Performance control system of oxygen-deficit protection device suitable for various flue gas types and gas pressures

A hypoxia protection device and control system technology, which is applied in the field of safety protection systems, can solve problems such as failure to reach, difficult to ignite, and yellow flames, and achieve the effects of simplifying types and specifications, reducing component processing, and broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

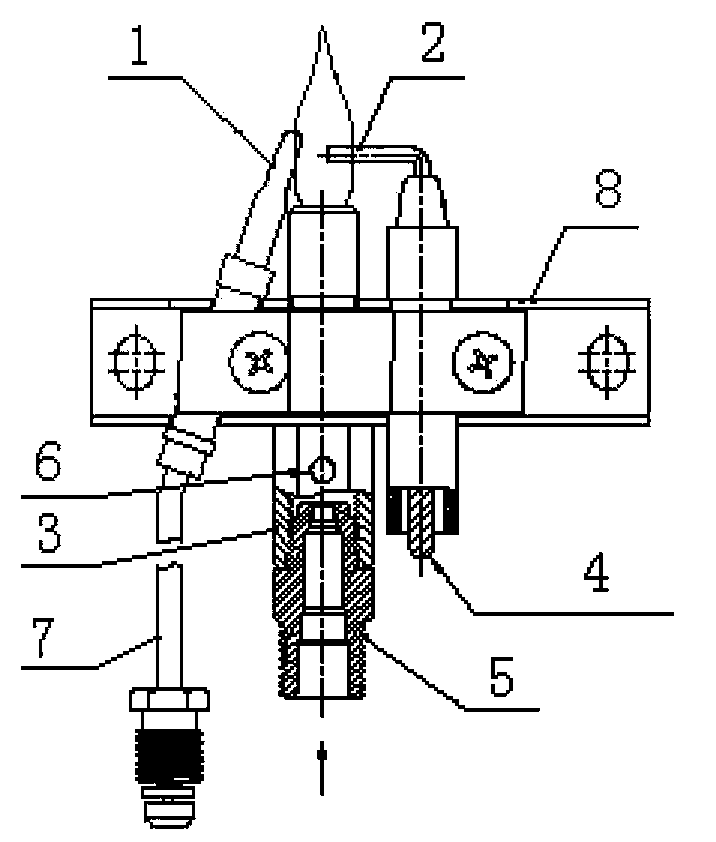

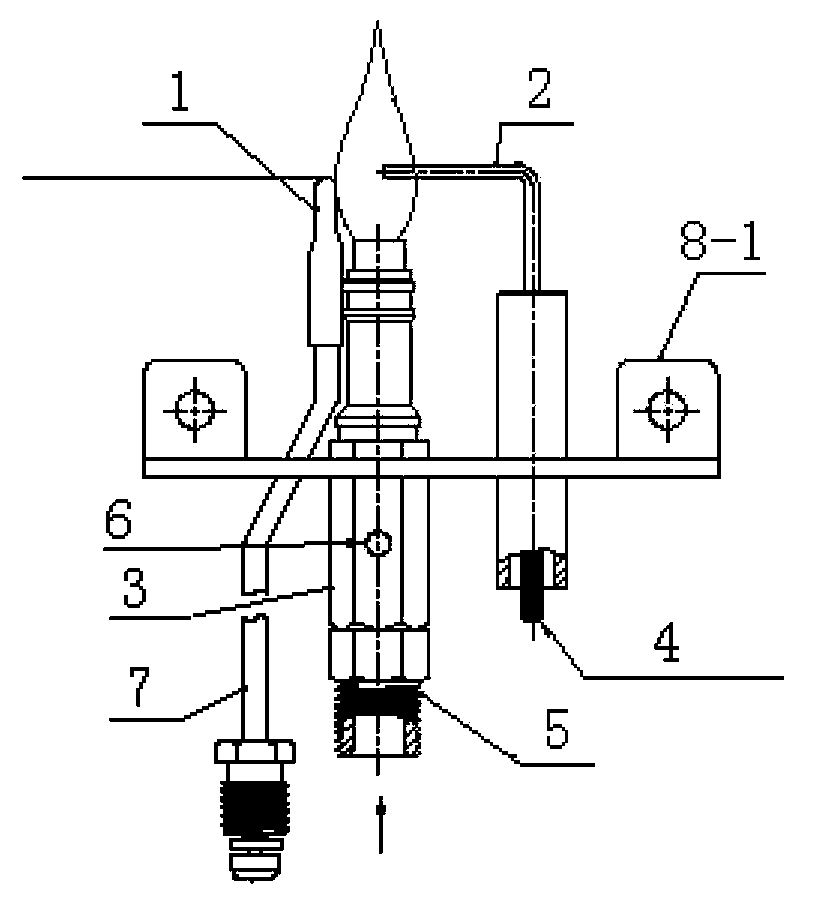

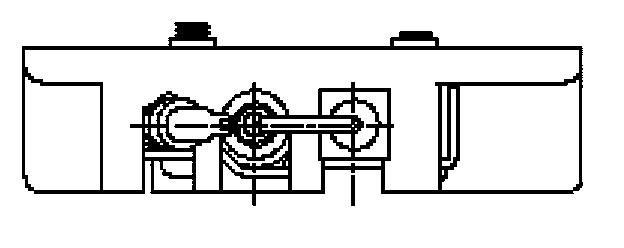

[0040] See Figure 1-1 to Figure 9 , The performance control system of an oxygen-deficient protection device suitable for multiple gas types and air pressures of the present invention is composed of a mounting frame, an ejector tube, a thermocouple, and an ignition needle. The ejector tube, thermocouple, and ignition needle are respectively fixed On the mounting frame, the ejector tube is provided with internal threads and threaded steps, the internal threads are connected with the nozzle below, and the first mixing channel for the first mixing of gas and external air is provided on the step above the threads, and the step has Two symmetrical air holes, the hole diameter is 2.6±0.2mm, and a second mixing channel with a smaller inner diameter than the first mixing channel is provided above the first mixing channel. The gas nozzle is provided with two s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com