Method for treating hydrophobic organic waste gas by utilizing silicone oil reinforced biological method

An organic waste gas, hydrophobic technology, applied in chemical instruments and methods, separation methods, air quality improvement and other directions, can solve the problems of insoluble in water, cumbersome operation, limited mass transfer rate, etc., to increase the scope of application, improve Processing efficiency, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

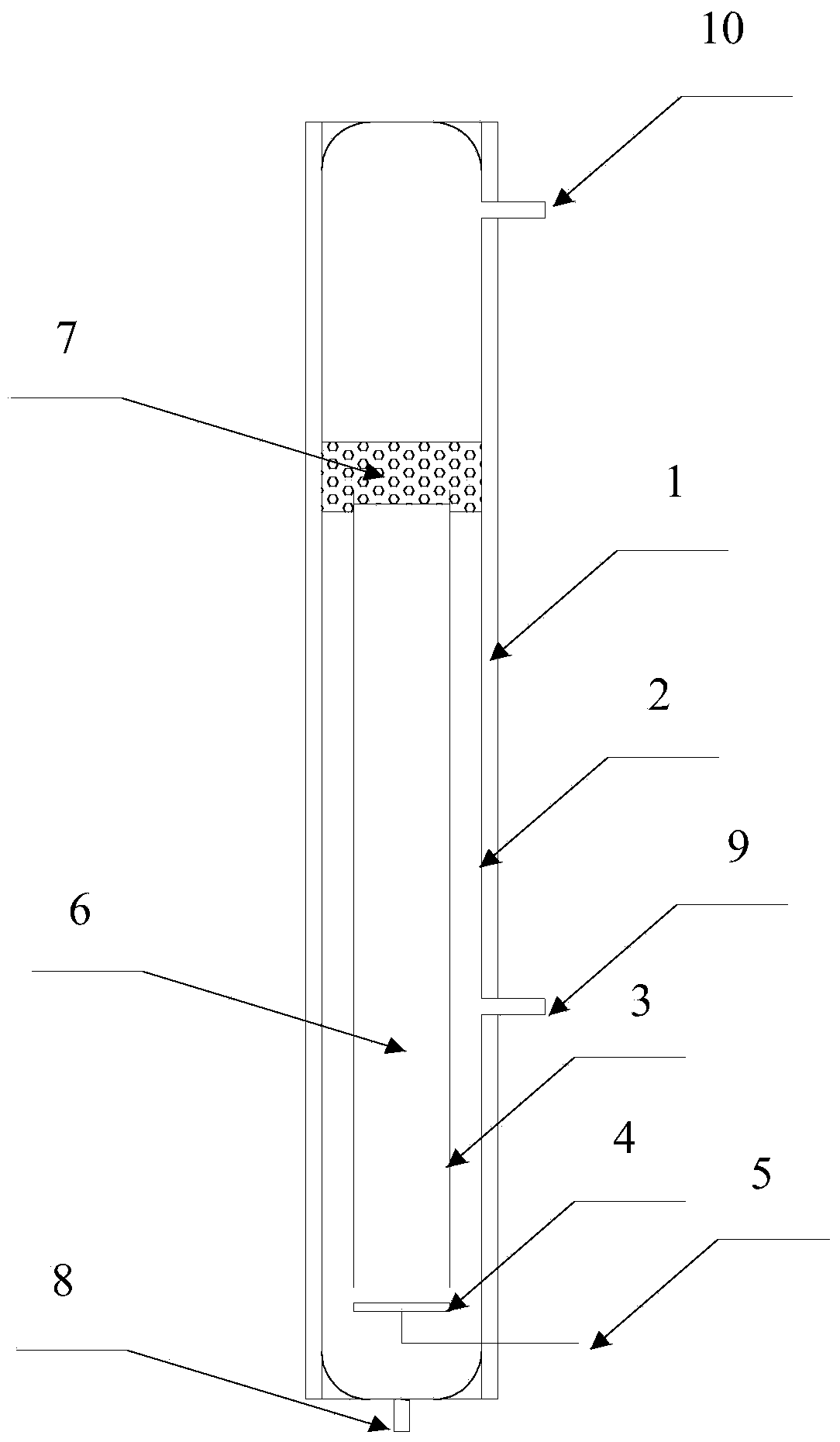

[0045] Experimental conditions: The simulated organic waste gas in the experiment is xylene waste gas, gas composition: xylene + air, obtained by bubbling with an air pump. The concentration of organic waste gas is controlled at 200-2000mg / m 3 between. The bioreactor in the experiment is an airlift bioreactor, such as figure 1 shown. The diameter of the outer cylinder of the reactor is 60mm, and the height is 630mm; the diameter of the guide cylinder is 30mm, and the height is 400mm. The volume of the whole reactor is 1.78L. The bacteria solution is composed of Pandoraea strains and nutrient solution. Mineral Salt Medium (MSM) was obtained by diluting 10mL of solution A and 20mL of solution B to 1L. Among them, liquid A contains 200g (NH4) 2 SO 4 ,10g MgCl 2 ·6H 2 O, 1g EDTA, 0.2g ZnSO 4 ·7H 2 O, 0.1g CaCl 2 2H 2 O, 0.5g FeSO 4 ·7H 2 O, 0.02g Na 2 MoO 4 2H 2 O,0.02gCuSO 4 ·5H 2 O, 0.04g CoCl 2 ·6H 2 O and 0.1 g MnCl 2 2H 2 O, etc., dilute to 1L after di...

Embodiment 2

[0050] Experimental conditions: The simulated exhaust gas in the experiment is xylene exhaust gas, the gas composition: xylene + air, obtained by bubbling with an air pump. The concentration is controlled at 200~2000mg / m 3 between. The bioreactor in the experiment is an airlift reactor, such as figure 1 shown. The diameter of the outer cylinder is 60mm and the height is 630mm; the diameter of the guide cylinder is 30mm and the height is 400mm. The volume of the whole reactor is 1.78L. The bacteria solution is composed of Pandoraea strains and nutrient solution. Mineral Salt Medium (MSM) was obtained by diluting 10mL of solution A and 20mL of solution B to 1L. Among them, liquid A contains 200g (NH4) 2 SO 4 ,10g MgCl 2 ·6H 2 O, 1g EDTA, 0.2g ZnSO 4 ·7H 2 O, 0.1g CaCl 2 2H 2 O,0.5gFeSO 4 ·7H 2 O, 0.02g Na 2 MoO 4 2H 2 O, 0.02g CuSO 4 ·5H 2 O, 0.04g CoCl 2 ·6H 2 O and 0.1 g MnCl 2 2H 2 O, etc., dilute to 1L after dissolving; B solution is 155g K 2 HPO 4 ...

Embodiment 3

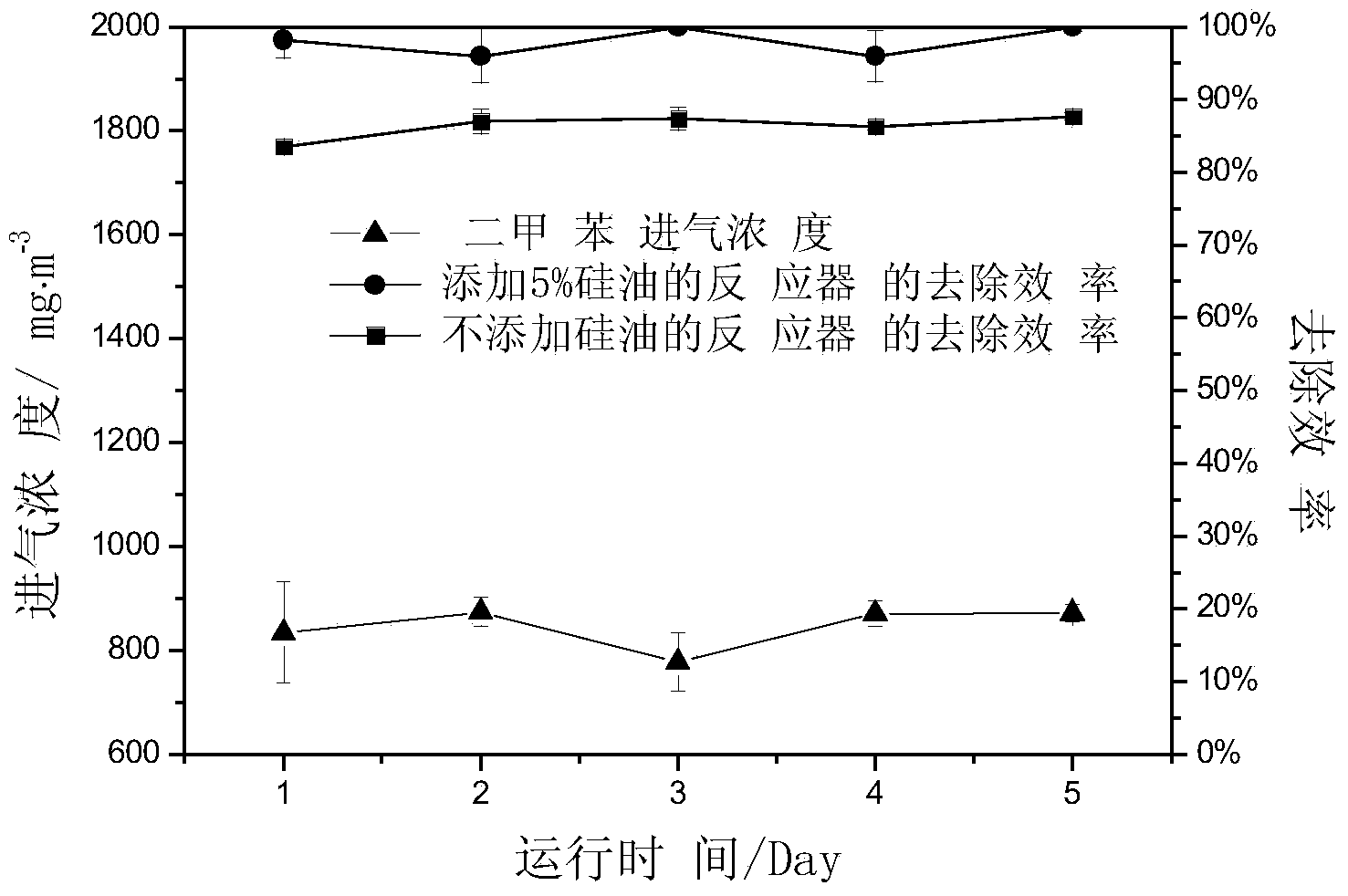

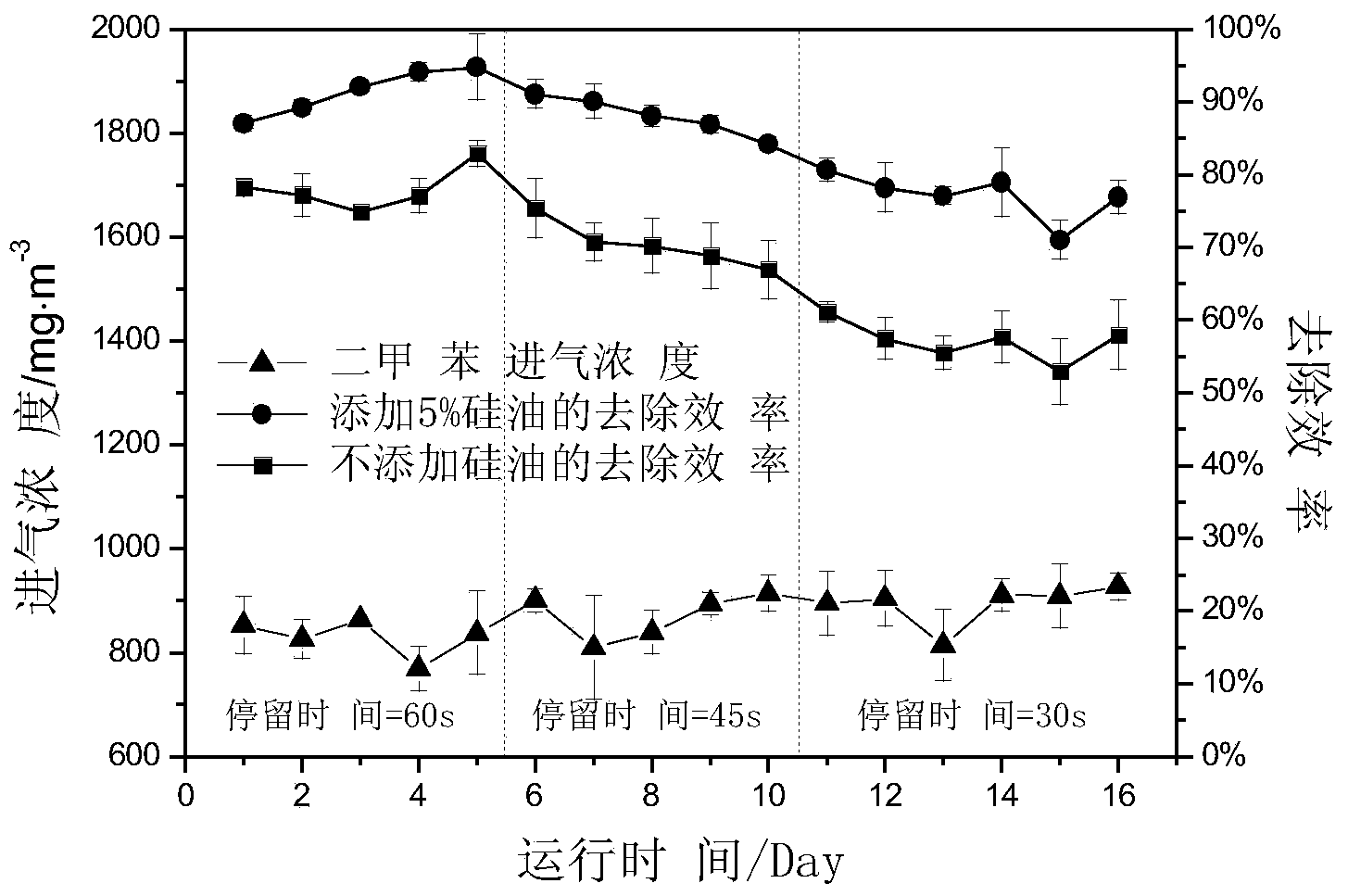

[0054] Experimental conditions: The simulated exhaust gas in the experiment is xylene exhaust gas, the gas composition: xylene + air, obtained by bubbling with an air pump. The concentration is controlled at 200~2000mg / m 3 between. The bioreactor in the experiment is an airlift reactor, such as figure 1 shown. The diameter of the outer cylinder is 60mm and the height is 630mm; the diameter of the guide cylinder is 30mm and the height is 400mm. The volume of the whole reactor is 1.78L. The bacteria solution is composed of Pandoraea strains and nutrient solution. In the two air-lift bioreactors that are stable under the same conditions, add the absorption liquid mixed with bacteria liquid and silicone oil to one of the reactors, and the amount of silicone oil added accounts for 5% (volume) of the total absorption liquid. Ratio), add a separate bacterial solution without silicone oil to another reactor. Mineral Salt Medium (MSM) was obtained by diluting 10mL of solution A a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com