Novel directly buried thermal insulation pipe

A direct-buried thermal insulation pipe, a new type of technology, applied in the direction of thermal insulation, protection of pipes and pipes through thermal insulation, etc., can solve the problem that the thermal insulation effect and production efficiency and the qualified rate of finished products cannot be well guaranteed, the heat loss is large, and the thermal insulation pipe works. Short life and other problems, to ensure the thermal insulation effect and production efficiency and the qualified rate of finished products, avoid heat energy, and reduce the effect of voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

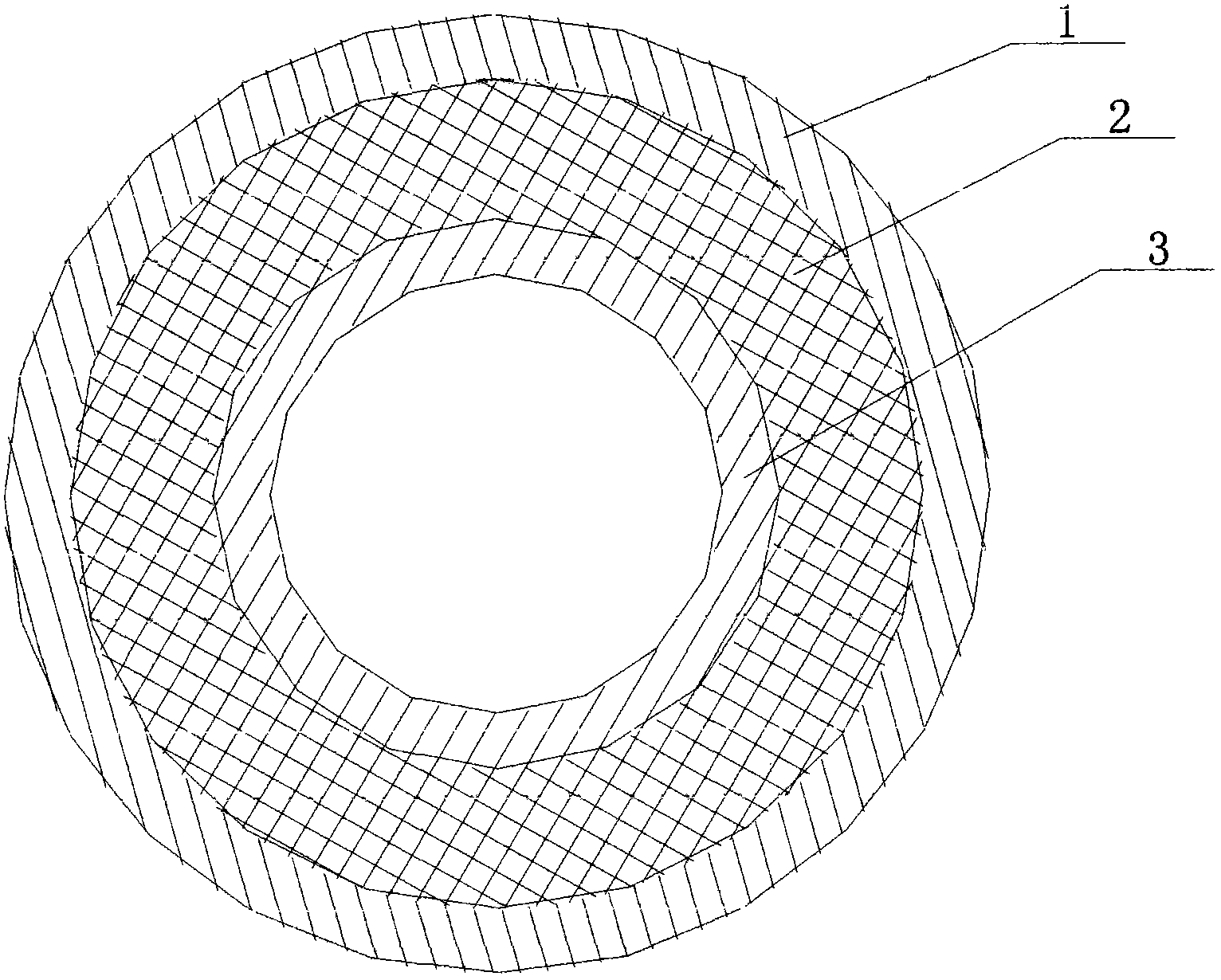

[0009] see figure 1 , The present embodiment adopts the following technical solutions: it includes an outer protective pipe 1, an insulating layer 2, and a working steel pipe 3;

[0010] The outer protective tube 1 is a polyethylene outer protective tube.

[0011] The production process of this specific embodiment is: upper tube transmission line of working steel pipe—feeding machine—combined head—outer protective tube forming—foaming—computer automatic deviation correction—lower pipe transmission line—broken pipe—naked head repair—finished product inspection .

[0012] This specific implementation mode can effectively avoid the heat energy lost by the heat bridge during the operation of the pipe network, better ensure the heat preservation effect, production efficiency and finished product qualification rate, uniform foam, reduce the void of the pipe insulation layer, reduce heat loss, and maximize The efficient use of heat energy improves the working life of the insulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com