Mold core preparation method of closed twisted blade

A closed, vane technology, applied in cores, casting molding equipment, casting molds, etc., can solve the problems affecting the static balance efficiency and life of the pump, the large difference in the shape of the vanes, and reduce the surface roughness value, etc., to avoid cold The effect of eliminating defects, smooth impeller blades, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] see Figure 1-Figure 7 , the present invention provides a technical solution: a core preparation method for closed twisted blades, the core preparation steps are as follows:

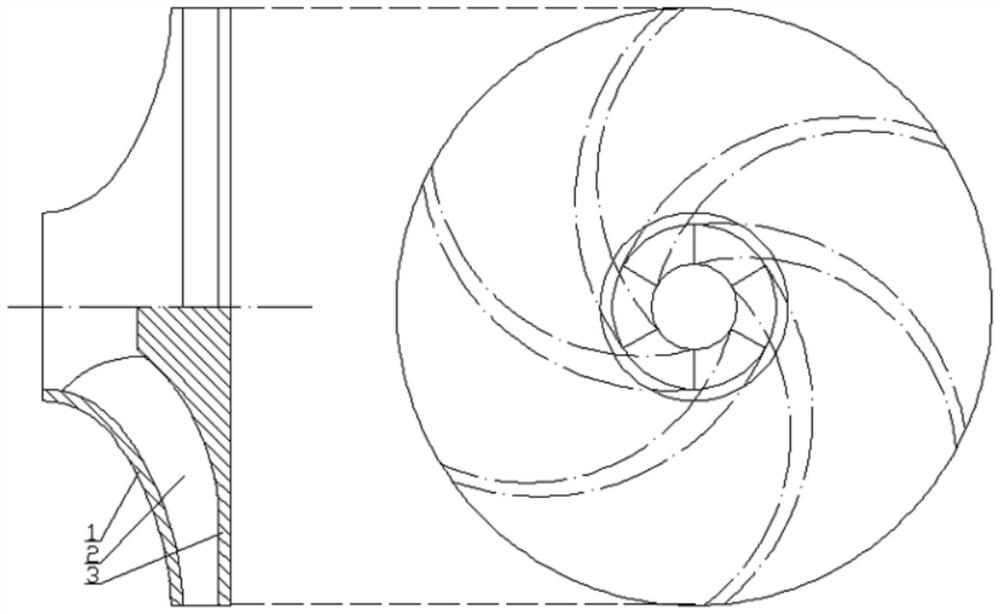

[0034] a. First, carry out the modeling and design model of the impeller from the product diagram, refer to figure 1 ;

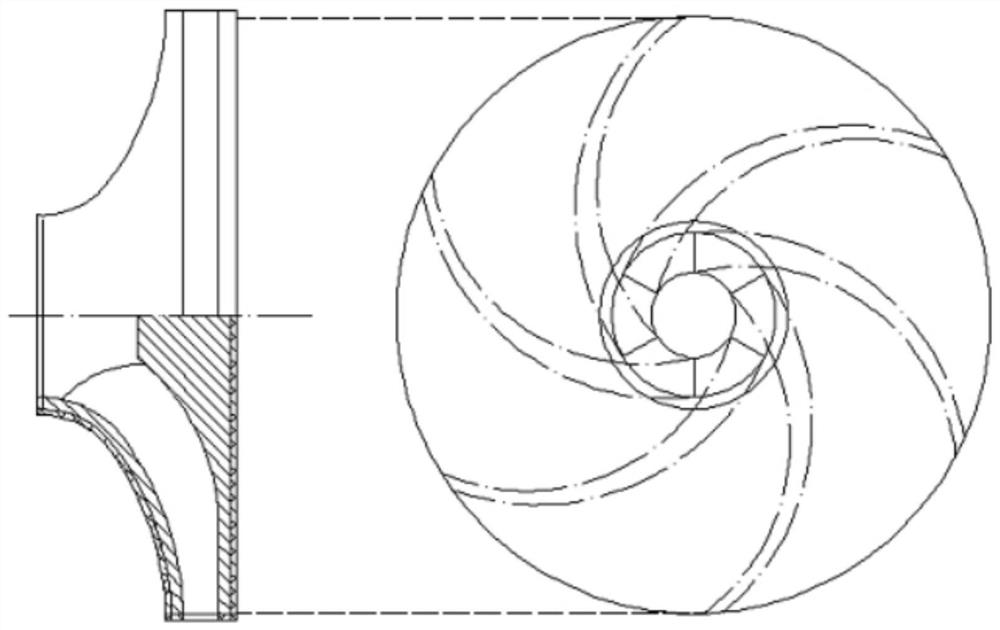

[0035] b. After step a is completed, according to the technical requirements of machining, add blank allowance and mend hole (hub) to the product, and perform shrinkage treatment according to the type of impeller alloy. figure 2 ;

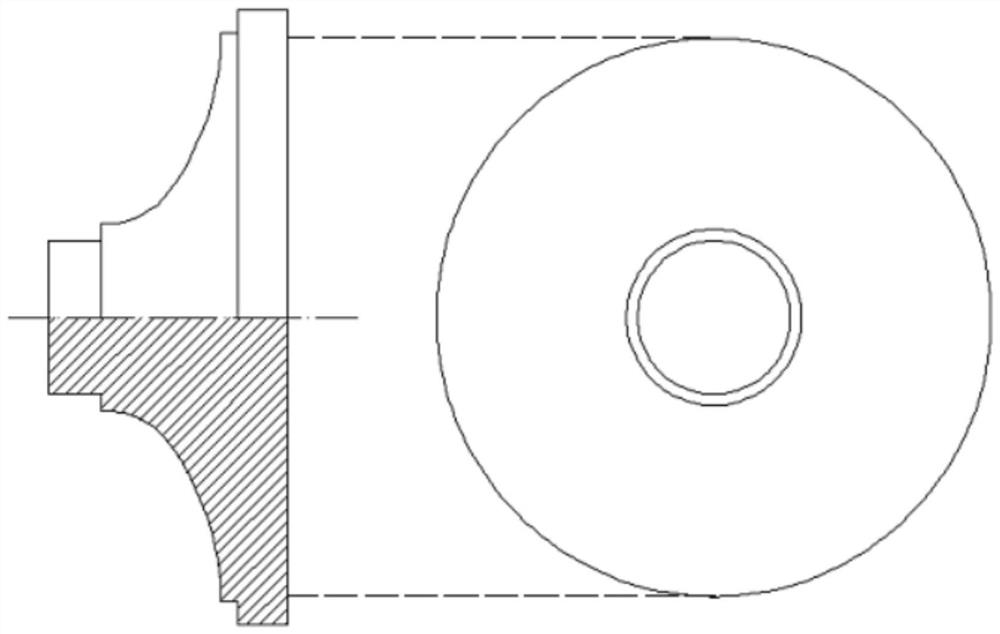

[0036] c. After step b is completed, the outer contour of the blank in the blank A is rotated to model the production solid model, and the core is added to the inlet and outlet of the model and Boolean intersection operation is performed to produce the blank B. refer to image 3 ;

[0037] d. After step c is completed, the blank B is divided into the area blocks corresponding to the number of blades along the blade forming area (each block incl...

Embodiment 1

[0050] Embodiment 1 Closed twisted blade data parameter table 2 is as follows:

[0051] Test items resistance to the pump smoothness Accuracy service life Parameter index generally good higher good

Embodiment 2

[0052] Embodiment two closed twisted blade data parameter table 3 is as follows:

[0053] Test items resistance to the pump smoothness Accuracy service life Parameter index smaller high high long

[0054] In summary, referring to the comparison of the data in Table 1, Table 2 and Table 3, the purpose of the present invention is to provide a combined impeller sand core for the casting production of the impeller. Rotation features, high dimensional accuracy, smooth surface, due to the combination of sand cores, the pouring process can be ventilated smoothly through the combined surface, avoiding insufficient casting of blades and cold insulation defects, reducing waste products, and obtaining cast impellers with excellent performance to reduce the cost of the pump resistance, improve the efficiency of the pump, the core box made by the present invention is simple in structure, low in production cost, convenient in production and operation of sand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com