Multi-purpose food slicer

A slicer, multi-purpose technology, applied in metal processing and other directions, can solve the problems of operator labor, sticking knife, easy sticking knife, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

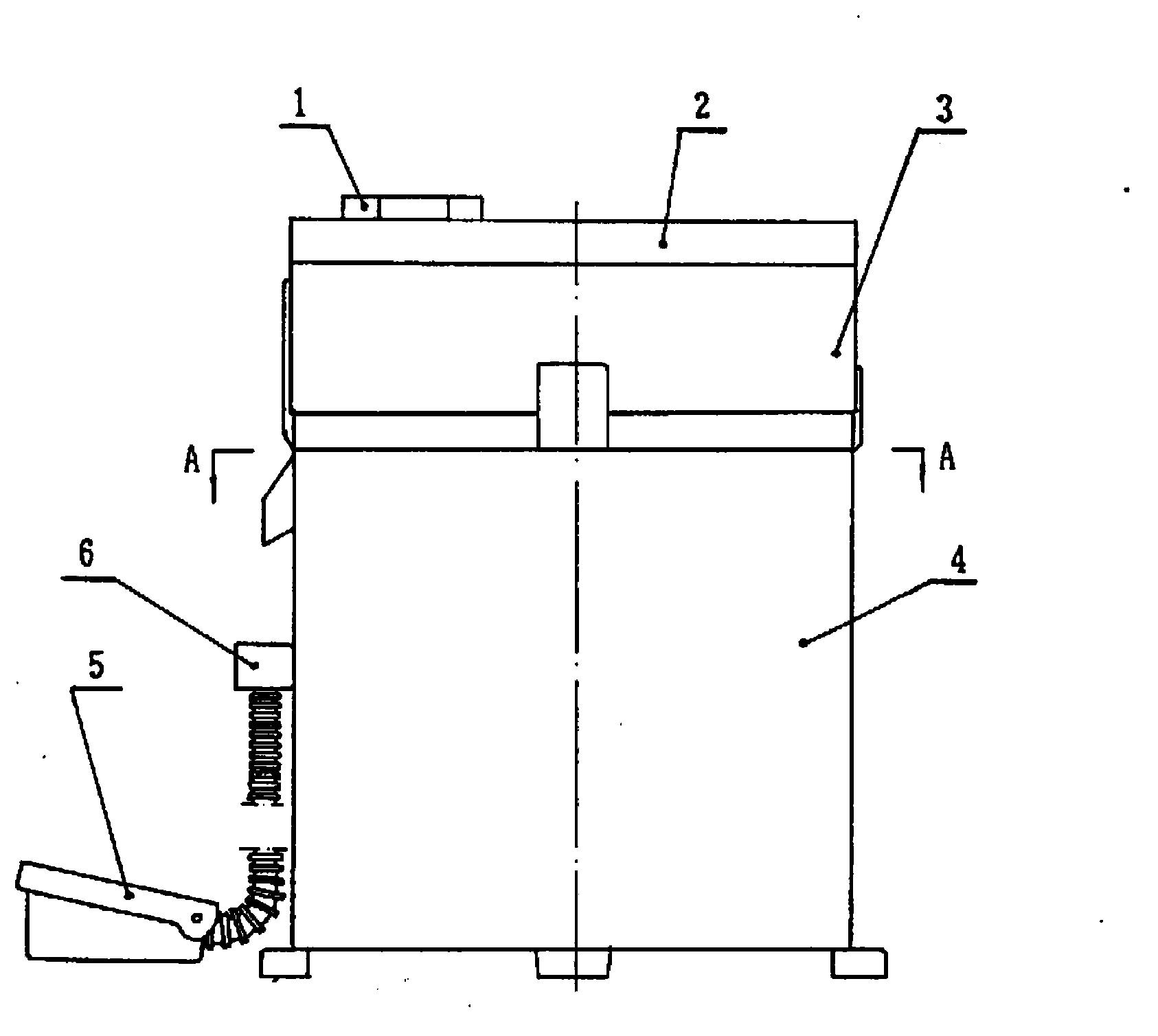

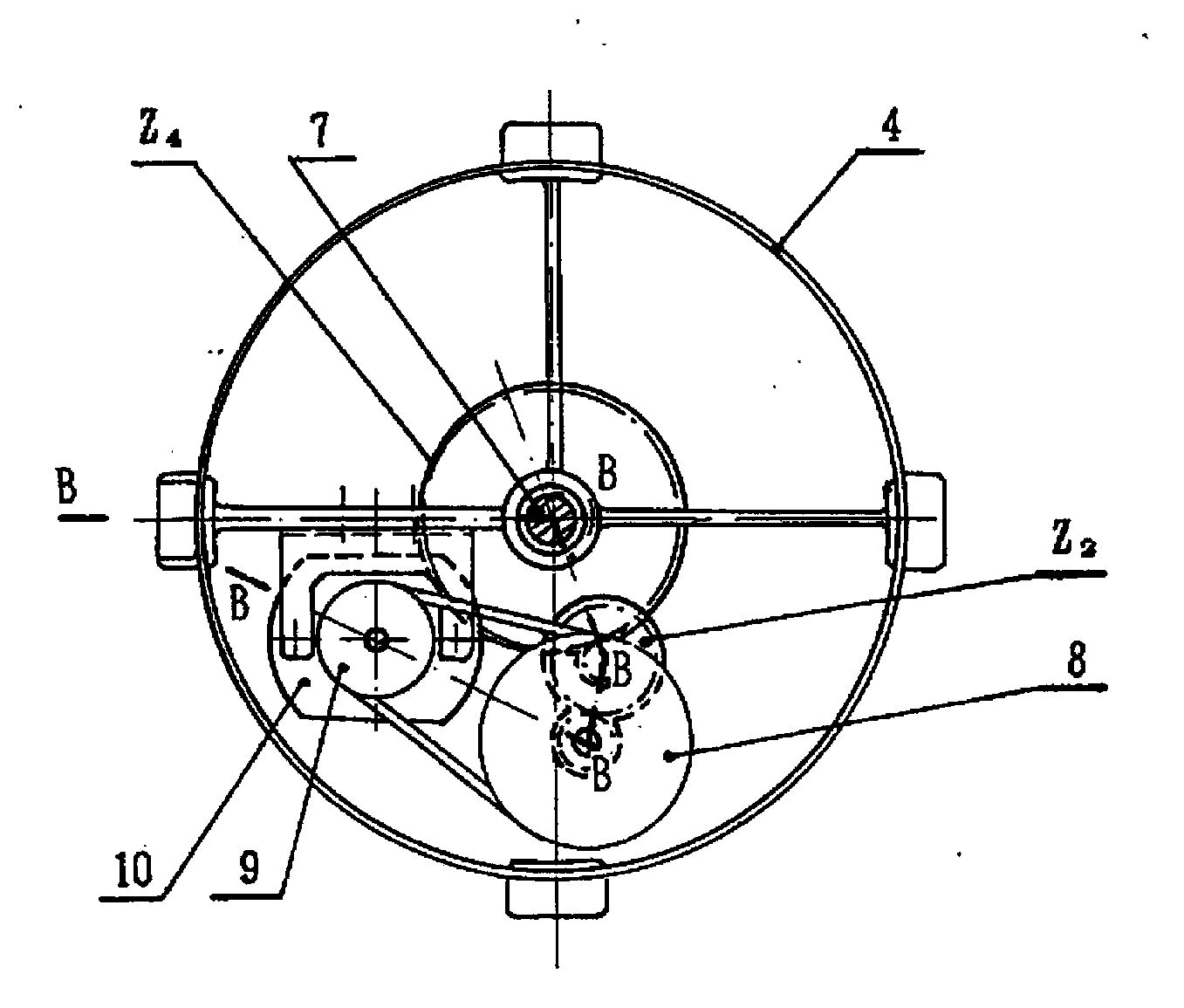

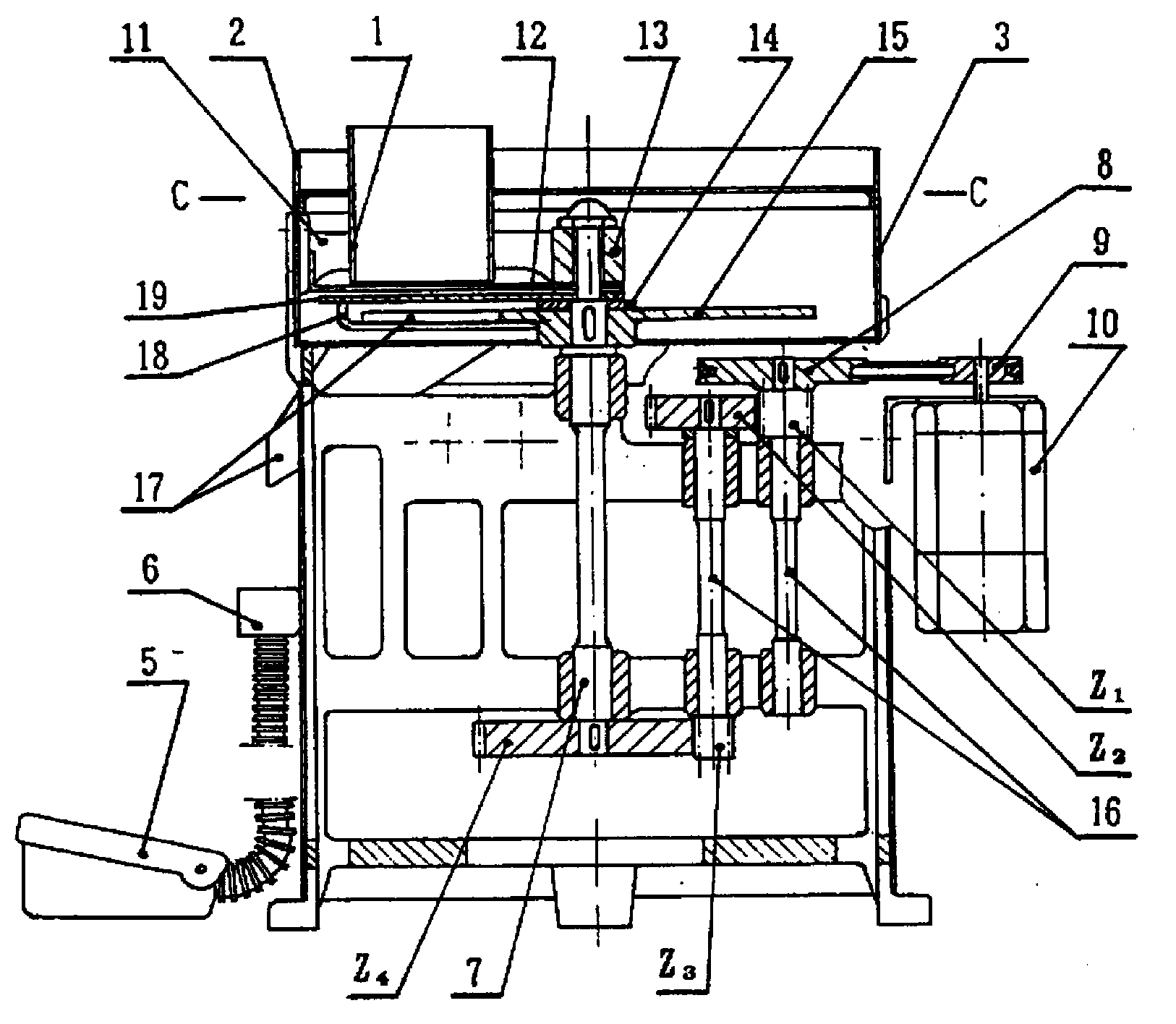

[0007] The present invention will be further described below in conjunction with accompanying drawing: Multipurpose food slicer (see Figure 1-4 ) consists of a power transmission mechanism and a shear mechanism. The power transmission mechanism includes a motor (10) inside the frame (4), which drives the main shaft (7) to rotate after being decelerated by a three-stage reduction mechanism. The reduction mechanism includes the small pulley (9) on the output shaft of the motor, which is transmitted to the large pulley (8) via a flat belt, the gears on the two transmission shafts (16) supported in the gear bearings in the frame, and the gears on the main shaft. Power input to drive the spindle to rotate. A socket (6) for connecting the motor activated by a foot switch (5) is provided between the motor and the power supply. The shearing mechanism includes a feeder tray (3) fixed to the frame, inside the feeder tray there is a knife disc (15) which is keyed to the main shaft an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com