Mass pruduction method for manufacturing chip resistor

A technology of metal sheets and resistors, applied in non-adjustable metal resistors, trimming resistors, resistors, etc., can solve problems such as insufficient product accuracy, increased cost, and poor structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

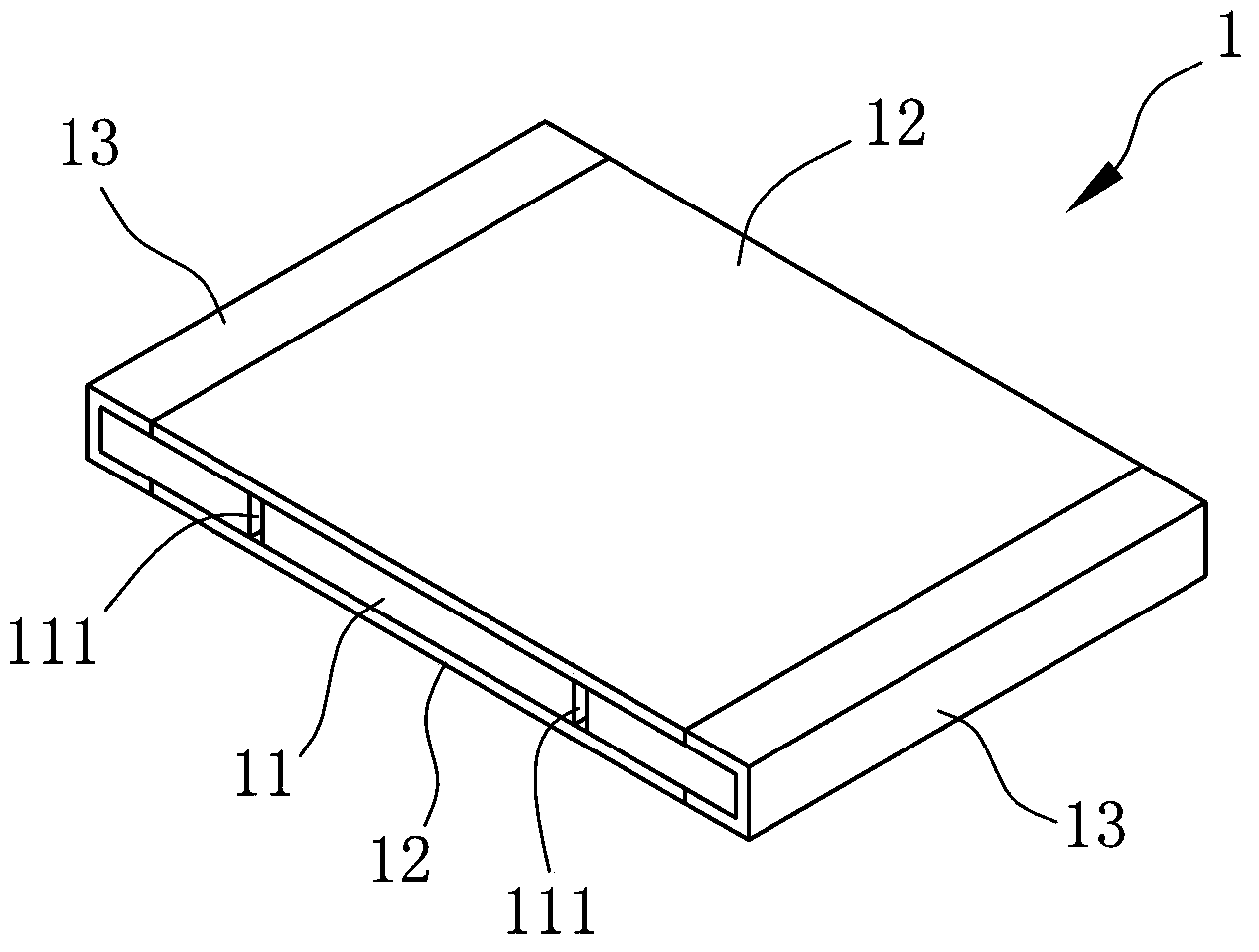

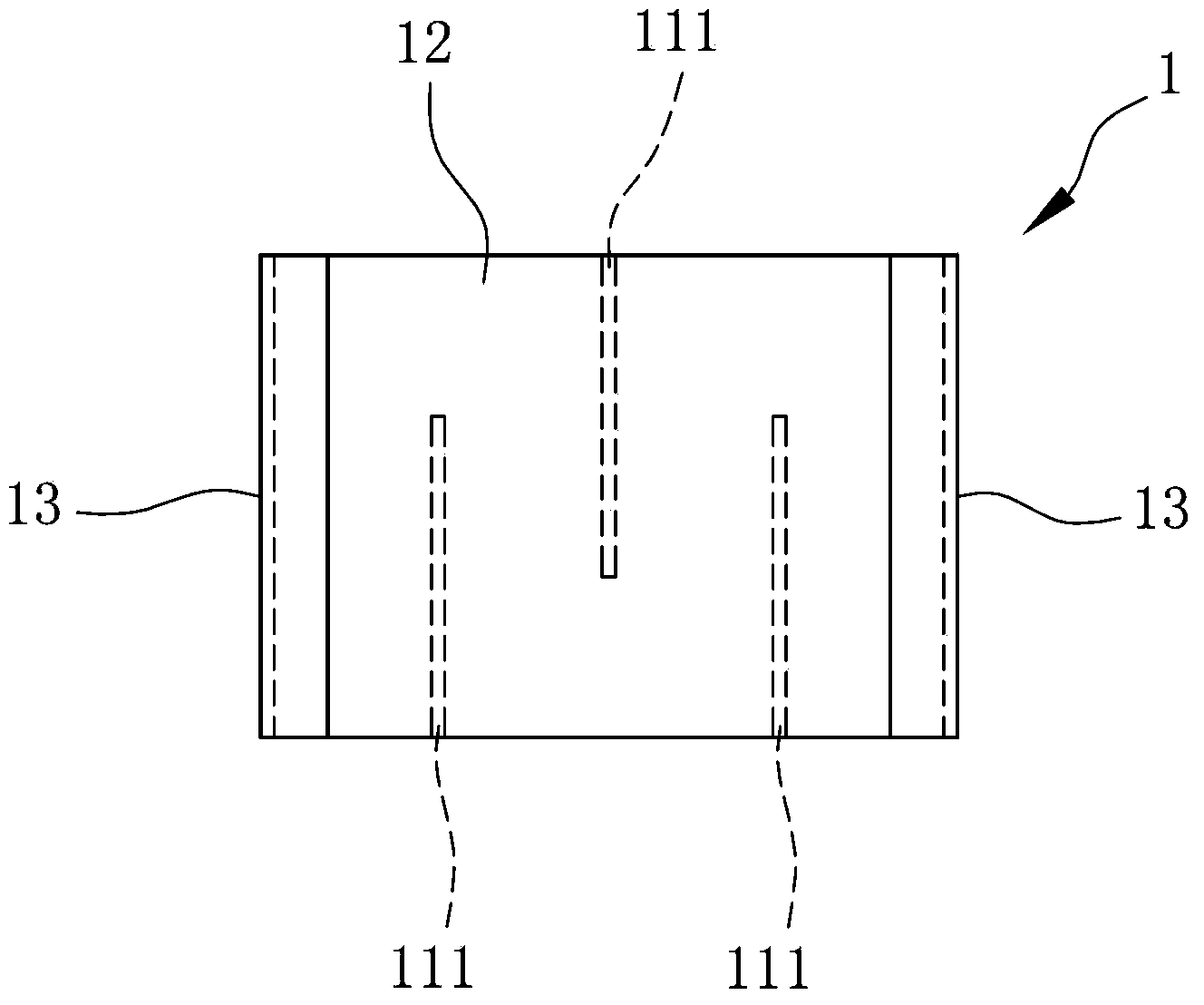

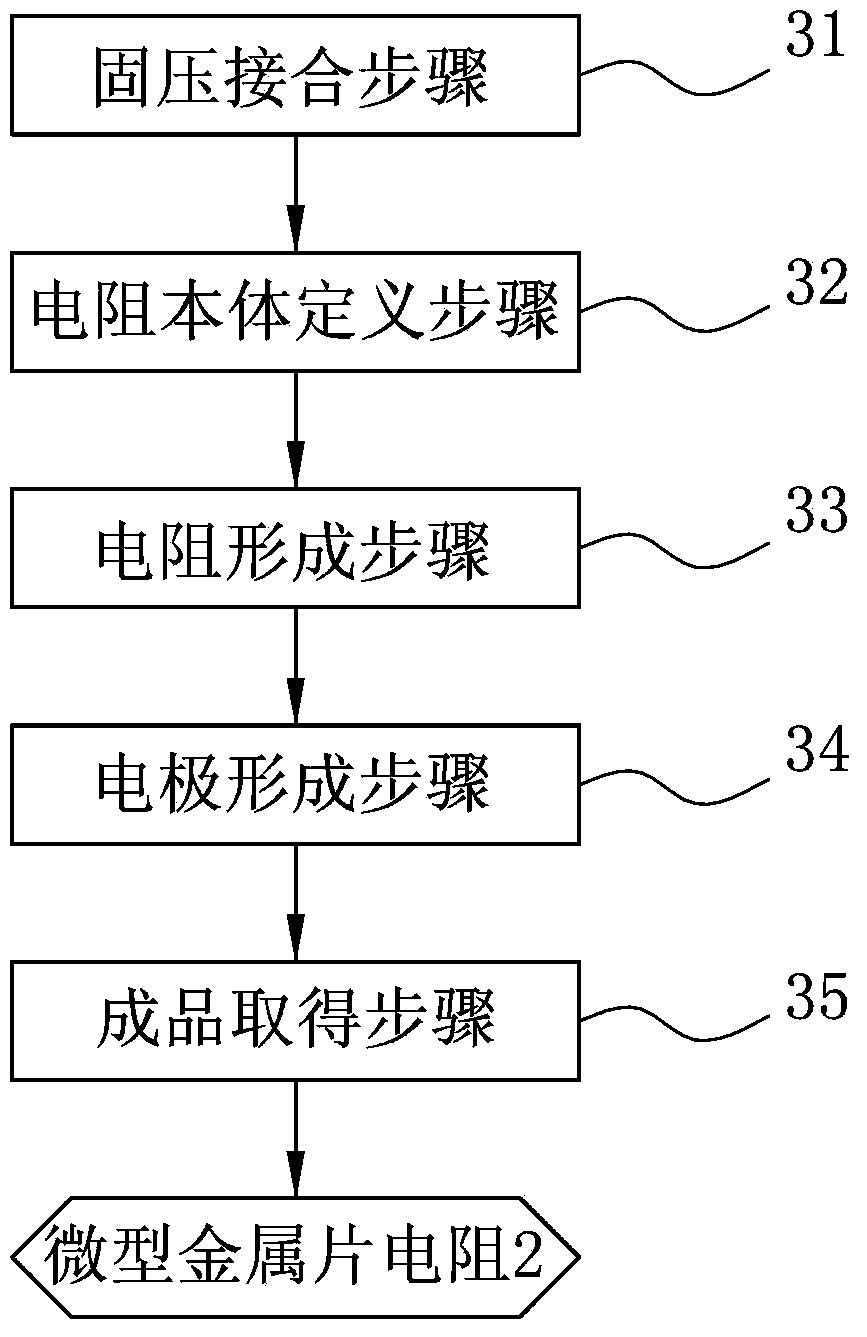

[0037] refer to image 3 , Figure 4 , a preferred embodiment of the mass production method of a micro-metal sheet resistor of the present invention, comprising a pressure-fixed bonding step 31, a resistor body definition step 32, a resistor forming step 33, an electrode forming step 34, and a finished product Obtain step 35, and can mass-produce such as Figure 4 miniature metal sheet resistors 2.

[0038] see first Figure 4 , and refer to Figure 5 , Image 6 The miniature metal sheet resistor 2 produced by the preferred embodiment of the mass production method of the miniature metal sheet resistor of the present invention includes a resistor body 21, a layer of isolation layer 22, a layer of heat dissipation layer 23, and two electrodes 24, which can be Provides precise resistance in use.

[0039] The resistor body 21 is sheet-shaped and ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com