Cutting blade

A grinding wheel, three-dimensional technology, applied in the direction of bonded grinding wheels, abrasives, metal processing equipment, etc., can solve the problems of reduced dimensional accuracy, inability to obtain cutting performance, etc., to improve wear resistance and cutting performance, and suppress the generation of burrs , Improve the effect of cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0065] Next, the effects of the present invention will be described with reference to more specific examples.

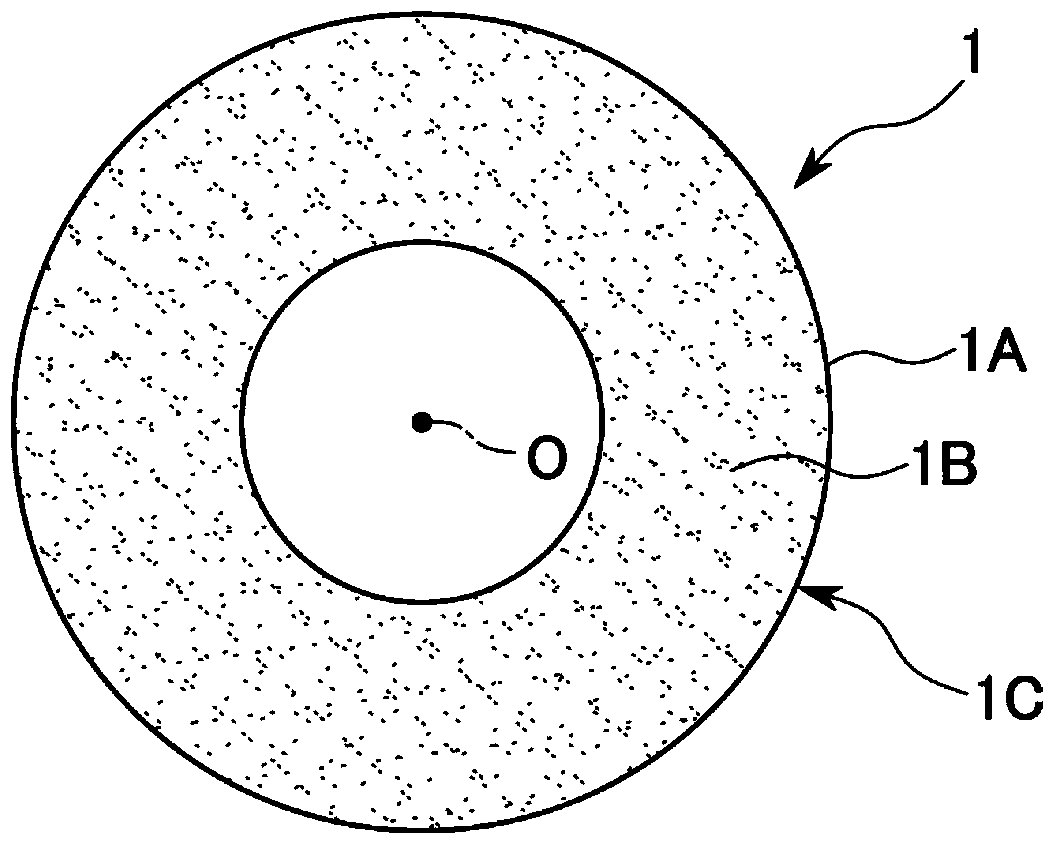

no. 1 Embodiment

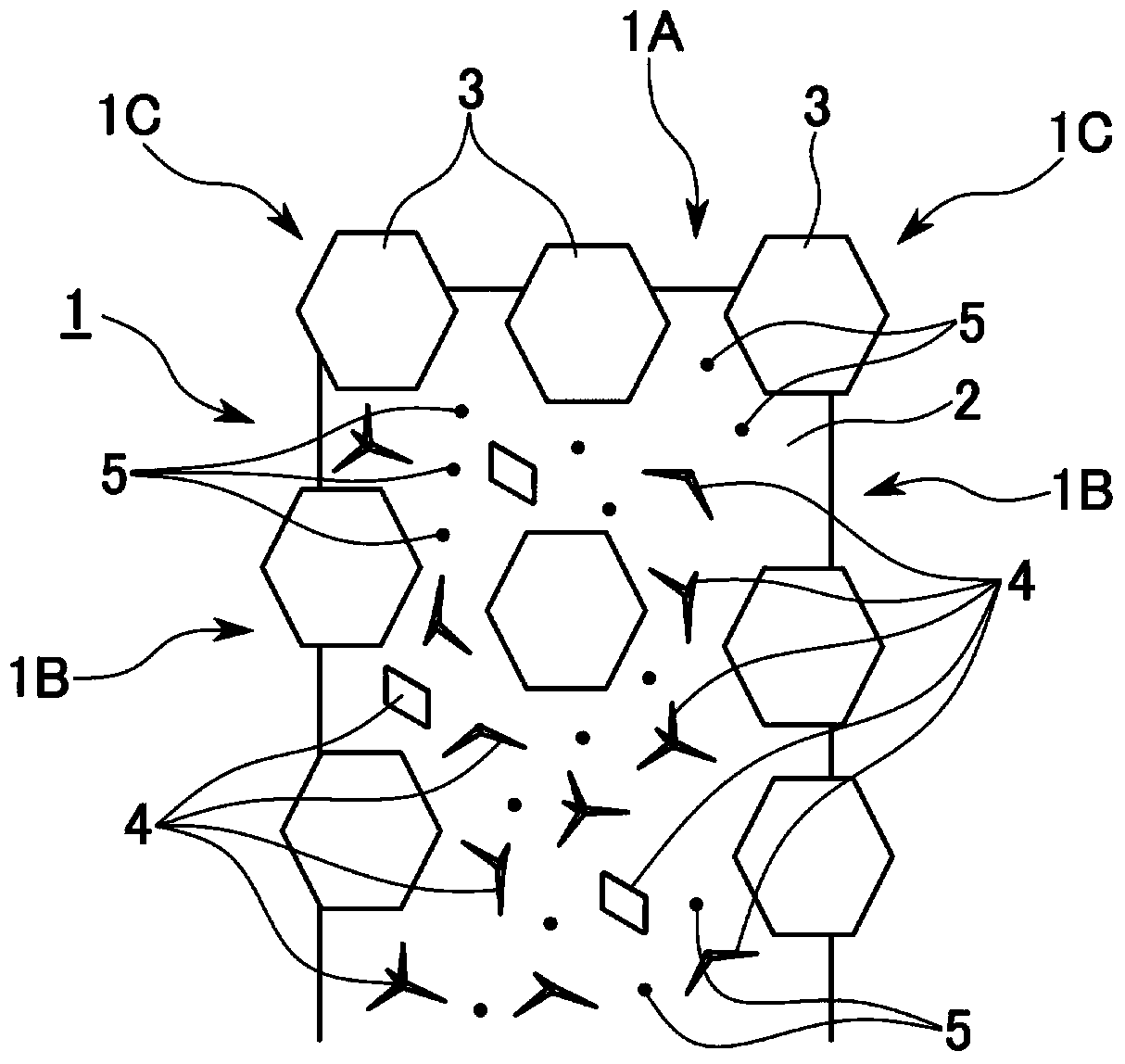

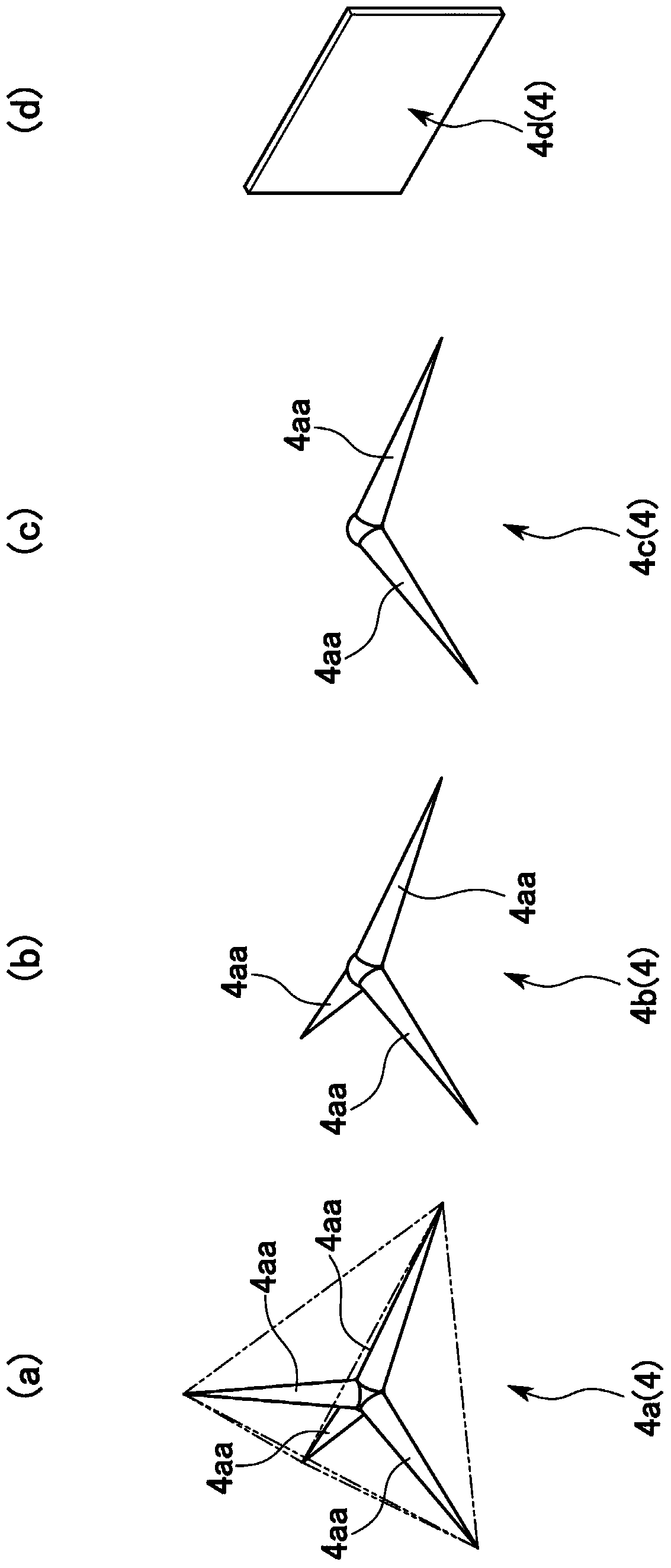

[0067]In this example, eight types of grinding wheel pieces for cutting were prepared with powdered WC filler 5 having a constant content (25%) and varying the addition ratio of filler 4 as a zinc oxide crystal structure, in the resin bond phase 2 A grinding wheel sheet for cutting in which the silane coupling agent is not mixed and the zinc oxide crystal structure filler 4 is added at a rate of 10%, and the resin bond phase 2 is not mixed with a silane coupling agent and the zinc oxide crystal structure is The addition ratio of the filler 4 is set to 35% and the grinding wheel sheet for cutting does not contain the filler 5 in WC powder form, so there are ten kinds of grinding wheel sheets for cutting according to the present invention. The grinding wheel sheet for cutting has an outer diameter of 58 mm, an inner diameter of 40 mm, and a thickness of 0.3 mm. In addition, the resin bond phase 2 is a phenolic resin, and the abrasive 3 is a diamond abrasive with a particle size ...

no. 2 Embodiment

[0099] In this example, using the grinding wheel sheets for cutting in Examples 1 to 10 and Comparative Examples 1 and 2 described in Example 1, in which the compositions of the fillers are different, first, as Figure 4 As shown, the dicing of the QFN in which the Cu lead frame 12 is arranged at intervals in the molding resin 11 is performed. And, at the beginning of its cutting and when cutting 500m, measure the cutting resistance and the amount of wear of the thin blade abrasive layer when cutting 10m, and observe the cut surface to measure the size of the burrs extending from the Cu lead frame 12 (such as Figure 4 As shown, let the dimension of the burr extending laterally (feed direction) be X, and the dimension of the burr extending upward be Y). These results are shown in Table 7 at the initial stage of cutting, and in Table 8 at the time of 500-m cutting. In addition, cutting resistance was measured as the load current (A) of the motor which rotates the main shaft of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap