Numerical control ultrasonic shot peening process method based on dynamic pressure signal adjustment

A dynamic pressure and signal adjustment technology, applied in the field of forming or shape correction, strength ultrasonic shot peening, can solve problems such as sheet metal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

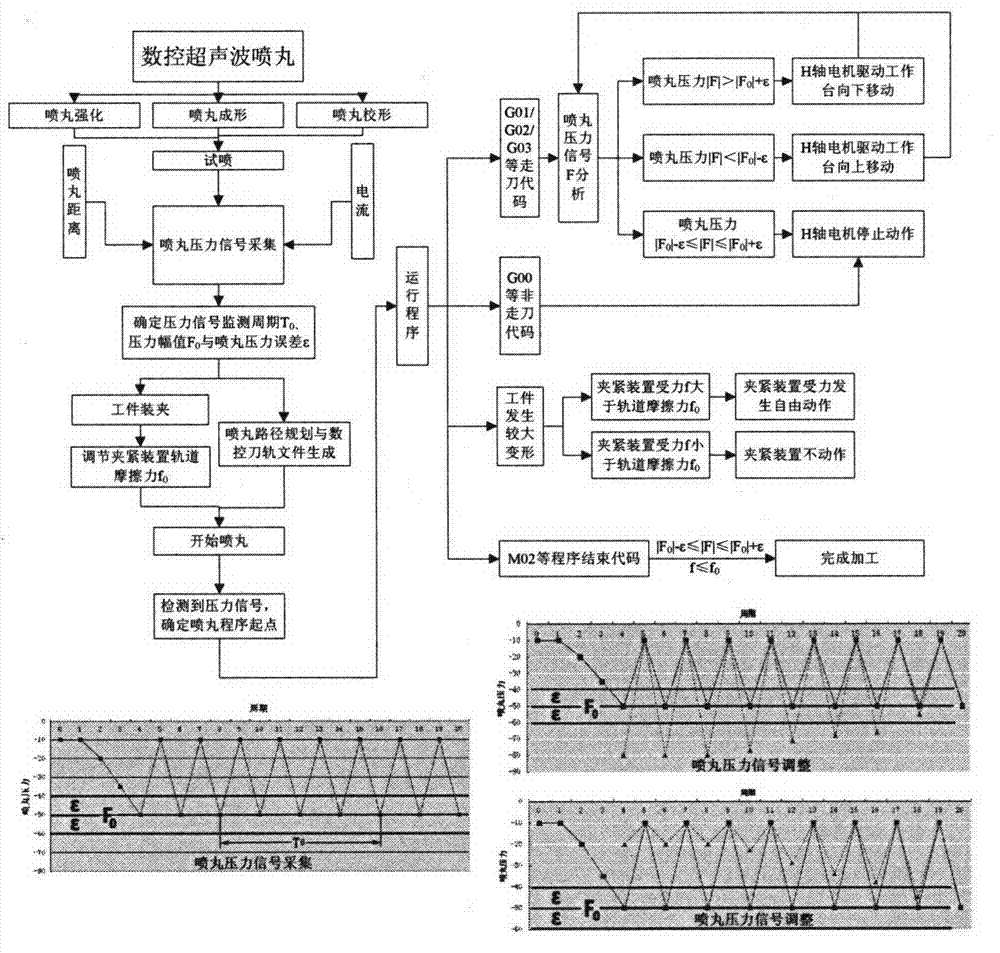

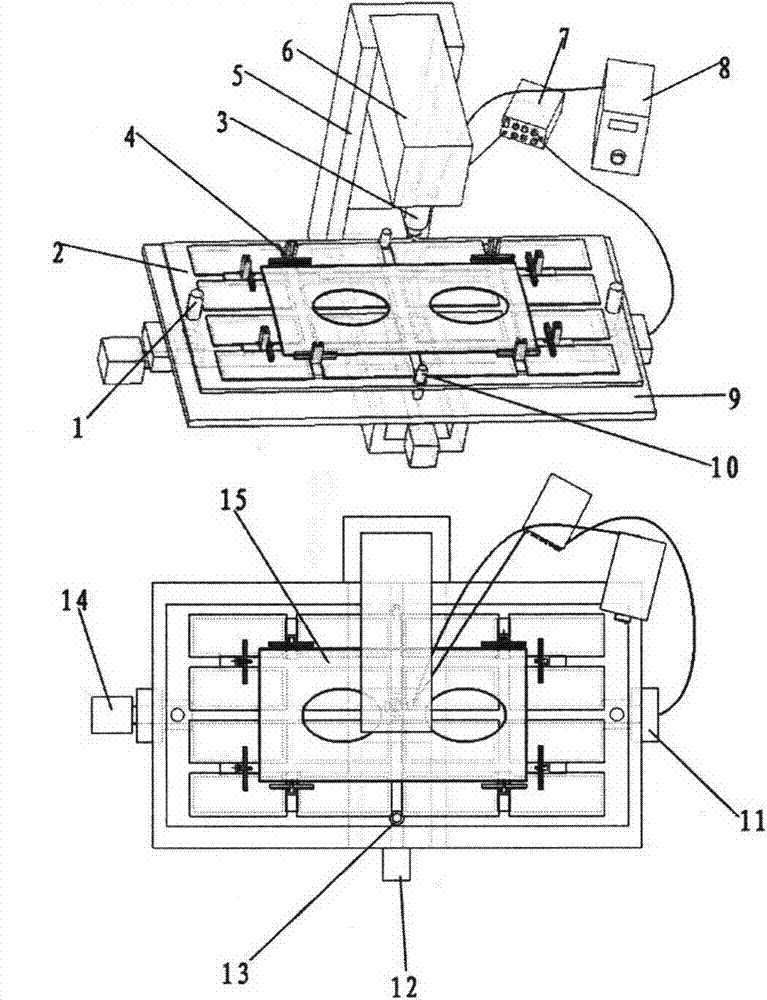

[0033] This example adopts the CNC ultrasonic shot peening process for the overall aviation structural parts. The overall process flow of the process is as follows figure 1 As shown, the clamping before shot peening processing is as follows figure 2 Shown: On the basis of the original three-axis CNC machine tool (parts 5, 6, 9, 12, and 14 in the figure), a "T"-shaped slot lifting table 2 that can move up and down is added, controlled by the H-axis closed-loop servo drive 11 The movement of the lifting platform in the Z-axis direction is ensured by the cooperation of the guide post and guide sleeve (10, 13) to ensure its relative motion accuracy; the dynamic signal test and analysis system 7 monitors, analyzes and calculates the shot peening pressure in the ultrasonic shot peening tool head 3 in real time Signal, the calculation result is sent to the H-axis servo drive 11 as the drive signal; eight dynamic clamping devices 4 are used to clamp and fix the edge of the workpiece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com