Preparation method of hydrate deposit sample

A hydrate sediment and sample preparation technology, applied in the field of hydrate sediment research, can solve the problems of long period and poor representation, achieve the effect of short period and promote natural balanced distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a novel method for preparing hydrate sediment samples. The method is to provide a certain temperature gradient or salinity gradient or a combination of the two methods along the sample height direction during the preparation of the hydrate sediment sample, so that the hydrate is gradually and uniformly formed in the sediment pores.

[0022] Specifically, the present invention includes two steps:

[0023] 1. Inject natural gas from one end of the sediment sample, wherein the salt content of the sediment sample from the inlet end to the gas outlet end has a gradient from high to low, and / or, the temperature of the sediment sample from the inlet end to the gas outlet end varies from high to low. Low has a gradient, so that the sediment samples at the gas outlet first form hydrates, and then gradually extend to the sediment samples at the inlet to form hydrates;

[0024] 2. After the sediment samples at the inlet end form hydrates, the sediment sampl...

Embodiment 1

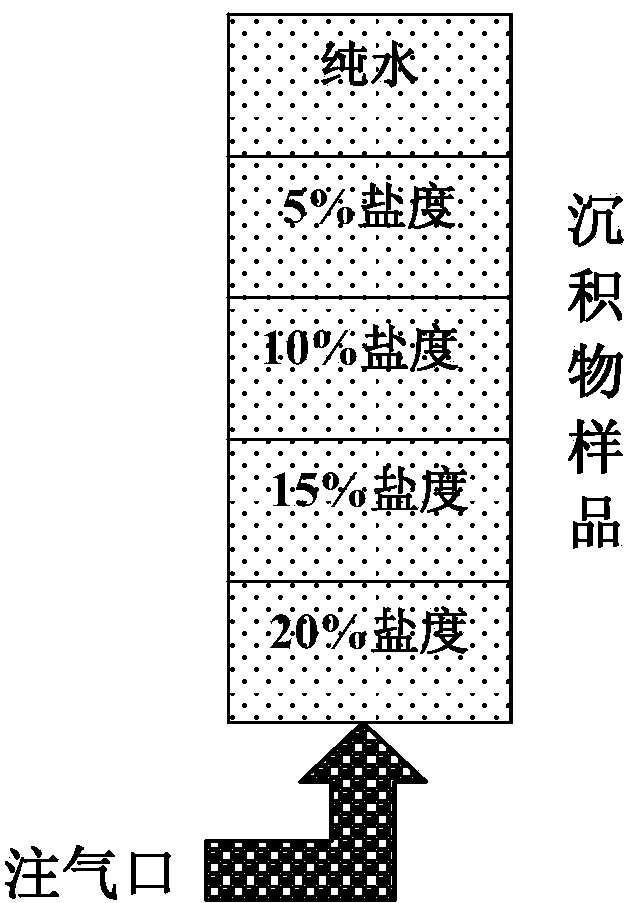

[0027] Embodiment one, adopt salinity gradient mode

[0028] like figure 1 As shown, for the sample preparation method of hydrate-containing sediments with controlled salinity gradient, taking soil mechanics triaxial sample preparation as an example, first prepare N parts of aqueous solutions with different salinities, and N is an integer greater than 2. Taking N equal to 5 as an example, the salinity of the preparation solution is 0%, 5%, 10%, 15%, and 20% respectively; then the aqueous solution is mixed with the test soil, and then divided into 5 layers according to the order of solution concentration from large to small Crush into a sample; then inject a certain pressure of methane gas from the bottom of the sediment sample (at the inlet end, with a salinity of 20%), and maintain the temperature, pressure and salinity conditions so that the sediment pores containing pure water are the first to form Hydrate.

[0029] The synthesis process is as follows: for example, referr...

Embodiment 2

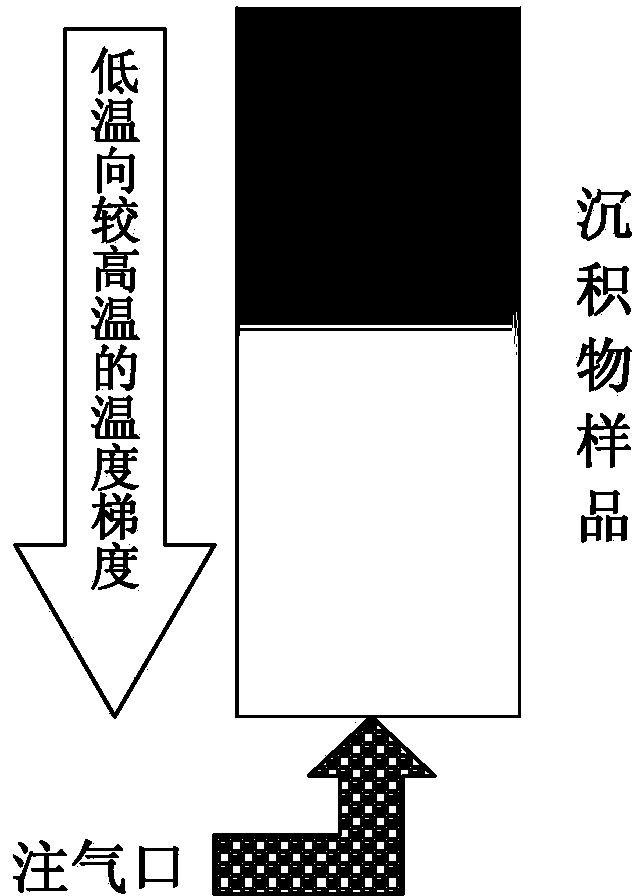

[0032] Embodiment two, adopt temperature gradient mode

[0033] like figure 2 As shown, for the sample preparation method of hydrate-containing sediments with controlled temperature gradient, taking the preparation of soil mechanics triaxial samples as an example, the sediment samples are first compacted according to a certain water content; Methane gas at a certain pressure, maintaining temperature and pressure conditions can make hydrates first form in the top sediment pores, that is to say, the top (gas outlet) temperature is lower, and the bottom (intake end) temperature is higher.

[0034] The synthesis process is as follows: For example, referring to Table 1, when the gas pressure is 4.3MPa, assuming that the sample length is L, the temperature at the 1 / 5 point from the top of the sample is controlled to be 4°C, and the temperature in the 0-1 / 5L section is lower than this value, 1 / If the 5L-4 / 5L section is higher than this value, then the hydrate in the 0-1 / 5L section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com