Gross-volume monitoring sensing device for corrosion states and temperature field states of reinforcing steel bars in concrete

A technology of steel bar corrosion and sensing devices, which is applied to measuring devices, thermometers, and thermometers with physical/chemical changes. Self-compensation, to achieve the effect of rust state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

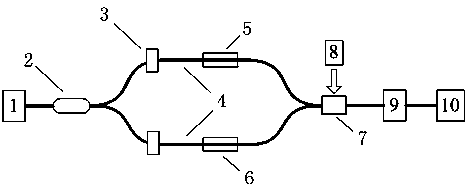

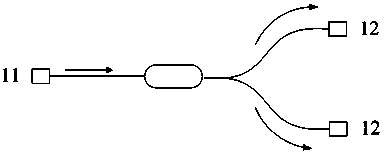

[0045] Depend on Figure 1-3 It can be seen that the full-volume monitoring sensor device for steel bar corrosion state and temperature field state in concrete includes broadband light source, Y-shaped optical fiber coupler, coupler joint, sensing optical fiber, LPFG steel bar corrosion sensing probe, LPFG temperature sensing probe, Optical switch, spectrometer and computer; broadband light source (using LG150 broadband light source) enters the input end of the Y-type optical fiber coupler, propagates to the output end of the Y-type optical fiber coupler, and then propagates to the The LPFG steel bar corrosion sensing probe and the LPFG temperature sensing probe interact with the measured environment in the tested environment to generate a coupling effect between the fiber core and the cladding, and then form a corresponding detection optical pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com