parts of water.

[0037] According to the preparation method described in Example 1, the high-temperature-resistant positively charged nanoemulsion of the present embodiment is prepared, and the experimental data of its properties are shown in the following table:

[0038]

Embodiment 3

[0040] The preparation average particle size is at 40-100nm, and zeta potential is the high temperature resistant negative charge nanoemulsion of-37mV--50mV, with 100 parts by weight, takes by weighing 20 parts of white oil, 20 parts of nonionic surfactants (11 parts of Tween60 and A combination of 9 parts of Span60), 0.5 parts of anionic surfactant SDS, and 59.5 parts of water.

[0041] Prepare the high-temperature-resistant negatively charged nanoemulsion of the present embodiment according to the preparation method described in Example 1, and the experimental data of its properties are shown in the following table:

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com