Metal mold and manufacturing method thereof, and metal mold casting apparatus

A technology of metal mold and metal mold casting, which is applied in the direction of casting equipment, casting molding equipment, metal processing equipment, etc. It can solve the problems of high operating temperature and ambient temperature, increasing casting size casting allowance, slow hydraulic transmission speed, etc. problems, to achieve the effect of shortening the casting time, improving the yield, and avoiding insufficient casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

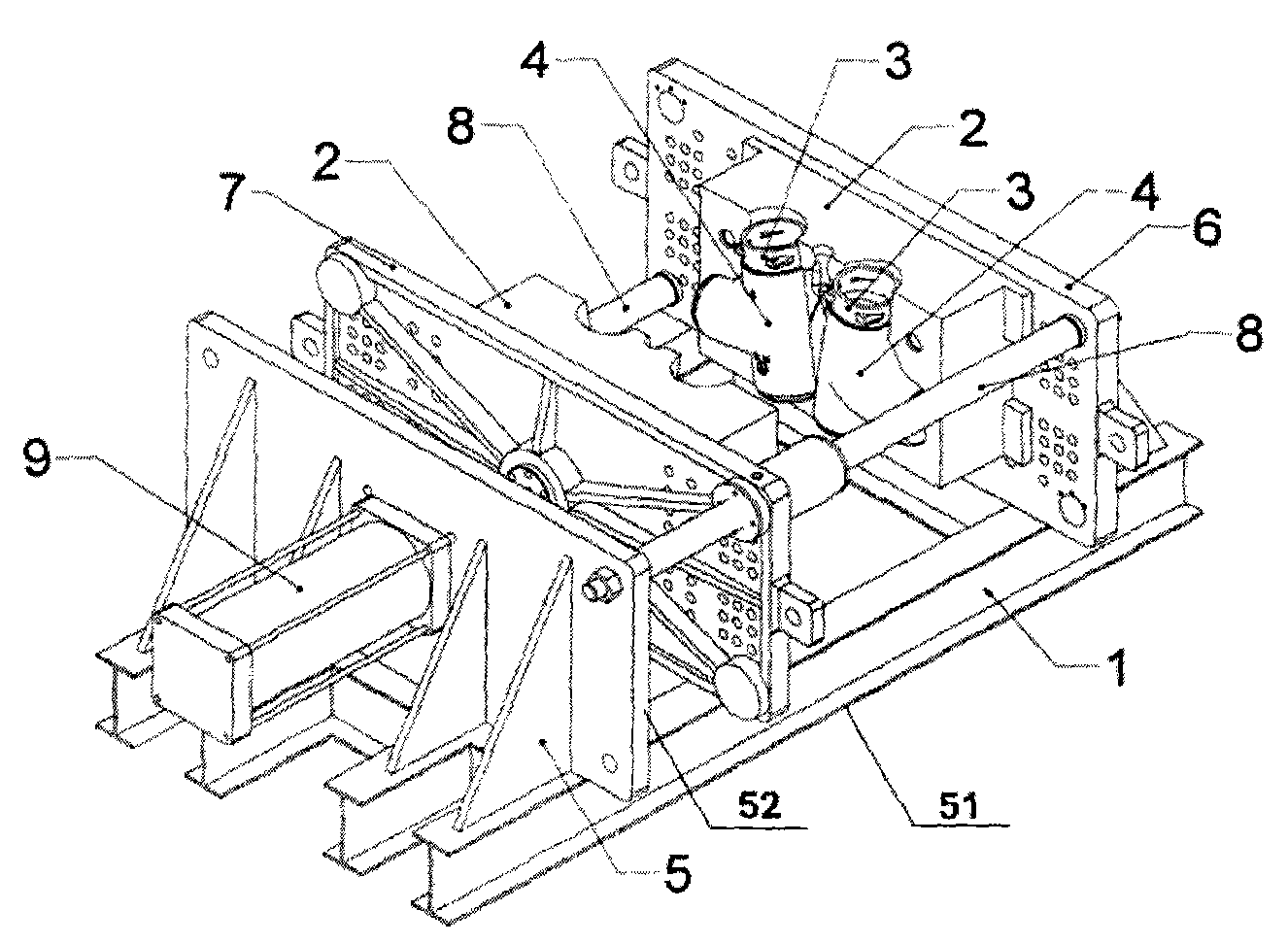

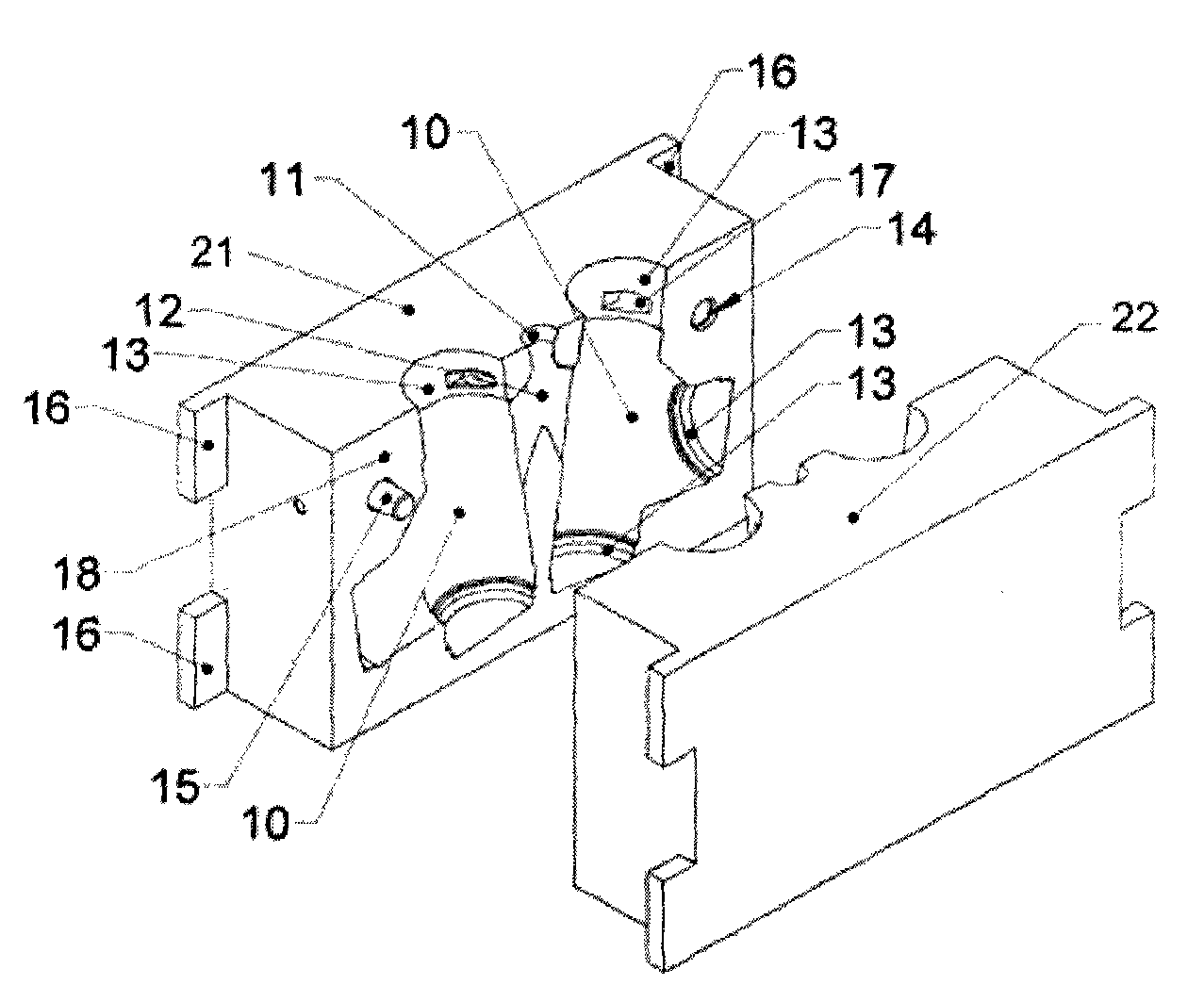

[0113] refer to figure 1 and figure 2 , which respectively show the structure of the metal mold of this embodiment and the structure of the metal mold casting equipment using the metal mold of this embodiment.

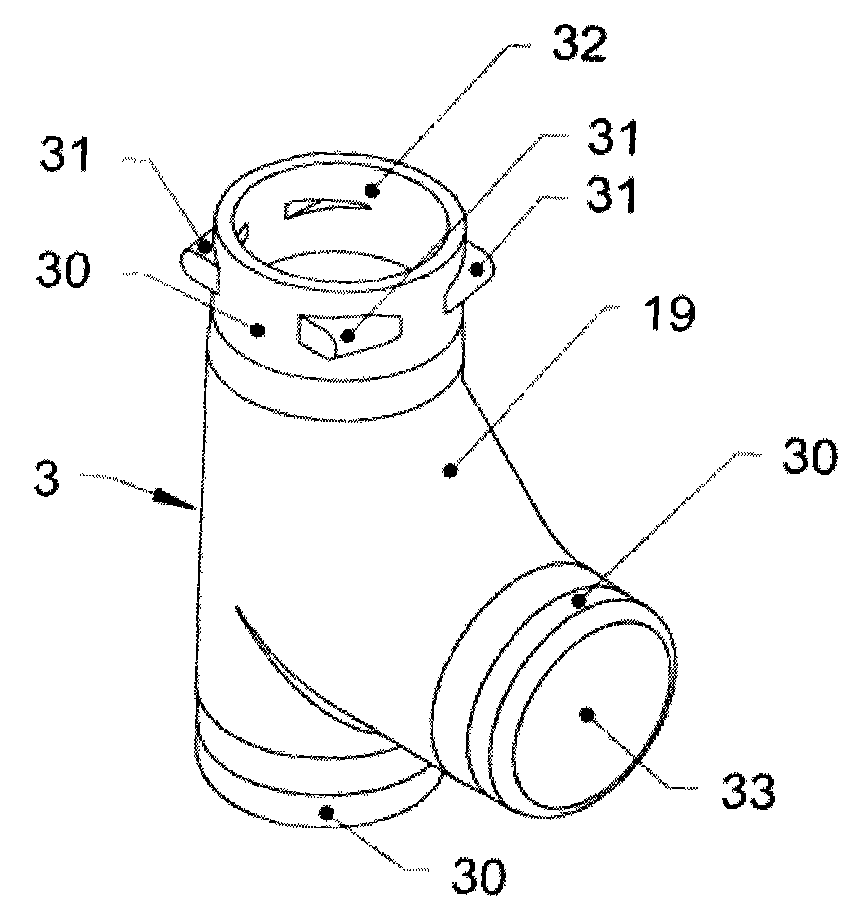

[0114] In this embodiment, the metal mold includes: a first half mold 21 and a second half mold 22 . The first half-mold 21 and the second half-mold 22 are correspondingly provided with: a cavity 10 for forming the shape of the casting when casting, a gate 11, a runner 12, a fixed leg 16, a parting surface 18, and a mold for defining the shape of the casting And the sand core 3 described in the above-mentioned embodiments according to the wall thickness.

[0115] Wherein, the mold cavity 10 is a concave cavity conforming to the shape of the outer surface of the casting. The gates 11 are respectively arranged above the first half-mold 21 and the second half-mold 22 , and the runners 12 communicate with the gates 11 and extend from the upper part of the cavity 10 int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com