Oil-soluble molybdenum dialkyldithiocarbamate additive preparation method

A dialkyl dithiocarbamic acid and molybdenum additive technology, applied in additives, chemical instruments and methods, petroleum industry, etc., can solve the problem that the product does not have oil solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

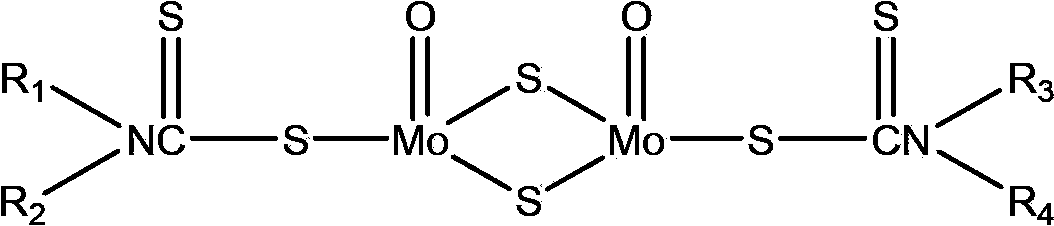

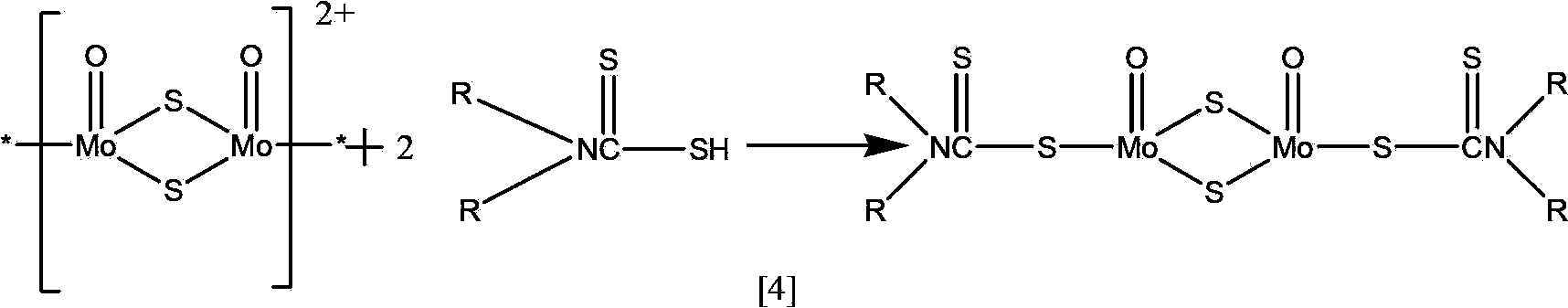

Method used

Image

Examples

Embodiment 1

[0031] Example 1: In a 500ml reaction flask, add 14.4g of molybdenum trioxide to an aqueous solution containing 38 grams of sodium sulfide, stir at room temperature until completely dissolved, add 80g of Karamay minus second-line naphthenic oil and dropwise add 20 grams of 35% sulfuric acid After completion, add 32.9g of N,N'-di-n-octyldithiocarbamate, heat up to 80°C, react for 4h, filter, wash with water, and distill under reduced pressure to obtain 124.8g of dark brown liquid.

Embodiment 2

[0032] Example 2: In a 500ml reaction flask, add 14.4g of molybdenum trioxide to an aqueous solution containing 28 grams of sodium sulfide, stir at room temperature until completely dissolved, add 80g of Karamay minus three-line naphthenic oil and dropwise add 20 grams of 35% sulfuric acid After completion, 32.9g of N,N'-diisooctyldithiocarbamate was added, heated to 80°C, reacted for 4h, filtered, washed with water, and distilled under reduced pressure to obtain 122.1g of tan liquid.

Embodiment 3

[0033] Example 3: In a 500ml reaction bottle, add 14.4g of molybdenum trioxide to an aqueous solution containing 28 grams of sodium sulfide, stir at room temperature until completely dissolved, add 40g of Karamay minus second-line naphthenic oil, and then add 40g of Karamay minus three-line cycloalkane Add 20 grams of 35% sulfuric acid dropwise to alkane oil, and then add 32.9 g of N,N'-diisooctyldithiocarbamate, heat up to 80°C, react for 4 hours, filter, wash with water, and distill under reduced pressure to obtain brown Brown liquid 121.8g.

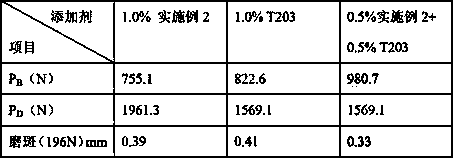

[0034] All target compounds are purified by column chromatography. The Mo and S elemental analysis results of the target compounds are shown in Table 1. From the elemental analysis results in Table 1, it can be seen that the measured values of C, H, and N elements of all target compounds are consistent with the molecular formula The calculated theoretical values are basically consistent, and the absolute error is within the allowab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com